Cummins ISX Dual Cam Parts - Cylinder Head Section

Loading...

Loading... Cummins ISX Dual Cam Parts – Cylinder Head Section

The Cummins ISX Dual Cam engine stands as one of the most sophisticated heavy-duty diesel engines ever produced by Cummins. Designed with dual overhead camshafts, it combines advanced airflow management, precise valve timing, and optimized fuel injection control to deliver maximum performance, efficiency, and reliability. These engines are commonly found in heavy trucks, construction machinery, generators, and industrial power systems where uptime and durability are critical.

Maintaining or rebuilding an ISX Dual Cam engine requires precision parts that meet Cummins’ strict engineering specifications. At Diesel Pro Power, every cylinder head and related component in this catalog is carefully selected to ensure direct fit, OEM-grade performance, and long-term dependability. With more than 40,000 satisfied customers worldwide, Diesel Pro has built a reputation as the go-to supplier for high-quality Cummins replacement parts, all backed by fast global shipping and expert customer support.

Cylinder Head Assemblies for Cummins ISX Dual Cam

New Cylinder Head – With Valves Installed

The complete cylinder head assembly for the Cummins ISX Dual Cam is built to restore your engine’s original power and efficiency. This new head comes with valves pre-installed for easy installation and factory-accurate valve seating. It is designed for engines that feature dual overhead camshafts, meaning each head uses two camshafts—one for valve operation and another for fuel injector control.

Key Features:

-

Fully machined and pressure-tested cast-iron construction for superior durability.

-

Includes intake and exhaust valves precision-fitted and tested for seal integrity.

-

Ideal for replacing cracked, warped, or damaged heads that cause compression loss.

-

Compatible with both ISX and QSX-series dual cam engines.

Performance Benefits:

A new cylinder head ensures proper compression across all cylinders, improved combustion efficiency, and restored fuel economy. The design supports consistent airflow at high boost levels, maintaining low exhaust temperatures and optimizing horsepower output even under demanding load cycles.

Understanding the Dual Overhead Camshaft (DOHC) Advantage

The dual camshaft configuration sets this ISX variant apart from earlier single-cam engines. Each camshaft in the head has a dedicated function:

-

One operates the intake and exhaust valves, ensuring exact timing for airflow management.

-

The second controls the injector rockers, delivering precise fuel metering and spray pattern accuracy.

Benefits of Dual Cam Design:

-

Reduced stress on cam followers and pushrods, resulting in longer component life.

-

Enhanced fuel efficiency through fine control of valve and injection events.

-

Improved cold-start performance and emissions compliance.

-

Greater reliability under sustained high-load conditions.

This separation of functions makes the ISX Dual Cam especially well-suited for modern emissions systems and high-horsepower applications where precision timing is essential.

Cylinder Head Installation Hardware

Head Bolt Kits for Cummins ISX Dual Cam

Proper head bolt installation is vital for maintaining a tight seal between the block and head. The head bolt kit includes all the fasteners needed for a complete cylinder head installation. Each bolt is manufactured from high-tensile-strength steel and coated to resist corrosion.

Why Replace Head Bolts During Reassembly:

Head bolts on Cummins ISX engines are torque-to-yield, meaning they stretch slightly when tightened to specification. Once used, they should not be reused because they lose elasticity and may not provide the required clamping force. New bolts ensure uniform torque, prevent head-gasket failure, and maintain even pressure across the entire head surface.

Installation Tip:

Always tighten the bolts following Cummins’ recommended sequence and torque-angle procedure. Proper clamping ensures that the head gasket seals combustion pressure and coolant passages correctly.

Valvetrain Components

High-performance intake valves are critical for allowing air to enter the combustion chamber smoothly and efficiently. Each valve is constructed from corrosion-resistant stainless steel and precision-machined to ensure accurate seating.

Key Characteristics:

-

Polished stems minimize friction and wear in the valve guides.

-

Hardened tips increase durability under constant motion.

-

Perfect fit ensures even air distribution and balanced combustion.

Replacing worn intake valves restores optimal airflow, boosts power, and improves throttle response while reducing fuel consumption.

Exhaust valves handle extreme heat as they release burnt gases from the combustion chamber. They are made from heat-resistant alloys capable of maintaining shape and strength under high temperatures and exhaust backpressure.

Advantages:

-

Designed to resist pitting, corrosion, and seat erosion.

-

Maintains a tight seal to prevent blow-by and loss of compression.

-

Reduces emissions and supports consistent turbocharger performance.

Valve guides ensure that each valve moves precisely within the cylinder head. Worn guides can cause oil leakage, poor sealing, and erratic valve operation.

Guide Features:

-

Machined to tight tolerances to maintain valve alignment.

-

Made from a durable bronze-based alloy for improved heat transfer.

-

Essential for smooth valve motion and oil control.

Valve seat inserts provide the surface on which valves seal during operation. Over time, heat and wear can cause the seat to recess into the cylinder head, leading to compression loss.

Why Seat Inserts Are Important:

-

Protect the cylinder head casting from direct contact with hot gases.

-

Provide a replaceable wear surface, extending head life.

-

Maintain consistent sealing pressure for efficient combustion.

Proper valve stem seals prevent engine oil from entering the combustion chamber while still lubricating the valve stems. Quality seals ensure the engine runs cleanly with minimal oil consumption.

Features:

-

Made from heat-resistant Viton or equivalent materials.

-

Fit tightly to both intake and exhaust valve stems.

-

Help prevent blue smoke and fouled injectors caused by oil burning.

Fuel System Integration

The injector tube assembly connects each injector to the fuel system and ensures that pressurized fuel reaches the injector body without leaks. These precision-machined aluminum or steel tubes include sealing components that withstand the extreme pressures of common-rail systems.

Benefits:

-

Leak-free design ensures consistent fuel delivery to each cylinder.

-

Reduces air intrusion, which can cause misfires or hard starting.

-

High-grade materials prevent fatigue cracking and corrosion over time.

Proper installation of new injector tubes and seals ensures stable injection timing and balanced cylinder performance, key to maintaining efficiency in ISX Dual Cam engines.

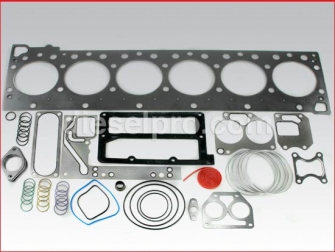

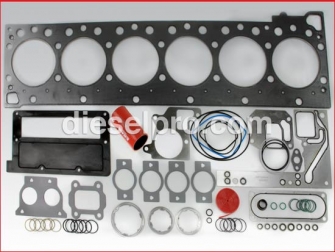

Gasket Sets and Sealing Components

The upper gasket set includes all the gaskets required when reinstalling the cylinder head, including the head gasket, valve cover gaskets, intake and exhaust manifold gaskets, and seals for fuel and coolant passages.

Variants:

-

One version is designed for engines without EGR systems, simplifying installation on pre-EGR configurations.

-

Another version supports EGR-equipped engines, featuring upgraded materials that resist higher exhaust temperatures and coolant flow pressures.

Performance Impact:

Using the correct gasket set ensures complete sealing of all major components, preventing coolant and oil leaks that could compromise engine performance. Proper sealing also maintains compression ratios, which is vital for fuel efficiency and power.

Valve cover gaskets are responsible for keeping the top end of the engine sealed against oil leakage while withstanding high temperatures.

Design Benefits:

-

Manufactured from flexible, oil-resistant materials.

-

Maintain a tight seal even after repeated heat cycles.

-

Prevent oil contamination and protect the camshafts and rocker assemblies from debris.

The vibration isolators mounted on the valve cover reduce noise, vibration, and harshness (NVH) from the upper engine area. Over time, these isolators can harden or crack, leading to increased engine noise.

Updated Versions:

-

Modern isolators for later-model ISX engines use reinforced rubber compounds for better durability.

-

Early versions are available for engines built before 2010, maintaining OEM compatibility for older vehicles.

These small components contribute significantly to driver comfort and overall engine smoothness.

Supporting Components

Maintaining proper engine temperature is crucial for reliability. The temperature switch activates cooling fans or alert systems when the engine reaches a specified temperature threshold, preventing overheating.

Functionality:

-

Automatically closes the circuit when coolant reaches the designated temperature.

-

Designed for high accuracy and compatibility with multiple engine systems.

-

Threaded to fit securely in standard coolant ports.

Although often overlooked, a properly functioning temperature switch helps protect your cylinder head and gasket system from the excessive thermal expansion that can cause cracking or head warpage.

Cylinder Head Rebuild Best Practices

When rebuilding or servicing a Cummins ISX Dual Cam cylinder head, following best practices ensures long-term reliability:

-

Inspect for Cracks and Warpage: Always check the head surface using precision straightedges. Resurface if necessary.

-

Replace All Gaskets and Seals: Old seals harden and may leak under pressure. Always install new gaskets and valve seals.

-

Use New Head Bolts: Torque-to-yield bolts should never be reused. Replace them to ensure proper clamping.

-

Clean Coolant and Oil Passages: Blocked passages cause overheating and poor lubrication.

-

Adjust Valve Lash and Injector Height: Follow Cummins specifications to ensure proper timing and smooth performance.

-

Pressure-Test After Assembly: Confirm that combustion and coolant circuits are sealed before installation.

These steps help prevent common issues such as coolant leaks, compression loss, and early head gasket failure.

Why Buy Your Cummins ISX Dual Cam Cylinder Head from Diesel Pro Power

When it comes to sourcing cylinder heads and related components, Diesel Pro Power stands apart in quality, reliability, and service:

-

Proven Customer Satisfaction: Trusted by over 40,000 customers worldwide.

-

OEM-Level Quality: Every part meets or exceeds original manufacturer standards.

-

Extensive Inventory: Complete selection for ISX and QSX dual cam engines, from bare heads to gasket sets and valve components.

-

Fast Global Shipping: Parts ship quickly and reliably to minimize downtime.

-

Expert Support: Experienced diesel technicians available for product guidance and installation advice.

-

Secure Online Shopping: Streamlined checkout and hassle-free returns.

Diesel Pro Power is committed to helping mechanics, operators, and fleet owners get engines back on the road or back in service fast. Whether you’re replacing a cracked head, performing a full top-end overhaul, or simply refreshing valves and gaskets, the components on this page are built for endurance and precision.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588