Running marine and industrial diesel engines is all about control — knowing exactly what’s happening inside your engine so you can make informed decisions in real time. Whether piloting a tugboat with a Detroit Diesel engine, managing a Cummins-powered barge pusher, overseeing Caterpillar power packs on offshore rigs, or operating John Deere industrial pumps in remote facilities, your success relies on accurate, dependable monitoring. That’s where 12-volt electrical gauges come in. These gauges form the nerve center of your diesel system, providing immediate feedback on critical parameters like oil pressure, coolant temperature, voltage, fuel levels, and engine speed (RPM). Unlike purely mechanical systems, electrical gauges work seamlessly over long distances — from hot, noisy engine rooms to wheelhouses, control cabins, or remote monitoring panels. Why 12-Volt Systems Dominate Marine and Industrial Installations Many marine vessels and industrial diesel systems standardize on 12-volt DC setups. This voltage is robust enough to handle long cable runs typical on ships or across sprawling industrial sites without the complexity or expense of higher voltage conversions. It matches the common battery setups used for engine starting and auxiliary loads, keeping everything streamlined and easy to maintain. With Diesel Pro Power, you get marine-grade and industrial-grade 12-volt electrical gauges that are built to perform reliably under harsh conditions — from salty air to constant vibration to extreme thermal swings. The Relationship Between Senders and Gauges A typical 12-volt electrical gauge system starts with a sender (or transducer) mounted directly on your diesel engine. This could be threaded into the oil gallery for pressure, tapped into coolant jackets for temperature, or installed in a tank for fuel level. As your engine operates, these senders sense real physical changes — pressure, heat, fluid height — and convert them into electrical signals. These small voltage or resistance changes travel through wires to your electrical gauge, where they move a needle or change a digital display. Unlike mechanical systems, which require capillary tubes or direct oil lines, electrical gauges keep hot fluids and moving parts contained at the engine, safely away from your control panels. Why Electrical Gauges Are Ideal for Marine and Industrial Use Distance Flexibility: Long wire runs are simple. You can monitor an engine deep in a ship’s hold from the bridge without bulky or fragile tubing. Reduced Leak Risks: No pressurized oil or vapor lines running through bulkheads, minimizing fire hazards and environmental risks. Cleaner Installs: Wires are easier to route around other systems on crowded engine platforms. Easy Integration: Many modern engine control modules on Detroit Diesel, Cummins, Caterpillar, and John Deere marine or industrial engines are designed to interface directly with electrical gauges. When you source your gauges from Diesel Pro Power, you’re tapping into the world’s largest specialized online supplier of Detroit Diesel, Cummins, Caterpillar, and John Deere engine monitoring solutions for marine and industrial applications. Why choose us? Comprehensive inventory: From 12-volt electrical oil pressure and water temperature gauges to voltmeters, hourmeters, and diesel engine RPM gauges, we carry it all. Marine and industrial focus: Every gauge is selected for durability against vibration, salt, humidity, oil, and heavy-duty industrial cycles. Perfect matches for your engine: We offer gauges calibrated to work with your specific Detroit Diesel, Cummins, Caterpillar, or John Deere senders. Always in stock: No multi-week waits — we ship all orders within 24 hours. Safe transactions: Shop securely on our SSL-protected website with complete data protection. Expert support: Our specialists know diesel engines and marine/industrial demands inside and out. Whether it’s helping select the right Cummins 12V gauge or troubleshooting a Caterpillar sensor wire, we’re ready. 40,000+ satisfied customers worldwide: Trusted by ship operators, port services, dredging fleets, industrial facilities, oilfield managers, and beyond. Why Oil Pressure Monitoring is Non-Negotiable Oil is the lifeblood of every Detroit Diesel marine propulsion engine, Cummins industrial power unit, Caterpillar auxiliary generator, and John Deere irrigation setup. A drop in oil pressure can cause bearing damage in seconds, leading to costly overhauls and extended downtime. How Electrical Oil Pressure Gauges Work An oil pressure sender bolts directly to your engine’s oil gallery. As oil pressure changes, it alters electrical resistance. This signal travels via a dedicated wire back to your 12-volt gauge on the dash or control panel. The result: a live, continuous readout of your lubrication system. Advantages in Marine and Industrial Settings Safer installations: No oil lines running from the engine room to the pilothouse — just clean wiring. Reduced maintenance: Fewer chances of leaks or vibration-induced failures. Long distance-friendly: Whether it’s a 60-foot trawler or a sprawling sand processing plant, wires transmit signals reliably. Keep Your Engine Cool, Keep It Alive Marine and industrial diesel engines generate tremendous heat under load. If coolant flow stops because of a failed water pump, clogged heat exchanger, or ruptured hose, catastrophic damage follows quickly. How They Work Electrical temperature senders thread into your engine’s cooling jacket. As coolant temperature rises, the sender adjusts resistance, sending data back to your 12-volt gauge. This gives operators a live window into engine health. Real-World Uses Detroit Diesel-powered harbor tugs monitoring temps under heavy tow. Cummins-driven dewatering pumps operating in hot climates. Caterpillar 3412 engines pushing loaded dredges. John Deere industrial sets maintaining steady temperatures on long-run irrigation or mining applications. Why Monitor RPM? A diesel engine’s RPM directly influences turbo speeds, piston velocity, and safe operational loads. Over-revving can lead to catastrophic failures — from broken connecting rods to valve collisions. How 12-Volt Tachometers Operate RPM senders (often magnetic pickups or alternator tap signals) feed small voltage pulses to your tachometer. These pulses are converted into a precise needle position on your 12-volt electrical RPM gauge, showing engine speed in real time. Critical for Marine and Industrial Diesel Engines Detroit Diesel mechanical governors often rely on operators watching RPMs closely under load changes. Cummins QSBs on barge pumps use tachometers to maintain optimal flow rates. Caterpillar marine propulsion setups use RPM gauges to avoid overspeed that damages gearboxes. John Deere industrial pump packages ensure engines run within designed specs. Monitor Charging Systems at a Glance Your diesel’s alternator is crucial not just for starting, but also for powering navigation systems, deck hydraulics, lights, sensors, and industrial auxiliary gear. How They Work 12-volt voltmeters connect across your battery system to show live voltage, helping diagnose weak alternators or batteries. Ammeters indicate charging and load draw, alerting operators to electrical imbalances. Vital in Marine and Industrial Applications Keep track of Detroit Diesel starter battery banks under cold-start conditions. Monitor Cummins engine charging circuits running multiple winches. Watch Caterpillar lighting or slurry pumps drawing heavy auxiliary loads. Ensure John Deere control systems have steady power on long irrigation cycles. Never Get Stranded or Interrupt Operations In marine and remote industrial environments, running out of diesel isn’t just an inconvenience — it could leave you adrift or force costly emergency shutdowns. How These Gauges Work Resistive tank senders detect fuel height, sending a corresponding electrical signal to your 12-volt gauge. Operators see exactly how much diesel is available at all times. Examples Across Engine Brands Detroit Diesel-driven cargo boats watching tank levels on multiday runs. Cummins industrial engines in mining avoiding interruptions far from fuel trucks. Caterpillar generator sets on offshore rigs ensuring steady reserves during storms. John Deere water management pumps keeping fields supplied without mid-operation refueling. Why Logging Hours Matters Marine and industrial diesel maintenance schedules are defined by hours — not miles. Oil changes, injector calibrations, valve adjustments, and filter intervals all depend on precise tracking. 12-Volt Electrical Hourmeters Connect to ignition or run circuits to tally actual engine operation time. Keeps maintenance honest and protects your Detroit Diesel, Cummins, Caterpillar, or John Deere system from costly neglect. Why Connections Matter A gauge is only as reliable as the wires and senders linking it to your engine. Poor quality wiring, corroded terminals, or mismatched senders can cause inaccurate readings — or worse, no warnings when you need them most. Diesel Pro Power Solutions We provide marine- and industrial-grade senders designed specifically to match the resistance and voltage ranges of our 12-volt gauges. This ensures your Detroit Diesel oil pressure reading is correct, your Cummins water temp is accurate, and your Caterpillar RPM stays within safe zones. Our wiring harnesses and connector kits are rated for salt exposure, vibration, oil resistance, and thermal extremes — exactly what your John Deere pump systems or offshore vessel requires. Symptoms to Watch For Erratic readings: Often caused by corroded terminals or damaged wires. Gauge stays pinned high or low: Usually indicates a failed sender or broken circuit. No response at all: Could be a disconnected wire, blown fuse, or dead gauge. Basic Troubleshooting Check voltage at the gauge with a multimeter. Inspect sender grounds — poor grounds are a top cause of gauge failures. Test senders by measuring resistance or simulating readings with variable resistors. When you buy from Diesel Pro Power, you’re partnering with a company that understands the stakes. We know your Detroit Diesel propulsion system needs constant oil pressure feedback, that your Cummins dredge pumps demand temperature vigilance, that your Caterpillar generators need hour-accurate maintenance intervals, and that your John Deere irrigation sets can’t afford power fluctuations. Why trust us? Fast shipping within 24 hours anywhere in the world. Precision-matched gauges, senders, and wiring to avoid misreadings. Warranty-backed quality that stands up to marine and industrial abuse. Secure online transactions. Over 40,000 satisfied customers worldwide. Diesel Pro Power makes it easy to outfit your Detroit Diesel, Cummins, Caterpillar, or John Deere marine or industrial engine with the exact 12-volt electrical gauges and connections needed to stay protected and productive. Explore our extensive online catalog, or call us directly at +1-888-433-4735 (USA) or +1-305-545-5588 (International) for personalized help. See why more than 40,000 marine and industrial operators trust Diesel Pro Power to keep their diesel systems running safely and efficiently.

12 Volt Electronic Gauges for Australia

-

Select Parts Category

Loading...

Loading... 12-Volt Electrical Gauges for Detroit Diesel, Cummins, Caterpillar & John Deere Marine and Industrial Engines

Why 12-Volt Electrical Gauges are Essential for Marine and Industrial Diesel Engines

How 12-Volt Electrical Gauges Work with Diesel Engines

The Diesel Pro Power Advantage for 12-Volt Electrical Gauges

Oil Pressure Electrical Gauges for Marine and Industrial Diesel Engines

Water Temperature Electrical Gauges for Engine Cooling Protection

12-Volt Diesel Engine RPM Gauges (Tachometers)

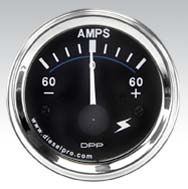

Voltmeter and Ammeter Gauges: Keeping Electrical Systems Healthy

Fuel Level Electrical Gauges for Critical Diesel Monitoring

Hourmeters: Tracking Engine Runtime for Preventative Maintenance

Wiring and Sender Connections: The Heart of Any Electrical Gauge System

Typical Problems with 12-Volt Electrical Gauges and Troubleshooting

The Diesel Pro Power Commitment to Marine and Industrial Operators

Find the Right 12-Volt Electrical Gauges for Your Diesel Engine Today

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588