Gauges For Cummins Engine

Gauge sets from Diesel Pro Power are designed to provide comprehensive monitoring of your Cummins engine. They are easy to install and provide real-time information on engine performance. Diesel Pro Power gauge sets for Cummins engines provide accurate readings and detailed information about your engine’s temperature, pressure, fuel, and other important parameters.

When it comes to Cummins engines, it is important to keep them running at peak performance. That’s why Diesel Pro Power gauge sets are the perfect choice. They provide real-time information on engine performance, allowing you to make informed decisions about when and how to service your engine. The gauge sets feature a variety of sensors that monitor a range of parameters, including temperature, pressure, fuel, and more.

See Gauge Installation Instructions

The gauge sets are designed to be easy to install. They include everything you need to get started, including a panel. Once installed, the gauge sets are designed to be easy to use. The information is presented in an easy-to-read format.The gauge sets from Diesel Pro Power are designed to be durable and reliable. They feature high-quality components and are built to last.

When it comes to monitoring the performance of your Cummins engine, Diesel Pro Power gauge sets are the perfect choice. They provide accurate readings and detailed information about your engine’s performance, allowing you to make informed decisions about when and how to service your engine. With their easy installation and durable construction, Diesel Pro Power gauge sets are the perfect way to keep your Cummins engine running at peak performance.

Installation Of Diesel Pro Power, Inc. Gauges

Diesel pro gauges are a great way to monitor your engine’s performance. They are simple to install and they can help you to monitor your Diesel engine from the engine room to the fly bridge in Marine applications.

The installation process is as follows:

- Remove the dashboard cover.

- Remove the mounting screws that secure the gauge to the dashboard.

- Install the gauge in the desired location.

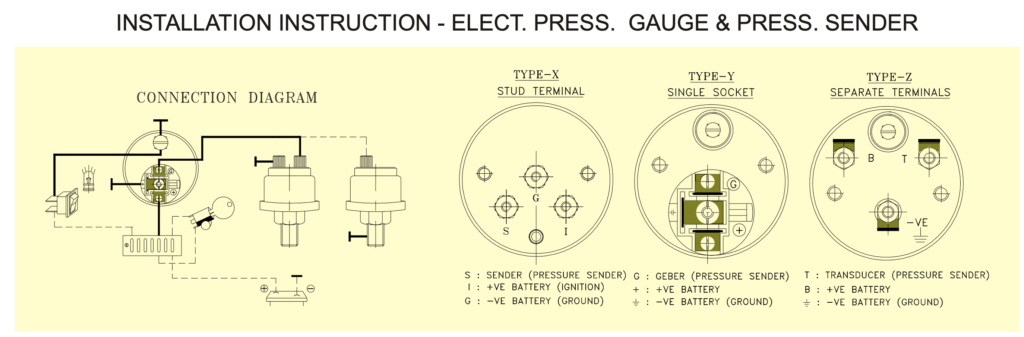

- Connect the wires using the diagrams provided on the website

- Secure the gauge with the mounting screws.

- Replace the dashboard cover.

Mechanical Gauge (Standard) Installation Instructions

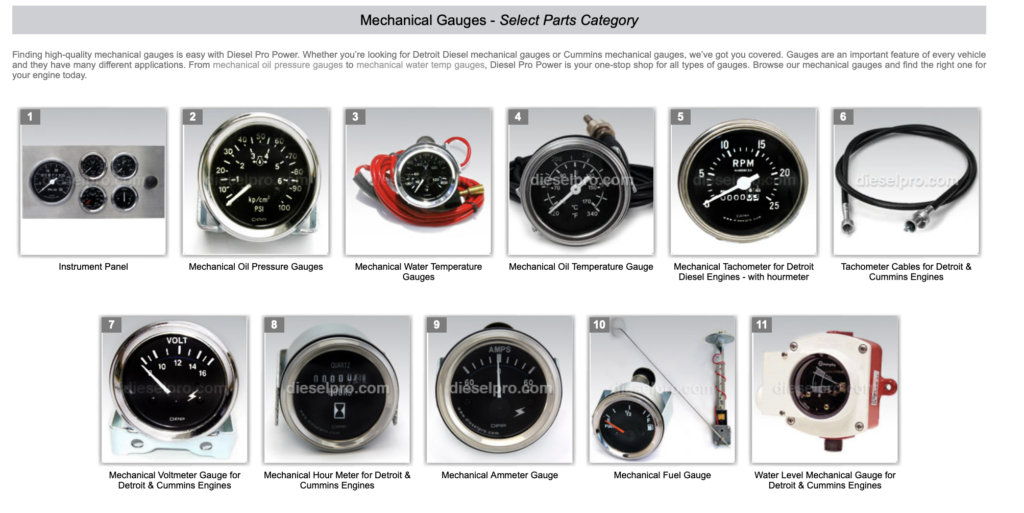

Mechanical gauges remain a trusted choice for marine and industrial operators who value direct, reliable engine monitoring without reliance on electronic sensors or ECM inputs. Proper installation is critical to ensure accurate readings, long service life, and safe operation—especially in marine environments where vibration, heat, and moisture are constant factors. The following instructions apply to a range of mechanical oil pressure, water temperature, oil temperature, tachometer, voltmeter, ammeter, hour meter, fuel level, and liquid level indicator gauges commonly used on Detroit Diesel and other marine engines. These guidelines are intended to help technicians and vessel owners correctly install, route, and secure mechanical gauge lines and electrical connections for dependable performance and clear engine monitoring.

-

- Mechanical Marine Oil Pressure Gauge 400 PSI

- Mechanical Water Temperature Gauge 6 FT

- Mechanical Water Temperature Gauge 12 FT

- Mechanical Water Temperature Gauge 15 FT

- Mechanical Water Temperature Gauge 20 FT

- Mechanical Water Temperature Gauge 30 FT

- Mechanical Water Temperature Gauge 40 FT

- Mechanical Water Temperature Gauge 45 FT

- Mechanical Water Temperature Gauge 50 FT

- Mechanical Oil Temperature Gauge 6FT

- Mechanical Oil Temperature Gauge 12FT

- Mechanical Tachometer for Detroit Diesel Engines – with hourmeter. 1:1 2500 RPM

- Mechanical Tachometer for Detroit Diesel Engines – with hourmeter. LH 1:1 2500 RPM

- Mechanical Tachometer for Detroit Diesel Engines – with hourmeter. RH 1:1 3500 RPM

- Mechanical Tachometer for Detroit Diesel Engines – with hourmeter. RH 1:2 3500 RPM

- 12V Heavy Duty Voltmeter – 2 Inch Dia

- 24 Volt Voltmeter – Heavy Duty – 2 Inch Dia

- Electrical Hour Meter Gauge – 2 Inch Dia – 12/24 Volt

- Electrical Ammeter Gauge – 2 Inch Dia – 12/24 Volt

- Detroit Diesel Fuel Gauge – 12 Volt

- Liquid Level Indicator for Detroit Diesel Engines

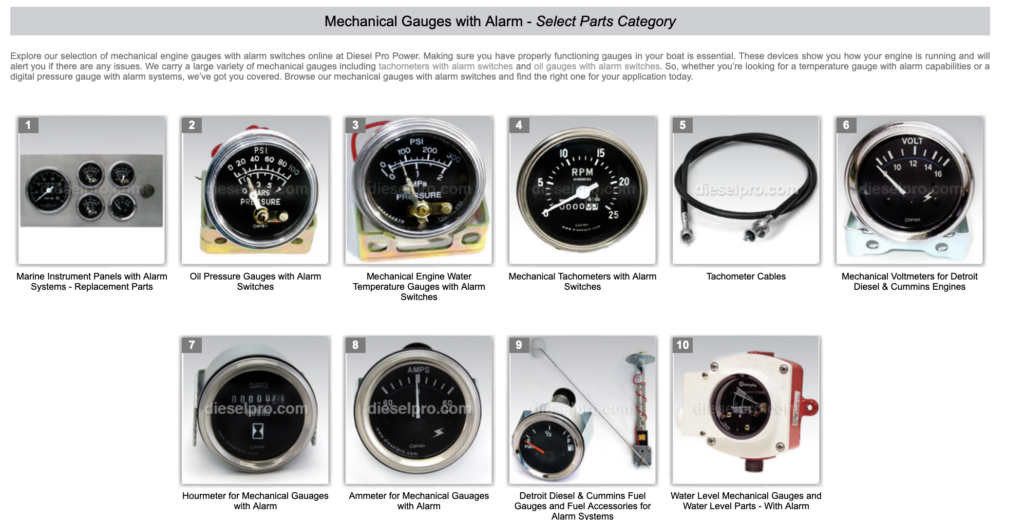

Mechanical Gauge (With Alarm) Installation Instructions

Mechanical gauges equipped with integrated alarm switches provide an added layer of protection by combining accurate, direct-reading instrumentation with audible or visual warnings when critical thresholds are exceeded. In marine and heavy-duty applications, these alarms are essential for alerting operators to potentially damaging conditions such as low oil pressure or high operating temperatures before serious engine damage occurs. Proper installation is especially important to ensure both the gauge and alarm function correctly under vibration, heat, and moisture exposure. The following instructions cover the installation of mechanical oil pressure and water temperature gauges with alarm switches, including engine oil pressure and marine gear oil pressure gauges, across multiple capillary tube lengths. These guidelines are designed to help ensure accurate readings, reliable alarm activation, and long-term durability in demanding marine environments.

- 6 ft Engine water temperature gauge mechanical with alarm switch

- 10 ft Engine water temperature gauge mechanical with alarm switch

- 40 ft Engine water temperature gauge mechanical with alarm switch

Mechanical Tachometer for Detroit Diesel Engines – with hourmeter. 1:1 2500 RPM

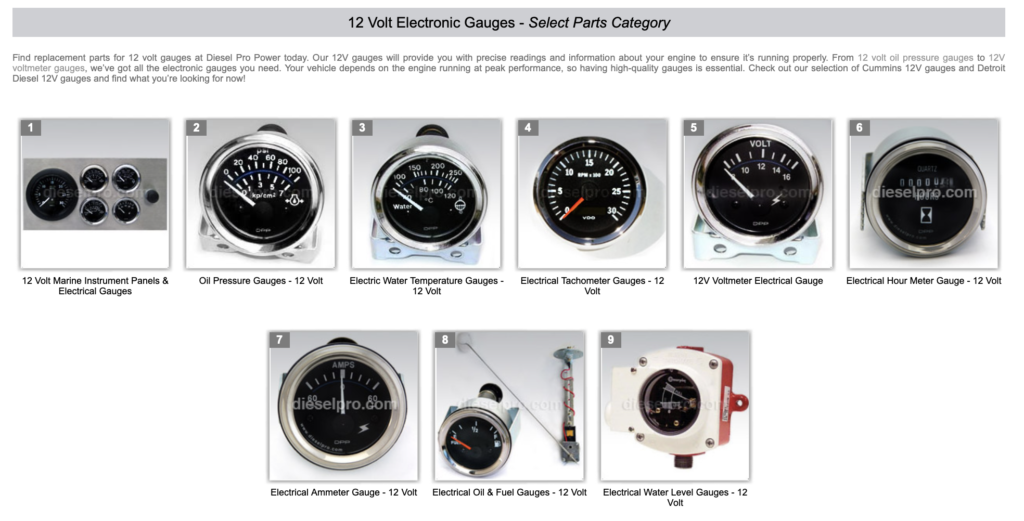

Electrical Gauge (12 Volt) Installation Instructions

Electrical gauges operating on 12-volt systems offer accurate engine monitoring while allowing for flexible mounting, simplified routing, and clean installations commonly preferred in modern marine and industrial applications. Proper installation is essential to ensure reliable readings, stable electrical connections, and long service life—especially in environments exposed to vibration, moisture, and temperature fluctuations. The following instructions cover the installation of 12-volt electrical oil pressure, water temperature, tachometer, voltmeter, hour meter, ammeter, and fuel level gauges, including Detroit Diesel–specific fuel gauges and electric tachometers compatible with both 12- and 24-volt systems. These guidelines are intended to help technicians and vessel owners correctly wire, ground, and calibrate electrical gauges for accurate, dependable engine monitoring.

Electrical Oil Pressure Gauge – 12 Volt

- Marine Gear Oil Pressure Gauge – 12 Volt

- Electrical Water Temperature Gauge – 12 Volt, 0-250c Degrees

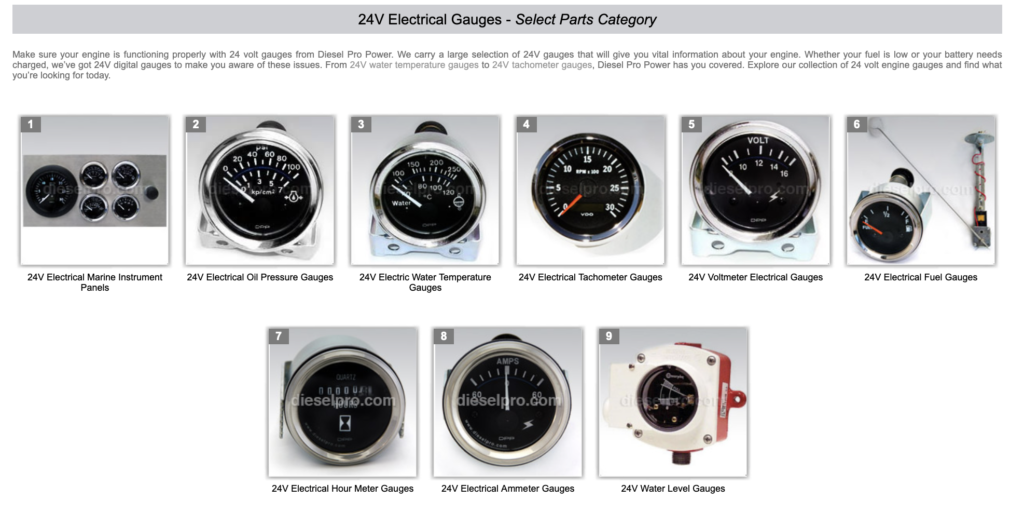

Electrical Gauge (24 Volt) Installation Instructions

Electrical gauges designed for 24-volt systems are commonly used in commercial marine, industrial, and heavy-duty diesel applications where higher-voltage electrical systems are standard. Proper installation is essential to ensure accurate readings, reliable gauge operation, and long-term durability in demanding environments exposed to vibration, heat, and moisture. The following instructions cover the installation of 24-volt electrical oil pressure gauges, marine gear oil pressure gauges, water temperature gauges, electric tachometers, voltmeters, hour meters, ammeters, fuel gauges, and liquid level indicators, including Detroit Diesel–specific instrumentation. These guidelines are intended to help technicians and vessel owners correctly wire, ground, and configure 24-volt electrical gauges for dependable engine monitoring and safe operation.

- Electrical Ammeter Gauge – 2 Inch Dia – 12/24 Volt

- Liquid Level Indicator for Detroit Diesel Engine

Why Marine Professionals Buy Gauges for Cummins Marine Engines from Diesel Pro Power

Accurate engine monitoring is critical on Cummins marine engines, where oil pressure, temperature, RPM, and electrical data directly affect reliability, safety, and engine life. Whether diagnosing a problem, completing a repower, or upgrading an aging instrument panel, choosing the right gauges is just as important as selecting the right engine parts. Diesel Pro Power supplies marine-rated gauges specifically matched to Cummins marine engines, supporting mechanics, fleet owners, and fleet managers with correct fitment, dependable quality, and fast availability. Below is why professionals across the marine industry choose Diesel Pro Power when sourcing gauges for Cummins-powered vessels.

Why Marine Mechanics Buy Gauges for Cummins Marine Engines from Diesel Pro Power

When a Cummins marine engine is down, marine mechanics need gauges that install correctly, read accurately, and hold up in harsh marine environments.

Correct Fitment, First Time

Gauge selection is matched to Cummins engine specifications, sensor ranges, and marine applications to prevent misreadings or rework.Marine-Specific Knowledge

Deep understanding of marine cooling systems, wet exhaust layouts, vibration, and corrosion exposure ensures proper gauge selection.Quality Marine-Rated Gauges

Gauges are built to withstand moisture, salt exposure, and continuous-duty operation.Fast Access to Critical Gauges

Real in-stock inventory and quick shipping help mechanics complete repairs without delays.Technical Support That Speaks Diesel

Experienced support helps with gauge compatibility, sender selection, and installation questions.

Why Fleet Owners Choose Diesel Pro Power for Cummins Marine Gauges

For fleet owners, engine gauges are a risk-management tool that protects assets and prevents costly failures.

Lower Total Cost of Ownership

Durable, accurate gauges reduce the risk of unnoticed engine damage without OEM pricing.Reliable Engine Monitoring

Consistent readings support early detection of oil pressure, temperature, and charging issues.Support for Legacy Cummins Engines

Gauge options remain available for older Cummins marine platforms still in active service.Single Source Convenience

Order gauges alongside filters, injectors, cooling components, and overhaul parts.Global Shipping Capability

Worldwide delivery supports fleets operating across international waters.

Why Fleet Managers Rely on Diesel Pro Power for Cummins Marine Gauges

Fleet managers depend on reliable instrumentation to maintain uptime and standardized monitoring across multiple vessels.

Predictable Maintenance Planning

Accurate gauges support condition-based maintenance and inspection programs.Engine-Specific Gauge Selection

Correct pressure and temperature ranges reduce false alarms and misdiagnosis.Proven Performance in Marine Duty

Gauges are selected for continuous-load marine environments.Reduced Downtime Across Fleets

Fast order processing keeps vessels operational.Trusted Supplier Relationship

Long-term reliability and knowledgeable support simplify fleet-wide instrumentation decisions.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588