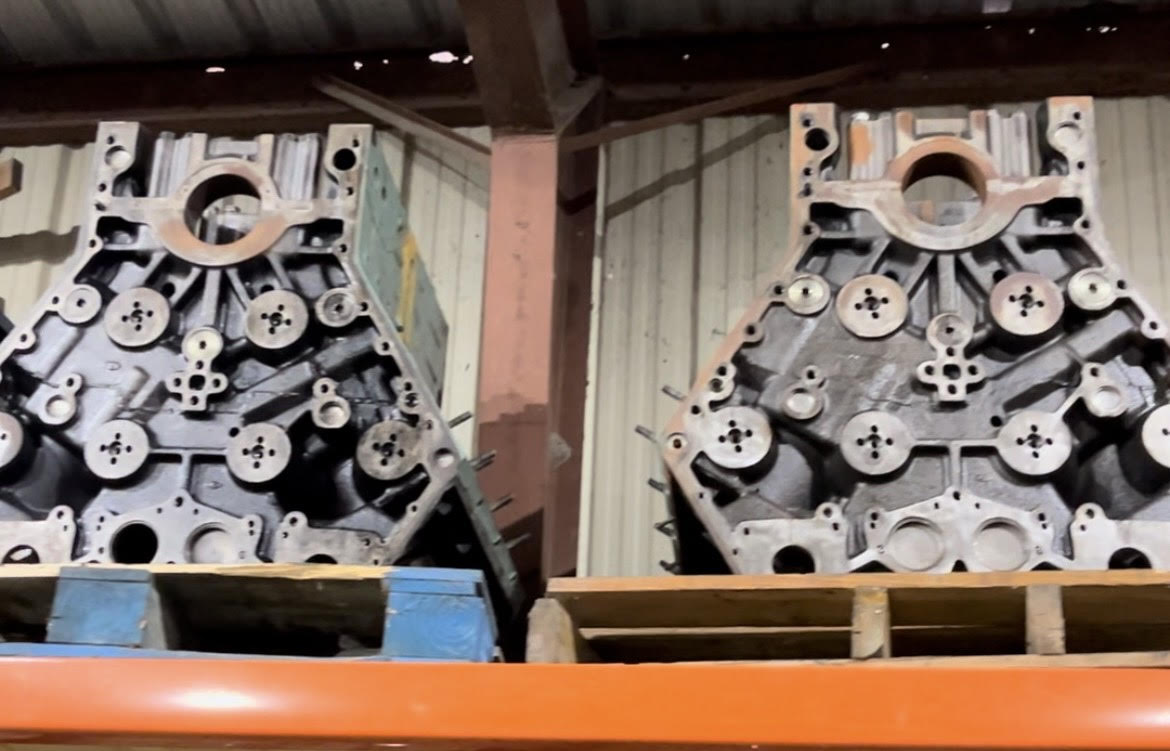

The cylinder block is a foundational component in the Detroit Diesel 149 Series engines (8V149, 12V149, and 16V149), providing the main structural framework for the engine and supporting various critical systems. Its durability and strength are essential for housing key components that generate and control power. Routine maintenance of the cylinder block ensures that the engine operates smoothly and remains reliable for demanding applications. Essential aspects of the cylinder block include its structure and role, maintenance tips, and effective cleaning and testing procedures.

Maintenance Tips: Ensuring Structural Integrity and Performance for Your Detroit Diesel 149 Cylinder Block

Proper maintenance of the Detroit Diesel 149 engine’s cylinder block is essential for preserving its structural integrity and ensuring optimal performance. Routine inspections and preventative measures can identify potential issues early, reducing the risk of costly repairs and engine downtime. Below are some key maintenance tips to keep your cylinder block in top condition.

Inspecting for Cracks and Fractures

The cylinder block endures high temperatures and significant mechanical stresses during operation, making it prone to cracks over time. Focus on the following areas during inspections:

- High-Stress Zones:

Pay close attention to bolt holes, coolant passages, and bearing seats, as these are common areas for stress-induced fractures.

- Inspection Methods:

Use visual inspections for surface-level cracks and dye penetrant testing or ultrasonic testing for detecting hidden fractures.

- Addressing Cracks:

Small cracks should be repaired immediately to prevent them from spreading. Left unchecked, cracks can lead to oil or coolant leaks, compromising the engine’s performance and reliability.

Checking Bearing Caps for Wear

Bearing caps play a crucial role in stabilizing the crankshaft within the cylinder block. Regular monitoring of their condition can prevent severe mechanical issues:

- Signs of Wear:

Look for fretting (surface wear caused by oscillating motion) or loosening of the bearing caps, as these can lead to crankshaft misalignment.

- Proper Fit:

Ensure the bearing caps fit snugly and are secured according to manufacturer specifications. Any signs of wear or deformation should prompt replacement.

- Preventing Further Damage:

Regularly inspecting and replacing worn bearing caps ensures the crankshaft remains aligned, reducing wear on bearings and improving overall engine efficiency.

Monitoring Bolt Torque and Thread Condition

The bolts securing the cylinder head and main bearing caps experience constant stress during engine operation. Neglecting these fasteners can lead to serious issues, including head gasket failure and crankshaft misalignment:

- Torque Checks:

Use a torque wrench to ensure bolts are tightened to the manufacturer’s recommended specifications during routine maintenance. Over-tightening can cause damage, while under-tightening can result in leaks and misalignment.

Torque Specs By Component Thread Size Torque (lb-ft) Torque (N·m) Cylinder Head Bolts 9/16-18 90–100 122–136 Main Bearing Cap Bolts 9/16-12 120–130 163–176 Rocker Arm Shaft Bolts 1/2-13 90–100 122–136 Camshaft Bearing Cap Bolts 1/2-13 90–100 122–136 Blower Hold-Down Bolts 7/16-14 50–55 68–75 Injector Hold-Down Clamp Bolts 7/16-14 46–50 62–68 Exhaust Manifold Nuts 1/2-20 35–40 47–54 Fuel Manifold Connector Nuts 1/2-20 35–40 47–54 Fan Blade to Pulley Hub Bolts 1/2-20 71–75 96–102 Crankshaft Flange Coupling Bolts 7/16-20 70–80 95–108 Flywheel Bolts (Self-Locking) 5/8-18 180–190 244–258 Vibration Damper Bolts 5/8-18 180–190 244–258 Crankshaft Pulley Retainer Bolt 1 1/4-7 450–500 610–678 Camshaft Drive Coupling Bolts 5/16-24 20–25 27–34 Fuel Pump Drive Coupling Retainer Bolts 3/8-24 50–55 68–75 Water Pump to Front Cover Nuts 3/8-24 25–30 34–41 Crankshaft and Camshaft Idler Hub Center Bolt 1/2-13 80–90 108–122 Accessory Drive Pulley Nut 3/4-16 120–140 163–190

- Thread Inspections:

Examine the threads within the block for signs of wear or damage, which could compromise the bolt’s hold.

- Repairing Threads:

For worn or damaged threads, use thread repair kits or inserts to restore the integrity of the connection. This prevents further damage to the cylinder block and ensures a secure fit.

Cleaning Cooling and Lubrication Passages

Blockages in the cylinder block’s cooling and lubrication passages can severely impact engine performance:

- Coolant Passages:

Flush the cooling system regularly to remove debris and scale that may accumulate, obstructing coolant flow and causing overheating.

- Lubrication Channels:

Ensure oil passages remain clean to allow for proper lubrication of the crankshaft, bearings, and other moving parts. Using high-quality oil and replacing oil filters regularly helps maintain cleanliness.

Ensuring Surface Flatness

The cylinder block’s surface must remain perfectly flat to ensure a proper seal with the cylinder head and prevent head gasket failures:

- Flatness Testing:

Use precision straightedges and feeler gauges to check for warping or uneven wear.

- Resurfacing:

If unevenness is detected, have the surface professionally machined to restore flatness.

By incorporating these maintenance practices into your routine, you can prolong the life of your Detroit Diesel 149 cylinder block and ensure consistent engine performance. Preventative care not only reduces the likelihood of mechanical failures but also keeps your engine running efficiently, even in the most demanding applications.

Cleaning and Testing: Maintaining Optimal Condition of the Cylinder Block

Regular cleaning and testing of the cylinder block are critical to maintaining the health and performance of Detroit Diesel 149 Series engines. These procedures ensure that internal passages are free of obstructions, detect potential issues like leaks or structural weaknesses, and prepare the block for optimal operation. A clean, tested cylinder block supports efficient cooling, lubrication, and overall engine reliability.

Solvent Baths for Thorough Cleaning

Solvent baths are an effective method for removing grease, oil, and accumulated contaminants from the cylinder block’s internal and external surfaces.

-

Process:

Submerging the cylinder block in a solvent solution dissolves stubborn deposits of oil, grease, and carbon buildup. This ensures that both visible surfaces and hidden passages, such as lubrication and coolant channels, are thoroughly cleaned.

-

Post-Bath Scrubbing:

After soaking, technicians use brushes or scrubbing tools to remove any remaining residue, paying close attention to critical areas like cylinder bores and bolt holes.

-

Benefits:

This deep-cleaning process prevents obstructions in cooling or lubrication passages, ensuring that the engine operates efficiently and reducing the risk of overheating or oil starvation.

Steam Cleaning to Clear Residual Buildup

Steam cleaning offers a powerful, eco-friendly alternative to chemical solvents for cleaning cylinder blocks.

- High-Temperature Cleaning:

Using high-pressure steam, this method effectively loosens dirt, grease, and contaminants from both the external surfaces and internal passages of the cylinder block. The heat also sanitizes the block, eliminating bacteria or contaminants that could degrade the metal.

- Focus on Cooling and Lubrication Passages:

Steam cleaning is particularly effective for clearing small channels, ensuring that coolant and oil flow freely without obstruction.

- Drying Post-Cleaning:

After steam cleaning, it is essential to thoroughly dry the cylinder block to prevent moisture from causing corrosion, especially in areas that are difficult to access.

Pressure Testing to Detect Leaks and Weaknesses

Pressure testing ensures that the cylinder block can withstand operational stresses and identifies any potential leaks in critical systems.

- Procedure:

Coolant and lubrication passages are sealed, and pressurized air or fluid is applied to simulate operating conditions. This allows technicians to pinpoint any leaks or weaknesses in the block.

- Importance:

Even minor leaks can result in coolant or oil loss, leading to overheating, lubrication failure, or catastrophic engine damage. Pressure testing provides confidence that the cylinder block is secure and ready for use.

- Verification of Seals:

This test also checks the integrity of seals and gaskets, which must remain intact to maintain the block’s performance under high-pressure conditions.

Magnetic Particle Inspection (MPI) for Crack Detection

Magnetic Particle Inspection is a non-destructive testing method used to detect cracks or weaknesses in ferrous materials like cast iron cylinder blocks.

- How It Works:

A magnetic field is applied to the cylinder block, and iron particles are sprinkled onto the surface. Cracks or flaws disrupt the magnetic field, causing the particles to cluster, making the defects visible.

- Critical Areas:

MPI is especially effective for examining high-stress zones, such as around bolt holes, cylinder bores, and mounting points. Detecting these flaws early prevents structural failures that could lead to significant engine issues.

- Non-Invasive Testing:

Since MPI is non-destructive, it preserves the integrity of the block while providing detailed insights into its condition.

Rust Prevention and Protective Coatings

After cleaning and testing, preventive measures are essential to protect the cylinder block from rust and corrosion, especially in marine or humid environments.

- Thorough Drying: Immediately after cleaning, the block must be dried thoroughly to eliminate any residual moisture that could promote rust.

- Rust-Preventive Coatings: A thin layer of rust-preventive oil can be applied to external surfaces to shield the block from environmental exposure. This is particularly important for engines in marine applications, where saltwater can accelerate corrosion.

- Storage Protection: For engines stored for long periods, applying protective coatings and storing the block in a dry, climate-controlled environment minimizes the risk of damage.

By following these maintenance tips and cleaning procedures, technicians can ensure the cylinder block of the Detroit Diesel 149 Series engines remains in optimal condition. Routine inspections and preventive care support the cylinder block’s structural integrity, maintain efficient cooling and lubrication, and extend the engine’s overall lifespan, making it reliable for high-performance applications

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588