-

Introduction To The Detroit Diesel Series 149 Engines (8V149, 12V149, 16V49)

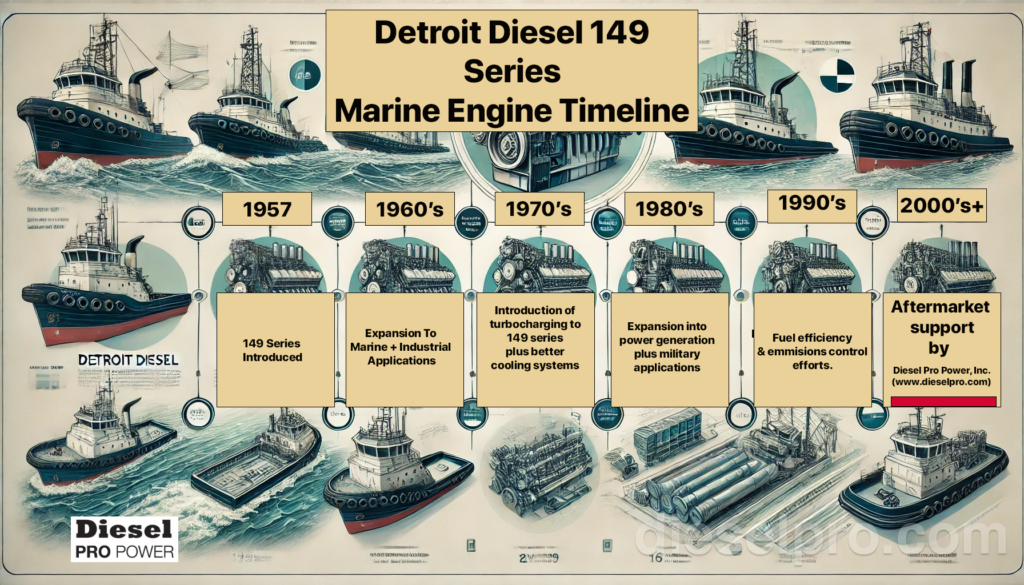

Detroit Diesel 149 Series Engine History

-

Series 149 Overview

Brief history and applications (e.g., marine, industrial, and trucking).

-

Importance of Maintenance

How proper maintenance supports longevity and reliability.

-

Challenges Due to Out-of-Print Manual

Detroit Diesel 149 Series Now Out Of Print Manual

Emphasis on providing practical guidance for essential tasks.

-

Focus on Practical Use:

This guide offers an overview and step-by-step maintenance tips without replacing professional advice or in-depth manual details.

-

-

Understanding the Two-Cycle Diesel Principle In Detroit Diesel 149 Series Engines (8V149, 12V149, 16V49)

-

Two-Stroke Cycle Overview For Detroit Diesel 149 Engines (8V149, 12V149, 16V149):

Blower For Detroit Diesel 12V149

Explanation of how the Series 149’s two-cycle process enables powerful combustion in fewer strokes.

-

Compression and Power Stroke:

Description of the intake, compression, power, and exhaust cycle.

-

Airflow and Scavenging Process:

How the blower aids in expelling exhaust gases and filling cylinders with fresh air.

-

-

Key Components in Combustion For Detroit Diesel 149 Engines (8V149, 12V149, 16V149):

- Blower:

Role in air intake and maintaining cylinder pressure.

- Exhaust Valves:

Detroit Diesel 149 Series Valve Kits (8V149, 12V149, 16V149)

Function in releasing exhaust gases and preparing the engine for the next intake.

- Fuel Injectors:

Importance in delivering fuel at the right pressure and timing.

- Blower:

-

Performance Benefits of the Two-Cycle Design For Detroit Diesel 149 Engines (8V149, 12V149, 16V149)

Why the two-stroke process is beneficial for heavy-duty applications, particularly in demanding settings like marine and industrial environments.

-

-

General Safety and Maintenance Guidelines For Detroit Diesel 149 Series Engines (8V149, 12V149, 16V49)

-

Personal Safety:

- Protective Gear:

Importance of eye protection, gloves, and other safety equipment.

- Cautions with Moving Parts:

Ensuring engine is off before performing tasks near pulleys, belts, and fans.

- Chemical Handling:

Proper ventilation, handling of solvents, and avoiding hazardous chemicals like carbon tetrachloride.

- Protective Gear:

-

Engine Safety:

- Battery Disconnect:

Precautions to avoid accidental starting.

- Proper Lifting Techniques:

Securing heavy components correctly and using engine lifter brackets only as recommended.

- Battery Disconnect:

-

Workspace Setup:

Using a toolbox can keep your tools stored in an organized manner.

- Clean Workspace:

Importance of a clean, organized area to prevent contamination of sensitive engine components.

- Tool Preparation:

Recommendations for keeping tools and equipment in designated areas for quick access.

- Clean Workspace:

-

-

Basic Engine Components and Their Functions For Detroit Diesel 149 Series Engines (8V149, 12V149, 16V49)

-

Cylinder Block:

- Structure and Role:

Explanation of the cylinder block as the engine’s main frame, supporting components.

- Maintenance Tips:

Checking for cracks, wear on bearing caps, and cylinder block inspections.

- Cleaning and Testing:

Using solvent baths, steam cleaning, and pressure testing to detect leaks.

- Structure and Role:

-

Cylinder Head:

- Key Functions:

Houses exhaust valves, fuel injectors, and cooling systems; how these interact.

- Common Issues:

Tips for addressing common wear, maintaining valve clearances, and replacing damaged cylinder heads.

- Key Functions:

-

Fuel System:

- Components and Operation:

Overview of the fuel pump, filter, injectors, and manifold.

- Fuel Quality:

Importance of using clean, high-quality fuel to prevent injector clogs.

- Fuel Line Inspections:

Regular checks for leaks or wear in fuel lines to ensure optimal fuel delivery.

- Components and Operation:

-

Cooling System:

- Purpose and Components:

Engine water jacket, centrifugal pump, and importance of consistent water flow.

- Scale and Corrosion:

Preventing buildup and addressing blocked passages for efficient cooling.

- Purpose and Components:

-

Exhaust System:

- Components and Maintenance:

Role of exhaust valves and manifolds, cleaning buildup, and ensuring free airflow.

- Inspection Tips:

Detecting exhaust leaks or valve wear that can impact engine performance.

- Components and Maintenance:

-

-

Key Maintenance Procedures For Detroit Diesel 149 Series Engines (8V149, 12V149, 16V49)

-

Regular Tune-Ups:

- Injector Timing and Valve Clearance:

Procedure for adjusting injectors and valves to maintain smooth operation.

- Inspection for Wear and Tear:

Checking wear on key components like cylinder blocks, heads, and valves.

- Injector Timing and Valve Clearance:

-

Cleaning and Inspecting Parts:

- Safe Cleaning Methods:

Overview of using steam, solvent tanks, and compressed air for thorough cleaning.

- Cleaning Critical Components:

Careful handling of injector tubes, valves, and head gaskets.

- Safe Cleaning Methods:

-

Replacing Worn Parts:

- Signs of Wear:

Recognizing signs of fatigue in parts like springs, gaskets, and liners.

- Procedure for Part Replacement:

Step-by-step guidance on replacing valve springs, cylinder head gaskets, and other commonly worn parts.

- Signs of Wear:

-

-

Troubleshooting Common Issues For Detroit Diesel 149 Series Engines (8V149, 12V149, 16V49)

-

Overheating:

- Causes:

Clogged coolant passages, malfunctioning water pump, or inadequate coolant levels.

- Solutions:

Flushing the cooling system, replacing the water pump, and adding coolant as needed.

- Causes:

-

Compression Leaks:

- Symptoms:

Engine power loss, fuel inefficiency, and signs of exhaust gases escaping.

- Repairs:

Checking head gaskets, replacing damaged gaskets, and resealing cylinder heads.

- Symptoms:

-

Fuel System Issues:

- Injector Problems:

Recognizing clogged injectors or poor fuel delivery.

- Repair Tips:

Cleaning injectors, replacing damaged fuel lines, and ensuring proper fuel pressure.

- Injector Problems:

-

Exhaust and Valve Wear:

- Symptoms:

Poor exhaust flow, engine knocking, or visible damage on valves.

- Solutions:

Replacing worn valves and adjusting valve clearances to improve engine performance.

- Symptoms:

-

-

Preventive Maintenance Schedule For Detroit Diesel 149 Series Engines (8V149, 12V149, 16V49)

-

Daily Checks:

- Oil and Coolant Levels:

Verifying levels before operation and topping off as necessary.

- Visual Inspection: Checking for leaks, visible wear, and unusual sounds.

- Oil and Coolant Levels:

-

Weekly and Monthly Maintenance:

- Filter Replacements:

Changing fuel and oil filters to maintain cleanliness.

- Component Inspections:

Checking air filters, fuel lines, and coolant hoses for wear.

- Filter Replacements:

-

Quarterly and Annual Service:

- Comprehensive Overhaul:

Full inspection and, if necessary, overhaul of major components like the cylinder head and valve springs.

- Record Keeping:

Maintaining a detailed log of maintenance to track component wear and identify recurring issues.

- Comprehensive Overhaul:

-

-

Conclusion For Detroit Diesel 149 Series Engines (8V149, 12V149, 16V49)

- Importance of Regular Maintenance:

Reinforce the value of preventive care and regular servicing to maximize engine life.

- Utilizing Professional Support:

Encourage seeking expert guidance for complex repairs or engine rebuilds.

- Parts and Resource Availability:

Why using Diesel Pro Power parts for your Detroit Diesel 149 Series engine is the best option.

- Importance of Regular Maintenance:

Please follow and like us:

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588