Introduction: What You Need to Know About Cummins 6BTA Sea Water Pumps

For Cummins engines, the sea water pump is an essential marine engine part that is designed to keep your engine from overheating by bringing in sea water to cool the engine. Whether you’re a boat owner or a professional marine mechanic, understanding how to install and maintain Cummins 6BTA sea water pumps is essential for keeping your vessel in top condition. In this article, we’ll explain the basics of a Cummins 6BTA sea water pump installation, as well as provide tips on how to ensure that your pump runs effectively and safely.

Disclaimer: You should always use your OEM engine model service manual while performing routine maintenance.

1. Preparing the Installation (Site and Materials)

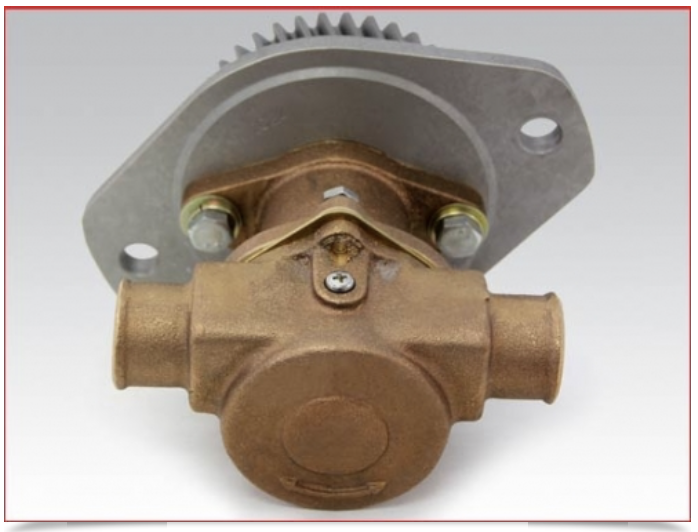

Installing a new sea water pump or replacing an existing one is a simple process. You will need to look at your old sea water pump when selecting a pump for your Cummins 6BTA as there are two styles. As shown below.

- Seawater Pump For Cummins 6BTA Type 1: For this type you will need a mounting gasket.

2.Sea Water Pump For Cummins 6BTA Type 2: For this type you need a mounting gasket, as well as the inlet and outlet port seals.

To install you will use the bolts from your old water pump and you will need a socket wrench.

2. Installing the Sea Water Pump On The Engine Block

Installing a sea water pump on a Cummins engine block is an important task. The process involves removing the old pump, replacing it with the new one, and making sure that all connections are properly secured. It is important to follow the manufacturer’s instructions carefully in order to ensure a successful installation. Additionally, it is also essential to use the right tools and materials for the job in order to avoid any potential problems or damage. With proper preparation and care, installing a sea water pump on a Cummins engine block can be done quickly and safely.

Some basic steps are:

- Shut off the sea water pump inlet valves

- Remove the hoses from the inlet and outlet and drain the sea water pump

- Remove the old water pump & install the new water pump

- Reconnect the inlet and outlet hoses

- Reopen the seawater inlet valves

- Operate the engine and check for leaks

3. Testing the Performance of Your Cummins 6BTA Sea Water Pump System

Testing the performance of your Cummins 6BTA sea Water Pump System is essential for ensuring that your vessel is functioning properly. A sea water pressure test and a sea trial performance test can help you determine if your system is working as expected, and make sure that it will be able to handle the conditions it will be exposed to during its operation.

Raw Water Pump (Marine Water Pump) for Cummins 6BTA Engines

The Cummins 6BTA is a workhorse in the marine engine world, known for its rugged performance, excellent torque, and reliability under prolonged load. To keep that powerplant running at ideal operating temperatures, one component is absolutely critical: the raw water pump. Also referred to as a marine water pump, this unit pulls in seawater to cool the engine via the heat exchanger system.

At Diesel Pro Power, we supply direct-replacement raw water pumps and related marine cooling system components made specifically for the Cummins 6BTA—not generically for other engines, but precision-fit and engineered for the unique demands of this model.

What the Raw Water Pump Does on a Cummins 6BTA

In marine applications, the raw water pump is mounted directly to the front of the 6BTA engine. It’s gear-driven and responsible for drawing seawater through the hull’s intake and circulating it through the heat exchanger. This action cools the engine coolant by transferring heat out into the seawater, which is then discharged overboard. Without a properly functioning marine water pump, your Cummins 6BTA can overheat quickly under load, causing long-term damage.

Key Marine Water Pump Features for 6BTA Applications

Designed for Cummins B-Series Marine Engines Only

All pumps in this catalog are specifically built for the 6BTA engine series. These pumps are not universal, nor are they compatible with land-based or automotive variants of the 6B. The port sizes, gear alignment, and housing structure are aligned to the marine cooling configuration unique to the Cummins 6BTA.

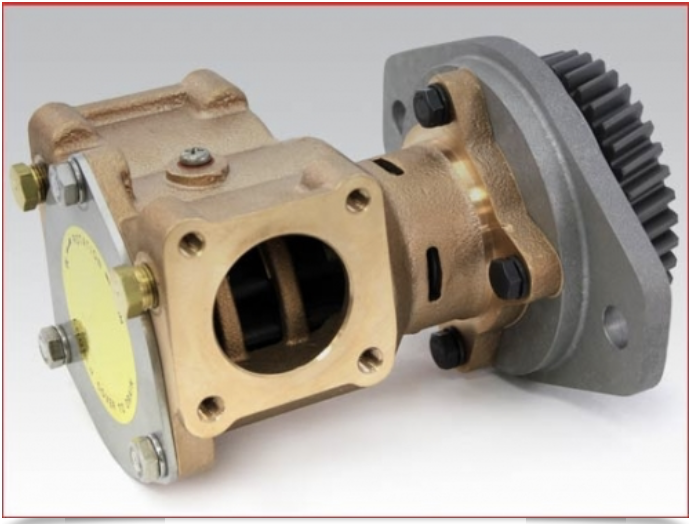

Raw Water Pump (Marine Water Pump) – Bidirectional with Flanged Ports

One of the top-selling options in our catalog is a raw water pump designed for the Cummins 6BTA, engineered with a bidirectional impeller that allows rotation in either direction—clockwise or counterclockwise. This design gives flexibility for installations in different vessel configurations without needing separate pump models.

-

Port Type: 1 3/4″ flange connections allow for easy hose attachment in tight marine engine bays.

-

Gear Shaft Alignment: Features 11° offset mounting holes centered around the drive gear shaft—specific to the 6BTA marine gear housing design.

-

Construction: Built using marine-grade bronze and stainless components to resist corrosion in continuous saltwater operation.

-

Drive System: Fully gear-driven for precise synchronization with the engine’s RPMs and load cycles.

This raw water pump is manufactured for 6BTA installations and fits the pump mounting pattern used in standard marine gear case configurations—no modifications required.

Raw Water Pump (Marine Water Pump) – Gear Driven with 6BTA-Specific Fitment

Another pump we carry for the Cummins 6BTA features the same 1 3/4″ flanged ports and bidirectional operation, but is made with a slightly different body casting to suit alternative mounting clearances in certain marine vessels. Like the first, it is:

-

100% compatible with Cummins 6BTA marine engine cooling systems

-

Bronze-housed with stainless hardware

-

Built to maintain optimal flow rates even under high-load RPM conditions

Both of these marine water pump options are stocked and ready for immediate shipment. Be sure to verify the orientation of your engine’s gear housing and the alignment of bolt holes to ensure a match.

Marine Impeller for Cummins 6BTA Water Pumps

Flexible Neoprene Impeller for Saltwater Applications

Inside the marine water pump is a neoprene impeller—a flexible vane component that rotates within the pump housing to draw and push water. Neoprene is ideal for marine use due to its saltwater resilience and flexibility over time.

For the 6BTA marine water pump, regular inspection and replacement of the impeller are recommended, especially before and after layup seasons. If your pump is not priming properly or your engine is overheating, a degraded or damaged impeller is often the culprit.

Impeller Kit Includes Gaskets, Seals, and O-Rings

Each replacement impeller kit available for the Cummins 6BTA includes:

-

Flexible neoprene impeller

-

Backplate gasket

-

Shaft O-rings or seals

-

Lubricant for dry-install procedures

Routine impeller maintenance extends the life of the pump and helps prevent catastrophic engine overheating.

Impeller Puller for 6BTA Marine Water Pump Service

Removing an old impeller from a marine water pump—especially one that’s been in place for several seasons—can be extremely difficult without the right tool. Diesel Pro Power stocks a marine-grade impeller puller designed to safely extract impellers from Cummins 6BTA raw water pumps without damaging the pump body.

This tool:

-

Works on all standard 6BTA marine water pump impellers

-

Prevents internal scoring from screwdrivers or makeshift tools

-

Speeds up impeller replacement for DIY boat owners and marine service professionals alike

We highly recommend using the proper puller for every impeller change to avoid unintentional damage to the pump housing.

Cooling System Connections and Flow Considerations

The performance of the 6BTA’s raw water pump is influenced by hose size, system resistance, and discharge configuration. Both pump models above are matched to 1 3/4” flanged ports to ensure flow compatibility with OEM heat exchanger and discharge systems.

To maintain proper flow:

-

Use marine-rated hoses that won’t collapse under suction

-

Ensure seawater strainers are clean and free of debris

-

Inspect all hose clamps and fittings during every impeller service

Failure to address these connected systems can result in premature pump wear or restricted cooling capacity.

Installation Notes for Cummins 6BTA Raw Water Pumps

When replacing your raw water pump, pay close attention to the following:

-

Mounting orientation: Ensure gear alignment and offset bolt pattern match the 6BTA marine gear case.

-

Gasket surface prep: Clean all old gasket material from the engine block and apply marine-safe gasket sealant if needed.

-

Shaft alignment: Slide the pump gently into place—never force fit. Shaft misalignment can lead to bearing damage.

-

Rotation check: Confirm engine rotation direction and impeller configuration during installation to ensure proper pump operation.

If you’re unsure about fitment or rotation direction, contact Diesel Pro Power’s team of marine engine specialists. With over 40,000 satisfied customers, we’re experts in Cummins marine engine cooling solutions.

Shop Diesel Pro Power for Cummins 6BTA Marine Cooling Parts

From fully assembled raw water pumps (marine water pumps) to impellers, pullers, gaskets, and seals, Diesel Pro Power is your trusted source for Cummins 6BTA marine cooling components. Our parts are in stock, ready to ship worldwide, and backed by expert support.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588