Metric Conversion Tables

The metric conversion tables are essential for accurately translating measurements across systems, ensuring compatibility and precision in maintenance tasks. For Detroit Diesel Series 60 engines, common conversions include:

- Torque:

1 pound-foot (lb-ft) = 1.35582 newton-meters (Nm)

1 newton-meter (Nm) = 0.737562 pound-feet (lb-ft)

- Length:

1 inch (in) = 25.4 millimeters (mm)

1 millimeter (mm) = 0.0393701 inches (in)

- Pressure:

1 pound per square inch (psi) = 6.89476 kilopascals (kPa)

1 kilopascal (kPa) = 0.145038 psi

These conversions are used throughout various engine diagnostics, repairs, and specifications.

Wear Limits and Tolerances

Parts Catalog for 11.1L Detroit Diesel 60 Series Marine Engine

Parts Catalog for 12.7L Detroit Diesel 60 Series Marine Engine

Parts Catalog for 14L Detroit Diesel 60 Series Marine Engine

Maintaining engine components within specified wear limits and tolerances is critical for optimal performance and longevity. Key wear limits and tolerances for the Detroit Diesel Series 60 engine include:

- Cylinder Liner Diameter:

- New: 130.03 mm (5.118 in)

- Wear limit: 130.15 mm (5.123 in)

- Main Bearing Clearance:

- New: 0.076-0.152 mm (0.003-0.006 in)

- Wear limit: 0.229 mm (0.009 in)

- Connecting Rod Journal Diameter:

- New: 76.20 mm (3.000 in)

- Wear limit: 75.98 mm (2.992 in)

Regular inspection of these components ensures the engine remains within these critical parameters.

Critical Torque Specifications

Torque specifications ensure secure assembly and optimal engine performance. Below is an expanded list of torque values for key components in the Detroit Diesel Series 60 engine.

Cylinder Head Bolts

- Torque: 149-169 Nm (110-125 lb-ft)

- Final Tightening: Additional 90° rotation

Main Bearing Cap Bolts

- Torque: 271-298 Nm (200-220 lb-ft)

Connecting Rod Bolts

- Torque: 108-122 Nm (80-90 lb-ft)

Flywheel Bolts

- Torque: 298-339 Nm (220-250 lb-ft)

- Use thread sealant to prevent oil leakage.

Crankshaft Pulley Bolt

- Torque: 338-364 Nm (250-270 lb-ft)

- Ensure proper alignment of the pulley and crankshaft keyway.

Camshaft Bearing Cap Bolts

- Torque: 20-24 Nm (15-18 lb-ft)

- Sequence tightening evenly to avoid distortion.

Rocker Arm Shaft Bolts

- Torque: 57-67 Nm (42-49 lb-ft)

Valve Cover Bolts

- Torque: 10-12 Nm (7-9 lb-ft)

- Ensure gasket integrity for oil sealing.

Oil Pan Bolts

- Torque: 24-30 Nm (18-22 lb-ft)

Timing Gear Bolts

- Torque: 95-110 Nm (70-81 lb-ft)

- Confirm proper alignment during installation.

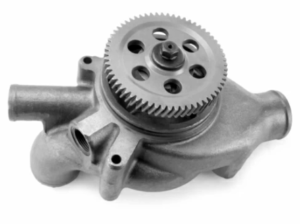

Water Pump Bolts

- Torque: 30-38 Nm (22-28 lb-ft)

Turbocharger Mounting Bolts

- Torque: 41-47 Nm (30-35 lb-ft)

- Recheck after initial operation to ensure no loosening.

Exhaust Manifold Bolts

- Torque: 32-41 Nm (24-30 lb-ft)

- Tighten in sequence to prevent warping.

Engine Mount Bolts

- Torque: 204-217 Nm (150-160 lb-ft)

Oil Filter Adapter Bolts

- Torque: 58-73 Nm (43-54 lb-ft)

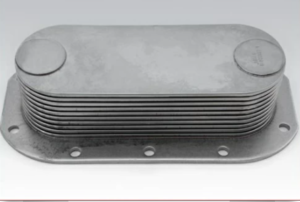

Oil Cooler Housing Bolts

- Torque: 30-38 Nm (22-28 lb-ft)

Accessory Drive Bolts

- Torque: 45-50 Nm (33-37 lb-ft)

EGR Valve Bolts

- Torque: 20-25 Nm (15-18 lb-ft)

Injection Pump Bolts

- Torque: 41-54 Nm (30-40 lb-ft)

Best Practices for Torque Application

- Clean Threads: Ensure all bolt threads and mating surfaces are clean and free of debris or oil unless thread sealant or lubricant is specified.

- Use a Calibrated Torque Wrench: Avoid guessing; improper torque application can lead to leaks, damage, or failure.

- Follow the Correct Sequence: Tighten bolts in the specified pattern, especially for components like cylinder heads and manifolds, to prevent distortion or uneven clamping.

FAQs

- Why is torque specification critical?

Proper torque ensures components are securely fastened without causing damage or warping.

- Can I reuse bolts after disassembly?

Some bolts, like torque-to-yield bolts, are single-use and must be replaced. Always check the specifications for the part being assembled.

- What should I do if I notice bolt loosening during operation?

Re-torque the bolts to the specified value. If loosening persists, inspect for damaged threads or improper installation.

General FAQs

1. What is the purpose of the Detroit Diesel Series 60 Workshop Manual?

The manual provides comprehensive instructions for operation, adjustment, preventive maintenance, repair, and complete overhaul of Detroit Diesel Series 60 engines. It is essential for mechanics and operators to ensure the proper functioning and longevity of these engines.

FAQs on Metric Conversion Tables and Specifications

2. How do I convert torque values from pound-feet to newton-meters?

To convert pound-feet (lb-ft) to newton-meters (Nm), multiply the value by 1.35582.

For example:

- 100 lb-ft × 1.35582 = 135.582 Nm.

3. Why are specific tolerances and wear limits important for engine components?

Adhering to wear limits and tolerances ensures the engine operates efficiently, prevents premature failure, and maintains optimal performance. Exceeding these limits may result in severe damage.

4. Can I use standard tools to measure tolerances?

Precision tools like micrometers, dial indicators, and bore gauges are recommended for accurate measurements. Improper tools can lead to errors and potential engine damage.

FAQs on Torque Specifications

5. What happens if I over-torque or under-torque a bolt?

- Over-torque: This may stretch or weaken the bolt, leading to potential failure under stress.

- Under-torque: This can cause loosening during operation, resulting in leaks or misalignment of components.

6. How do I ensure proper torque application?

- Use a calibrated torque wrench.

- Follow the tightening sequence specified in the manual.

- Apply thread sealant or lubricant only when recommended.

FAQs on Engine Components

7. What is the function of the oil pump in the lubrication system?

The oil pump circulates oil under pressure to critical components such as bearings, camshafts, and pistons. This prevents friction, overheating, and wear.

8. How can I check the gear lash on the oil pump drive gear?

Use a dial indicator to measure the clearance between the oil pump drive gear and the crankshaft gear. Acceptable gear lash ranges from 0.051-0.229 mm (0.002-0.009 in).

9. What are the symptoms of a failing cylinder liner?

- Excessive blow-by or smoke.

- Coolant contamination in the oil or vice versa.

- Loss of compression or power.

- Visible scoring or cracks during inspection.

FAQs on Fuel and Lubrication Systems

10. How often should I replace the oil filters?

- Truck and Parlor Coach Applications: Every 24,000 km (15,000 miles).

- Transit Coach Applications: Every 9,600 km (6,000 miles).

Replace the filters during every oil change or sooner if contamination is suspected.

11. What type of oil should I use for Series 60 engines?

Refer to API specifications and viscosity grades recommended for your specific operating conditions. Use high-quality heavy-duty oils for optimal performance.

12. Why is the oil cooler necessary?

The oil cooler maintains the oil at an appropriate temperature. It prevents oil from becoming too thick (when cold) or too thin (when overheated), ensuring adequate lubrication and protection.

FAQs on Cooling Systems

13. How do I know if my oil cooler is leaking?

Perform a pressure test by immersing the cooler in water while applying 75-100 psi of air pressure. Look for bubbles indicating leaks.

14. How do I clean the oil cooler?

- Use an approved solvent, such as Tech Solv 340, to flush internal passages.

- For external cleaning, immerse in a muriatic acid solution and flush thoroughly with hot water.

15. Can I bypass the oil cooler if it fails?

While a bypass is possible, it is not recommended for long-term use as it may lead to overheating and inadequate lubrication.

FAQs on Preventive Maintenance

16. What is the recommended preventive maintenance schedule for Series 60 engines?

- Daily: Inspect fluid levels, check for leaks, and assess for unusual noises.

- Every 6,000-24,000 km (4,000-15,000 miles): Perform oil and filter changes, and inspect wear-prone components like belts and hoses.

- Annually or during overhauls: Conduct a full inspection of the engine, including tolerances, wear limits, and system functionality.

17. What tools are necessary for effective maintenance?

- Torque wrench for precise tightening.

- Precision gauges (micrometers, dial indicators, etc.) for measurements.

- Cleaning solvents and appropriate personal protective equipment (PPE).

FAQs on Troubleshooting

18. What should I do if the engine fails to start?

- Check the fuel system for proper delivery and injector operation.

- Ensure the battery is fully charged and connections are secure.

- Inspect the air intake system for obstructions.

19. How do I diagnose excessive exhaust smoke?

- White Smoke: Indicates coolant leakage into the combustion chamber.

- Black Smoke: Points to excessive fuel delivery or insufficient air intake.

- Blue Smoke: Suggests oil burning due to worn piston rings or valve seals.

20. What are common causes of overheating?

- Insufficient coolant levels or leaks.

- Malfunctioning thermostats or water pumps.

- Blocked oil or coolant passages in the radiator or engine block.

Additional Resources

- For Parts: Diesel Pro Power offers premium aftermarket components for Series 60 engines, ensuring high-quality replacements.

- Troubleshooting Guides: Refer to the respective sections in the manual for detailed diagnostics and repair processes.

- Customer Support: Visit Diesel Pro Power’s Help Center for expert assistance.

Parts Catalog for 11.1L Detroit Diesel 60 Series Marine Engine

Parts Catalog for 12.7L Detroit Diesel 60 Series Marine Engine

Parts Catalog for 14L Detroit Diesel 60 Series Marine Engine

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588