Introduction

The Cummins C Series (6C, 6CT, 6CTA) engines are known for their durability, efficiency, and versatility in marine, industrial, construction, and agricultural applications. To ensure long-term engine health, following a structured maintenance schedule, investing in high-quality aftermarket parts, and practicing proactive maintenance is essential. Proper engine care not only prevents costly repairs but also maximizes fuel efficiency and lifespan.

This guide covers the recommended maintenance intervals, key preventive measures, and the benefits of using premium aftermarket parts.

Parts Catalog for Cummins 6C Marine Engine

Parts Catalog for Cummins 6CT Marine Engine

Parts Catalog for Cummins 6CTA Marine Engine

Maintenance Schedules and Procedures

A well-maintained Cummins 6C, 6CT, or 6CTA engine can last well beyond its expected lifespan. Below is a recommended maintenance schedule that ensures optimal performance.

Daily Maintenance Checks

- Oil Level Inspection – Maintain oil levels within the recommended range. Low oil levels can lead to engine wear and overheating.

- Coolant Level Check – Verify proper coolant levels to prevent overheating and engine damage.

- Visual Inspection for Leaks – Look for signs of fuel, oil, or coolant leaks around hoses, fittings, and seals.

- Exhaust Smoke Monitoring – Unusual smoke colors (black, white, or blue) can indicate fuel system or combustion issues.

- Noise and Vibration Check – Unusual engine sounds could be a sign of loose components, worn bearings, or misfiring cylinders.

Every 250 Hours (or Monthly)

- Change Engine Oil and Filter – Prevent sludge buildup and premature wear.

- Inspect Air Filter – A dirty filter reduces air intake, causing reduced efficiency.

- Check Belt and Hose Condition – Cracked or frayed belts can fail unexpectedly.

- Battery Voltage Test – Ensures proper starting power and charging system function.

Every 500 Hours (or Every 3-6 Months)

- Replace Fuel Filter – Keeps contaminants from reaching the injectors.

- Flush and Refill Cooling System (If Necessary) – Prevents corrosion and scale buildup.

- Inspect Turbocharger for Wear or Damage – A failing turbo can lead to power loss and increased fuel consumption.

- Valve Lash Adjustment – Ensures correct valve timing and fuel combustion.

Every 1,000 Hours (or Annually)

- Injector Inspection and Cleaning – Worn injectors can cause power loss and excessive fuel consumption.

- Cooling System Pressure Test – Identifies leaks or weak hoses.

- Inspect Exhaust Manifold and Gaskets – A leak can reduce efficiency and cause engine overheating.

- Check Alternator and Starter Motor – Ensures reliable engine operation.

Every 2,000 Hours (or Every 2-3 Years)

- Replace Coolant – Over time, coolant loses its protective properties.

- Inspect and Replace Turbocharger (If Needed) – Ensures optimal air compression.

- Perform Compression Test – Assesses overall engine health.

- Inspect Main Bearings and Rod Bearings – Prevents catastrophic failure in high-usage applications.

Regular maintenance prevents expensive repairs and keeps the Cummins 6C, 6CT, and 6CTA engines running efficiently.

The Value of Using Premium Aftermarket Parts

When replacing parts on a Cummins 6C, 6CT, or 6CTA engine, choosing premium aftermarket parts can save money while maintaining OEM-level reliability.

Why Choose High-Quality Aftermarket Parts?

- Cost Savings Without Sacrificing Quality

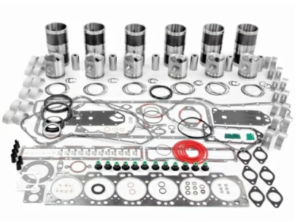

Rebuild Kit for Cummins 6C, 6CT, 6CTA – 1 piece piston

- High-quality aftermarket parts typically cost 20-50% less than OEM parts.

- Affordable pricing makes it easier to maintain regular servicing.

- Performance Equal to or Better Than OEM

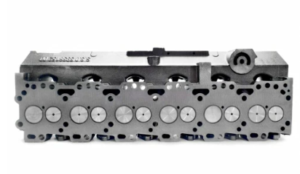

Cylinder Head for Cummins 6C, 6CT, 6CTA 8.3

- Many aftermarket components meet or exceed OEM specifications.

- Advanced metallurgy and precision engineering ensure superior performance.

- Readily Available with No Long Wait Times

Connecting rod for Cummins 6C, 6CT and 6CTA engines

- OEM parts may have long lead times, causing delays.

- Aftermarket parts are widely available, minimizing downtime.

- Enhanced Materials and Upgrades

New piston kit, for use with Cummins 6C 8.3, 6CT 8.3 and 6CTA 8.3 engines.

- Coated pistons and reinforced bearings provide superior wear resistance.

- Upgraded turbochargers and fuel injectors improve engine performance.

Recommended Aftermarket Parts for Cummins C Series

- Pistons and Rings – Enhanced heat resistance and durability.

- Bearings and Gaskets – Precision-engineered materials prevent premature wear.

- Fuel Injectors – Ensure consistent fuel delivery and improved efficiency.

- Turbochargers – Optimize boost pressure for better engine power.

- Cylinder Heads – Reinforced for extended service life.

- Overhaul Kits– Rebuild your engine to restore the performance.

Investing in premium aftermarket parts is a cost-effective way to ensure reliable long-term engine health.

Proactive Maintenance to Prevent Costly Repairs

Being proactive rather than reactive is the key to preventing expensive engine failures.

Common Preventable Issues

- Overheating and Cooling System Failures

New upper gasket set, for Cummins C, ISC, ISL engines

- Regular coolant flushes and radiator inspections prevent head gasket failure and cracked cylinder heads.

- Overheating can lead to complete engine failure.

- Fuel System Contamination

Cummins fuel filter, for Cummins 6C8.3, 6CT8.3, 6CTA8.3, ISC, QSC, L10, ISL, QSL engines.

- Dirty fuel filters reduce engine efficiency and damage fuel injectors.

- Water in the fuel system causes injector corrosion.

- Lubrication System Failures

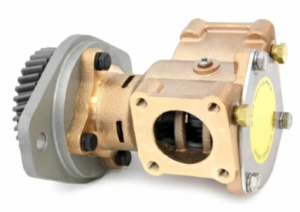

New oil pump, for use in Cummins 6C, 6CT and 6CTA engines.

- Running low on oil or using low-quality oil results in bearing failure and engine seizure.

- Using high-quality synthetic or semi-synthetic oil extends engine life.

- Turbocharger Wear and Damage

- Clogged air filters or insufficient oil lubrication can prematurely wear turbo bearings.

- Replacing damaged or worn-out turbos restores engine power and efficiency.

- Piston and Valve Damage

New intake valve, for Cummins 6C8.3, 6CT8.3 and 6CTA8.3 engines.

- Neglecting valve lash adjustments causes misfires, power loss, and increased emissions.

- Using subpar piston materials can lead to piston cracking and oil burning.

The Financial Impact of Preventative Maintenance

- Example 1: Turbocharger Failure

Reactive Repair: Replacing a failed turbo costs $3,000+.

Proactive Maintenance: Regular oil changes and turbo inspections extend turbo life, saving thousands.

- Example 2: Cooling System Neglect

Reactive Repair: A cracked cylinder head due to overheating costs $5,000+.

Proactive Maintenance: Flushing coolant and replacing old hoses prevents overheating and catastrophic failures.

- Example 3: Fuel Injector Failure

Reactive Repair: Clogged or failing injectors can reduce fuel efficiency and damage pistons.

Proactive Maintenance: Replacing fuel filters on schedule keeps the fuel system clean.

Taking a preventative maintenance approach saves thousands in unexpected repairs while maximizing engine uptime.

Final Thoughts

To ensure long-term reliability for Cummins 6C, 6CT, and 6CTA engines, follow a structured maintenance schedule, invest in high-quality aftermarket parts, and adopt a proactive maintenance approach.

For premium Cummins 6C, 6CT, and 6CTA aftermarket parts, visit Diesel Pro Power. We offer rebuild kits, injectors, turbochargers, cooling system components, and more—ensuring your engine stays reliable and efficientfor years to come.

Parts Catalog for Cummins 6C Marine Engine

Parts Catalog for Cummins 6CT Marine Engine

Parts Catalog for Cummins 6CTA Marine Engine

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588