The Cummins N14 Overhaul Kit

Diesel Pro Power, Inc. Cummins N14 overhaul kits are a great way to restore a Cummins N14 engine to its original state. These kits come with all the necessary parts and components to do a complete overhaul of the engine and ensure its continued performance. The Cummins N14 engine is a popular choice for a variety of applications and is known for its durability and reliability. With the right parts and a careful overhaul, the Cummins N14engine can last for many years to come. In this article, we will discuss the components included in a Diesel Pro Power, Inc. Cummins N14 overhaul kit and how they can help to restore your engine to its original state.

Identifying What Cummins N14 Overhaul Kit You Need

Use your engines CPL number to identify the correct overhaul kit for your engine.

Parts Included in a Cummins N14Overhaul Kit

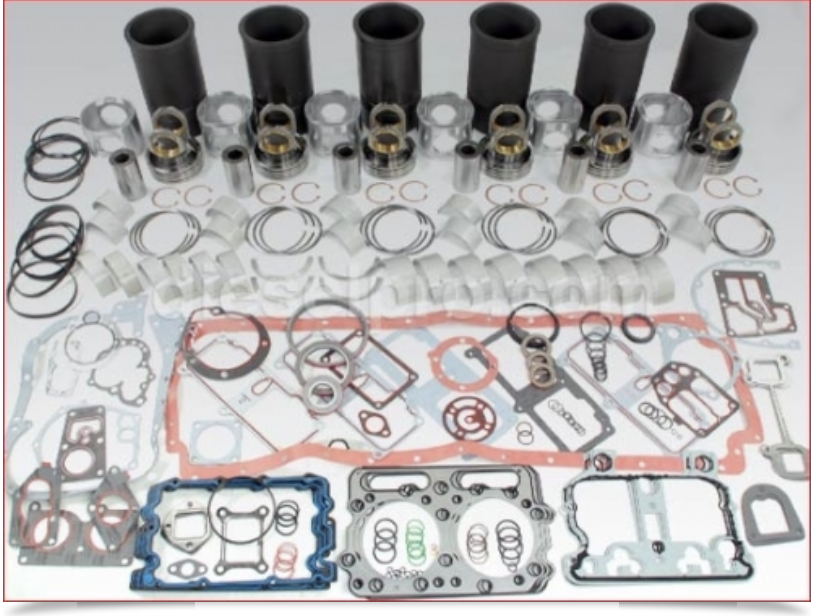

Engine Overhual Kit for Cummins N14 Marine Engine

A Diesel Pro Power, Inc. Cummins N14overhaul kit typically contains all the parts and components necessary to complete a full rebuild of the engine. The kit typically includes pistons, liners, piston rings, piston pin retainers, piston pins, crankshaft bearings, connecting rod bearings, and upper and lower gasket sets..

A breakdown of the components is as follows:

Pistons – 6 units

Liners – 6 units

Piston Pins – 6 units

Piston Pin Retainers – 12 units

Piston Rings Sets – 6 units

Crankshaft Bearings Set – 1 unit

Connecting Rod Bearing Set – 6 units

Upper Gasket Kit – 1 unit

Lower Gasket Kit – 1 unit

Benefits of a Cummins N14 Overhaul Kit

The primary benefit of a Diesel Pro Power, Inc. Cummins N14 overhaul kit provides a complete rebuild of the engine in one package. It eliminates the need to purchase individual components and parts, which can be time-consuming and expensive. Additionally, the kit includes parts and components that have been tested and certified to meet the highest standards of quality, ensuring that your engine is getting the best possible parts and components. Additionally, our kits come with a one year warranty, which provides additional peace of mind. Generally, the cost of the kit is lower than the cost of buying all the individual parts and components separately.

Get Your Diesel Pro Power, Inc. N14 Overhaul Kit

Diesel Pro Power, Inc. Cummins N14 overhaul kits are a great way to restore an aging Cummins N14 engine to its original condition. The kit typically contains all the parts and components necessary to complete a full rebuild of the engine, including pistons,liners, piston rings, piston pin retainers, piston pins, crankshaft bearings, connecting rod bearings, and upper and lower gasket sets. Additionally, the cost of the kit is usually lower than the cost of buying all the individual parts and components separately. If you are looking for a way to restore your Cummins N14 engine to its original state, a Diesel Pro Power, Inc. Cummins N14 overhaul kit is the way to go.

10 Reasons Your Cummins N14 May Need a Rebuild

The Cummins N14 is one of the most trusted heavy-duty diesel engines ever built, powering countless on-highway trucks, marine vessels, and industrial machines. Known for its long service life and reliability, the N14 can run for hundreds of thousands of miles — but no diesel lasts forever. Eventually, wear, heat, and high mileage can take their toll.

If you’re wondering whether it’s time to overhaul your N14 and invest in a rebuild kit, here are the ten most common signs that point toward a major refresh. Understanding these symptoms will help you plan ahead, avoid catastrophic damage, and get the right parts the first time.

1. Excessive Oil Consumption

If your N14 is going through oil faster than normal, it often means:

-

Worn piston rings letting oil slip into the combustion chamber.

-

Cylinder liner wear reducing proper sealing.

-

Valve stem seals hardening or cracking with age.

Excessive oil consumption can damage your turbo, foul injectors, and increase emissions. A complete rebuild kit — with new pistons, liners, rings, and gaskets — restores proper oil control and compression.

2. Noticeable Power Loss or Poor Fuel Efficiency

When an N14 loses its original pulling power, it’s often due to:

-

Cylinder and ring wear causing low compression.

-

Valve seat erosion reducing airflow.

-

Head gasket leakage between cylinders.

A rebuild refreshes these high-wear parts and can dramatically restore lost horsepower and torque — especially important for trucks hauling heavy loads.

3. Coolant Contamination or Chronic Leaks

If you’re seeing milky oil, coolant loss with no visible leaks, or white exhaust smoke, your engine may have:

-

A blown head gasket.

-

Cracked cylinder head.

-

Liner pitting letting coolant seep into the cylinders.

Rebuilding lets you replace gaskets, check or machine the head, and renew the cooling system to keep the N14 from overheating again.

4. Excessive Blow-By

Blow-by — combustion gases escaping into the crankcase — is one of the clearest indicators of worn rings and liners. You might notice:

-

Smoke or fumes venting from the breather.

-

Rising crankcase pressure.

-

Persistent oil leaks.

A proper rebuild kit includes new liners, pistons, and rings to restore sealing and reduce crankcase pressure.

5. Abnormal Exhaust Smoke

-

Blue smoke: Oil is burning due to worn rings or valve seals.

-

White smoke: Coolant is entering the combustion chamber.

-

Black smoke: Poor fuel combustion, often from low compression or injector issues.

If simple fixes (like injector service or turbo replacement) don’t solve it, a rebuild is usually the only way to stop excessive smoke.

6. Overheating Under Load

The N14 can handle hard work, but chronic overheating damages the head, liners, and pistons. Common causes:

-

Failing water pump or radiator.

-

Blocked cooling passages from scale or debris.

-

Warped head after repeated heat cycles.

Once overheating becomes a pattern, rebuilding is safer than risking catastrophic cracking or gasket failure.

7. High Mileage or Operating Hours

Even well-maintained engines have a service life. Typical rebuild intervals:

-

On-highway trucks: 750,000 to 1,200,000 miles depending on load and duty cycle.

-

Marine/industrial engines: 20,000–30,000 operating hours.

Planning a rebuild proactively — before failure — minimizes downtime and can save thousands in emergency repairs.

8. Ongoing Fuel System Problems

Frequent injector replacements, hard starts, and uneven idle may point to deeper wear:

-

Worn camshaft lobes driving the injectors.

-

Timing issues from worn internal components.

-

Fuel contamination damage over the years.

A rebuild lets you reset the fuel system while renewing the core engine, ensuring consistent combustion and power.

9. Turbocharger Damage Linked to Engine Wear

If you’ve already replaced your turbo and it failed again, the root cause might be inside the engine:

-

Oil contamination or high oil consumption damaging bearings.

-

Metal particles from internal wear reaching the turbo.

-

High exhaust temps from poor combustion overheating the turbine.

A rebuild restores proper oil control and combustion balance, helping a new turbo last.

10. Sudden Internal Failure

Some N14 failures happen fast and leave no choice but a rebuild:

-

Spun main or rod bearings from oil starvation.

-

Dropped valve hitting the piston.

-

Broken piston skirt scattering debris throughout the engine.

When major internal damage occurs, an out-of-frame rebuild or full remanufacture is the only way forward.

Why a Quality Rebuild Kit Matters

A rebuild is a major investment, but choosing the right Cummins N14 rebuild kit can save time and ensure a reliable result. The best kits include:

-

New liners, pistons, and rings to restore compression and oil control.

-

Main and rod bearings to protect the crankshaft.

-

Complete gasket sets for a leak-free seal.

-

Top-quality seals and o-rings compatible with modern fluids.

Using a trusted kit keeps your overhaul straightforward and ensures your N14 performs like new for thousands more miles.

Planning Your N14 Overhaul

-

Decide between in-frame vs. out-of-frame:

-

In-frame is less invasive and works if your block and crank are healthy.

-

Out-of-frame includes full machining and is best for high-mileage or damaged engines.

-

-

Inspect the cylinder head:

Pressure test, resurface, and install new valves/seats if needed. -

Choose high-quality components:

Diesel Pro Power supplies premium N14 rebuild kits trusted by fleets and independent operators worldwide. -

Plan for downtime:

Doing a scheduled rebuild can be cheaper and faster than an emergency overhaul after failure.

Keeping Your N14 Running Strong

Preventive maintenance can delay a rebuild and extend engine life:

-

Regular oil analysis to catch early wear.

-

Coolant checks and flushes to prevent liner pitting.

-

Clean fuel supply with timely filter changes.

-

Avoiding excessive idling to reduce cylinder glazing.

Even with perfect care, however, the time will come when a rebuild is the smartest move — especially if you plan to keep the truck, vessel, or equipment for years to come.

Bottom Line

The Cummins N14 is legendary, but every engine wears out eventually. If you’re seeing oil consumption, power loss, overheating, or catastrophic failure, it’s likely time to rebuild. A high-quality rebuild kit will give your N14 a second life, restore performance, and minimize future breakdowns.

When it’s time to overhaul, Diesel Pro Power offers premium Cummins N14 rebuild kits backed by 40,000+ satisfied customers worldwide. Each kit is designed for reliability and straightforward installation — so you can get back on the road or back to work with confidence.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588