July 16, 2025

Why Diesel Pro Power is the Only True Source for Detroit Diesel 12V149 Overhaul Kits — In Stock and Ready to Ship

The Detroit Diesel 12V149: A Legend of Industrial Power

Key Specs That Made History

Where You’ll Find Them Today

Why the 12V149 is So Difficult to Support

These Engines are Rare and Out of Regular Production

Turbo and Non-Turbo Differences Add Complexity

Why Diesel Pro Power is Different: The World’s True Stocking Source

Why This Matters for Your Operation

What’s Inside Our Detroit Diesel 12V149 Overhaul Kits

Premium Components Include:

Turbo vs. Non-Turbo: We Stock Both

Why Most Companies Can’t — or Won’t — Stock These Kits

Enormous Inventory Risk

Complex Global Logistics

The Diesel Pro Power Difference: Why We’re Trusted Worldwide

Actual In-Stock Inventory

Fast Shipping, Global Reach

Unmatched Technical Support

Avoid the Disaster of Mismatched or Delayed Kits

Serving the World’s Most Demanding Industries

A Few Words on Why We Only Stock Premium Kits

Conclusion: If You Operate a Detroit Diesel 12V149, You Can’t Afford to Wait

Other Parts That We Carry For Detroit Diesel 12V149

Additional Resources For The Detroit Diesel 12V149

Read More

July 16, 2025

Understanding Marine Diesel Piston Compression: What It Means for Cummins, Detroit Diesel, and Caterpillar Engines

What Is Piston Compression in a Marine Diesel Engine?

Why Compression Matters in Marine Diesel Engines

Power and Efficiency

Cold Starting Reliability

Emission Control and Smoke

Engine Longevity

How Compression Works in Cummins, Detroit Diesel, and Caterpillar Engines

Cummins Marine Engines

Detroit Diesel Marine Engines

Caterpillar Marine Engines

What Causes Compression Loss in Marine Diesels?

Worn or Broken Piston Rings

Scored or Glazed Cylinder Walls

Valve Leakage

Head Gasket Failure

Cracked Heads or Blocks

Signs Your Engine Has Low Compression

How to Test Marine Diesel Compression

Fixing Low Compression: Options and Repairs

Replacing Rings and Liners

Valve Work

Head Gaskets or Cracks

How to Maintain Strong Compression

Why Compression Needs Are Different in Marine Engines vs. Trucks

Conclusion: Keep Compression Strong, Keep Your Vessel Reliable

Read More

July 16, 2025

1. Understanding the Role of a Cylinder Head in Your Cummins Marine Engine

2. When a Rebuild Might Make Sense

2.1 Minimal Damage and Low Hours

2.2 Temporary Fleet Strategy

2.3 Immediate Local Shop Turnaround

3. The Risks and Drawbacks of Rebuilding Cylinder Heads

3.1 Hidden Hairline Cracks

3.2 Warped Deck Surfaces

3.3 Inferior Local Machining

3.4 Downtime Costs More Than Parts

4. Why Replacing With a New Cylinder Head is Often the Best Option

4.1 Zero Hours and Zero Surprises

4.2 Exact OEM-Level Design

4.3 Faster Turnaround

4.4 Peace of Mind Warranty

5. Spotlight on Cummins Marine Cylinder Head Applications

5.1 Cummins 4B

5.2 Cummins 4BT

5.3 Cummins 4BTA

5.4 Cummins 6B

5.5 Cummins 6BT

5.6 Cummins 6BTA

5.7 Cummins ISB

5.8 Cummins QSB

5.9 Cummins 6C

5.10 Cummins 6CT

5.11 Cummins 6CTA

5.12 Cummins ISC

5.13 Cummins QSC

5.14 Cummins L10

5.15 Cummins ISL

5.16 Cummins QSL

5.17 Cummins M11

5.18 Cummins ISM

5.19 Cummins QSM

5.20 Cummins NH855

5.21 Cummins NT855

5.22 Cummins N14

5.23 Cummins ISX

5.24 Cummins QSX

5.25 Cummins KTA19

5.26 Cummins KTA38

5.27 Cummins KTA50

5.28 Cummins QSK19

6. Why Choose Diesel Pro Power for Your New Cylinder Head

6.1 Shipped From Our Warehouse Within 24 Hours

6.2 Premium Aftermarket Quality

6.3 Serving Global Marine Operators

6.4 Expert Selection Assistance

8. Cost Comparisons: Rebuilding vs. New Cylinder Head

Typical Rebuild Costs

Typical New Head Costs

9. FAQs About Marine Cylinder Heads

10. Conclusion: Why New Cylinder Heads from Diesel Pro Power are the Smart Bet

Ready to Order or Get Expert Guidance?

Read More

July 16, 2025

Cummins Parts Near Me: Get Quality Parts Shipped Fast From Diesel Pro Power

1. Why “Cummins Parts Near Me” Often Means Fast Nationwide Shipping

2. Specialized In Getting Cummins Marine Parts Near You Fast

3. Cylinder Heads For Cummins Engines: Precision Where It Matters Most

4. Overhaul Kits For Cummins Engines: Complete Solutions In One Shipment

5. Injectors For Cummins Engines: The Heartbeat Of Diesel Efficiency

6. Turbos For Cummins Engines: Reliable Boost For Marine & Industrial Power

7. Oil Pumps For Cummins Engines: Protecting The Lifeblood Of Your Diesel

8. Freshwater Pumps For Cummins Engines: Keeping Cool In Harsh Environments

9. Gaskets For Cummins Engines: The Unsung Heroes Of Longevity

10. Fuel Pumps For Cummins Engines: Precision In Every Gallon Delivered

11. Oil Filters & Fuel Filters For Cummins Engines: Protection Starts Here

12. Why Diesel Pro Power Is Your Best Answer To “Cummins Parts Near Me”

13. How To Get Your Cummins Parts Delivered Quickly

14. Ready To Get Started?

Final Word

Read More

May 9, 2025

1. Marine Applications of the Cummins 6.7L Engine

1. Recreational Yachts and Cruisers

2. Commercial Fishing Vessels

3. Passenger Ferries and Charter Boats

4. Pilot Boats and Patrol Craft

5. Tugboats and Support Vessels

2. Top Causes of Overheating in Marine Cummins 6.7L Engines

1. Restricted Raw Water Flow

2. Clogged or Fouled Heat Exchangers

3. Failing Thermostat

4. Low Coolant or Improper Coolant Mix

5. Raw Water Pump Failure

6. Clogged Keel Cooler (For Vessels Without Heat Exchangers)

7. Faulty Temperature Sensor or ECU Misreading

8. EGR Cooler Failure (in Emissions-Compliant Models)

9. Internal Corrosion from Improper Coolant or Storage

10. Overloading and Continuous High RPM Operation

3. Maintenance Best Practices for Marine Cummins 6.7L Engines

4. Recommended Parts from Diesel Pro Power

Conclusion: Keep Your QSB6.7 Cool and On the Water

Read More

April 28, 2025

Cummins 6CTA: Application Commercial Fishing Vessels

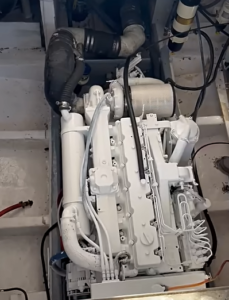

Introduction – Featuring Imperial Diesel Service, LLC Installation

Technical Overview of the Cummins 6CTA for Fishing Vessels

Why the Cummins 6CTA is a Top Choice for Commercial Fishing

Common Fisheries Using the Cummins 6CTA

Bottom Fishing in the Gulf of America (formerly known as the Gulf of Mexico) & Florida Keys

Lobster Fisheries – Maine, Canada, New England, and Florida Keys

Latin America and Caribbean Fisheries

Crab Fisheries – Alaska, Pacific Northwest, Gulf of America

Shrimp Trawling – Gulf of America, South America, Southeast Asia

Tuna Longlining – Pacific, Indian Ocean

Scallop and Clam Dredging – North Atlantic

Gillnetting and Trawling – Coastal and Nearshore

Installation Considerations for Commercial Fishing Vessels

Maintenance and Longevity in Fishing Applications

Aftermarket Support and CPL Cross-Reference

FAQs – Cummins 6CTA in Commercial Fishing

Final Thoughts

Read More

Page 1 of 5912345...102030...»Last »

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588