February 27, 2025

Introduction

Daily Maintenance Operations for Cummins KTA38 and KTA50

Daily Checklist for Cummins KTA38 and KTA50

1. Check Oil Levels and Top Off with the Recommended SAE-Grade Oil

2. Inspect Coolant Levels and Maintain Proper Concentration

3. Look for Leaks in Fuel, Coolant, and Oil Systems

4. Inspect the Air Intake System and Clean Air Filters If Necessary

5. Check Belts and Pulleys for Wear or Misalignment

6. Drain Water Separators to Remove Moisture from the Fuel System

7. Monitor Dashboard Indicators for Abnormal Readings

Conclusion

Key Takeaways:

Read More

February 27, 2025

Introduction

Identifying Your Cummins KTA38 and KTA50 Engine

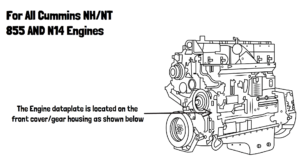

Where to Find the Engine Data Plate

Key Information on the Data Plate

Why Engine Identification is Important

Verifying Engine Identification

General Maintenance Guidelines for Cummins KTA38 and KTA50

1. Lubrication and Oil Maintenance

2. Cooling System Maintenance

3. Fuel System Maintenance

4. Air Intake and Turbocharger Maintenance

5. Valve and Injector Maintenance

6. Fasteners and Torque Specifications

Conclusion

Key Takeaways:

Read More

February 27, 2025

Introduction for Cummins KTA38 and KTA50

Understanding the Cummins KTA38 and KTA50 Engines

Engine Overview

Common Applications

Maintenance Schedule for Cummins KTA38 and KTA50

Daily Maintenance Operations

Weekly Maintenance Operations

Maintenance Every 250 Hours or 6 Months

Maintenance Every 1,500 Hours or 1 Year

Maintenance Every 6,000 Hours or 2 Years

Operational Best Practices for Cummins KTA38 and KTA50

Starting the Engine Properly

Efficient Load Management

Shutdown Procedures

Troubleshooting Common Issues in Cummins KTA38 and KTA50

1. Engine Overheating

2. Loss of Power

3. Excessive Smoke from Exhaust

4. Hard Starting or No Start

Read More

February 27, 2025

Identifying Your Engine for Cummins KTA38 and KTA50

General Maintenance Guidelines for Cummins KTA38 and KTA50

Daily Checklist for Cummins KTA38 and KTA50

Essential Weekly Inspections for Cummins KTA38 and KTA50

250 Hours or 6 Months for Cummins KTA38 and KTA50

1,500 Hours or 1 Year for Cummins KTA38 and KTA50

6,000 Hours or 2 Years for Cummins KTA38 and KTA50

Engine Overheating for Cummins KTA38 and KTA50

Loss of Power for Cummins KTA38 and KTA50

Excessive Black Smoke for Cummins KTA38 and KTA50

Hard Starting or No Start for Cummins KTA38 and KTA50

Final Thoughts on Cummins KTA38 and KTA50 Maintenance

Read More

February 26, 2025

Introduction

A. Electrical System Safety

1. Disconnect the Battery Before Performing Electrical Work

B. Handling Heavy Components Safely

1. Use Proper Lifting Tools for Heavy Components

C. Fuel System Safety

1. Wear Eye Protection When Working Around Pressurized Fuel Lines

D. Cooling System Safety

1. Allow the Engine to Cool Before Opening the Radiator Cap

E. Torque Specifications & Fastener Safety

1. Never Exceed Torque Specifications

F. Fire and Chemical Safety

1. Avoid Open Flames When Working with Flammable Liquids

G. Worksite Safety Best Practices

1. Maintain a Clean and Organized Work Area

2. Wear Proper Personal Protective Equipment (PPE)

Conclusion

Read More

February 26, 2025

Introduction

A. Engine Disassembly

1. Preparation & Safety Measures

2. Remove External Components

3. Cylinder Head & Valve Train Removal

4. Piston & Connecting Rod Removal

5. Camshaft & Crankshaft Removal

B. Cleaning & Inspection

1. Cleaning the Block & Cylinder Head

2. Crack & Warping Inspection

3. Inspect Cylinder Liners & Pistons

4. Connecting Rod & Crankshaft Inspection

C. Engine Reassembly & Torque Specifications

1. Installing the Crankshaft & Bearings

2. Piston & Connecting Rod Installation

3. Camshaft & Timing Gear Installation

4. Cylinder Head & Valve Train Assembly

5. Fuel Injector Installation & Priming the Lubrication System

Final Checks & Engine Startup

1. Pre-Start Inspection

2. Priming the Fuel System

3. Initial Engine Start & Break-In Procedure

Common Issues & Troubleshooting After a Rebuild

1. Engine Won’t Start

2. Low Oil Pressure

3. Overheating Issues

4. Excessive Smoke from Exhaust

Conclusion

Read More

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588