November 5, 2024

How Maintenance Supports Longevity For Detroit Diesel 149 Series Engines (8V149, 12V149, 16V149)

Reliability through Preventive Maintenance

Key Components for Preventive Maintenance

The Value of Scheduled Inspections and Component Replacement

Maintenance Intervals and Best Practices

Daily Checks

Regular Service Intervals (e.g., 300, 600, and 1,000 hours)

Long-Term Overhauls (5,000 hours)

Benefits of Structured Maintenance Intervals

Read More

November 5, 2024

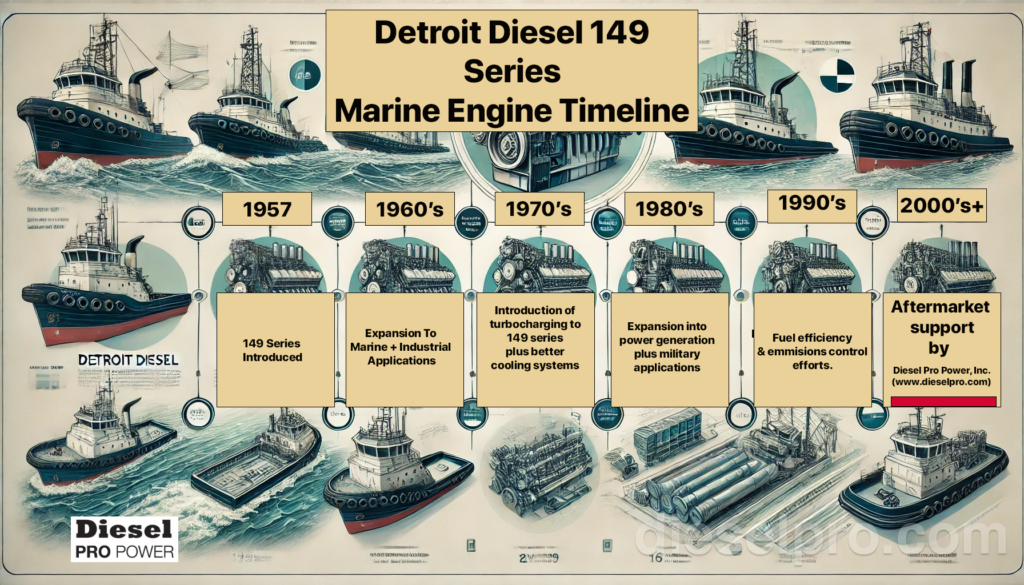

History and Development Of The Detroit Diesel 149 Series (8V149, 12V149, 16V149)

1957: Detroit Diesel Introduces the 149 Series

1960s: Expansion into the Marine and Industrial Sectors

1970s: Advancements in Power and Durability

1980s: Expansion into Power Generation and Military Applications

1990s: Focus on Fuel Efficiency and Emissions Control

Legacy and Continued Use in the 2000s and Beyond

Applications for Detroit Diesel 149 Series Engines (8V149, 12V149, 16V149)

Marine Applications

Industrial Applications

Off-Highway and Heavy-Duty Vehicle Applications

Specialized Applications

Key Features Of Detroit Diesel 149 Series Engines (8V149, 12V149, 16V149)

Two-Cycle Operation

Scavenging Air System

Durable Construction

High Power Density

Summary of Key Features

Read More

November 4, 2024

Importance of Regular Maintenance For Detroit Diesel 149 Series Engines (8V149, 12V149, 16V149)

Reinforcing the Value of Preventive Care and Regular Servicing to Maximize Engine Life

Key Preventive Maintenance Tasks for Maximizing Engine Life

The Long-Term Impact of Regular Maintenance

Parts For Detroit Diesel 149 Series Engines:

The Value of Professional Expertise with Diesel Pro Aftermarket Parts

Scenarios Where Professional Support and Diesel Pro Parts Are Essential

Parts and Resource Availability For Detroit Diesel 149 Series Engines (8V149, 12V149, 16V149)

Diesel Pro Power Parts for 149 Series Engines

Why Diesel Pro Power is the Go-To Source for Detroit Diesel 149 Series Parts

Read More

November 4, 2024

Oil and Coolant Levels: Verifying Levels Before Operation and Topping Off as Necessary

Visual Inspection: Checking for Leaks, Visible Wear, and Unusual Sounds

Benefits of Daily Checks

Filter Replacements: Changing Fuel and Oil Filters to Maintain Cleanliness

Component Inspections: Checking Air Filters, Fuel Lines, and Coolant Hoses for Wear

Additional Weekly and Monthly Checks

Benefits of Regular Weekly and Monthly Maintenance

Comprehensive Overhaul: Full Inspection and, if Necessary, Overhaul of Major Components Like the Cylinder Head and Valve Springs

Record Keeping: Maintaining a Detailed Log of Maintenance to Track Component Wear and Identify Recurring Issues

Read More

November 4, 2024

Causes: Clogged Coolant Passages, Malfunctioning Water Pump, or Inadequate Coolant Levels

Solutions: Flushing the Cooling System, Replacing the Water Pump, and Adding Coolant as Needed

Preventive Measures to Avoid Overheating

Symptoms: Engine Power Loss, Fuel Inefficiency, and Signs of Exhaust Gases Escaping

Repairs: Checking Head Gaskets, Replacing Damaged Gaskets, and Resealing Cylinder Heads

Preventive Measures to Avoid Compression Leaks

Injector Problems: Recognizing Clogged Injectors or Poor Fuel Delivery

Repair Tips: Cleaning Injectors, Replacing Damaged Fuel Lines, and Ensuring Proper Fuel Pressure

Symptoms: Poor Exhaust Flow, Engine Knocking, or Visible Damage on Valves

Solutions: Replacing Worn Valves and Adjusting Valve Clearances to Improve Engine Performance

Read More

November 4, 2024

Regular Tune-Ups For Detroit Diesel 149 Series Engines (8V149, 12V149, 16V149)

Safe Cleaning Methods: Steam, Solvent Tanks, and Compressed Air

Cleaning Critical Components: Careful Handling of Injector Tubes, Valves, and Head Gaskets

Replacing Worn Parts For Detroit Diesel 149 Series Engines (8V149, 12V149, 16V149)

Signs of Wear: Recognizing Fatigue in Parts Like Springs, Gaskets, and Liners

Procedure for Part Replacement: Step-by-Step Guidance on Replacing Valve Springs, Cylinder Head Gaskets, and Other Commonly Worn Parts

Read More

Page 7 of 8« First«...45678»

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588