November 4, 2024

Regular Tune-Ups For Detroit Diesel 149 Series Engines (8V149, 12V149, 16V149)

Safe Cleaning Methods: Steam, Solvent Tanks, and Compressed Air

Cleaning Critical Components: Careful Handling of Injector Tubes, Valves, and Head Gaskets

Replacing Worn Parts For Detroit Diesel 149 Series Engines (8V149, 12V149, 16V149)

Signs of Wear: Recognizing Fatigue in Parts Like Springs, Gaskets, and Liners

Procedure for Part Replacement: Step-by-Step Guidance on Replacing Valve Springs, Cylinder Head Gaskets, and Other Commonly Worn Parts

Read More

November 2, 2024

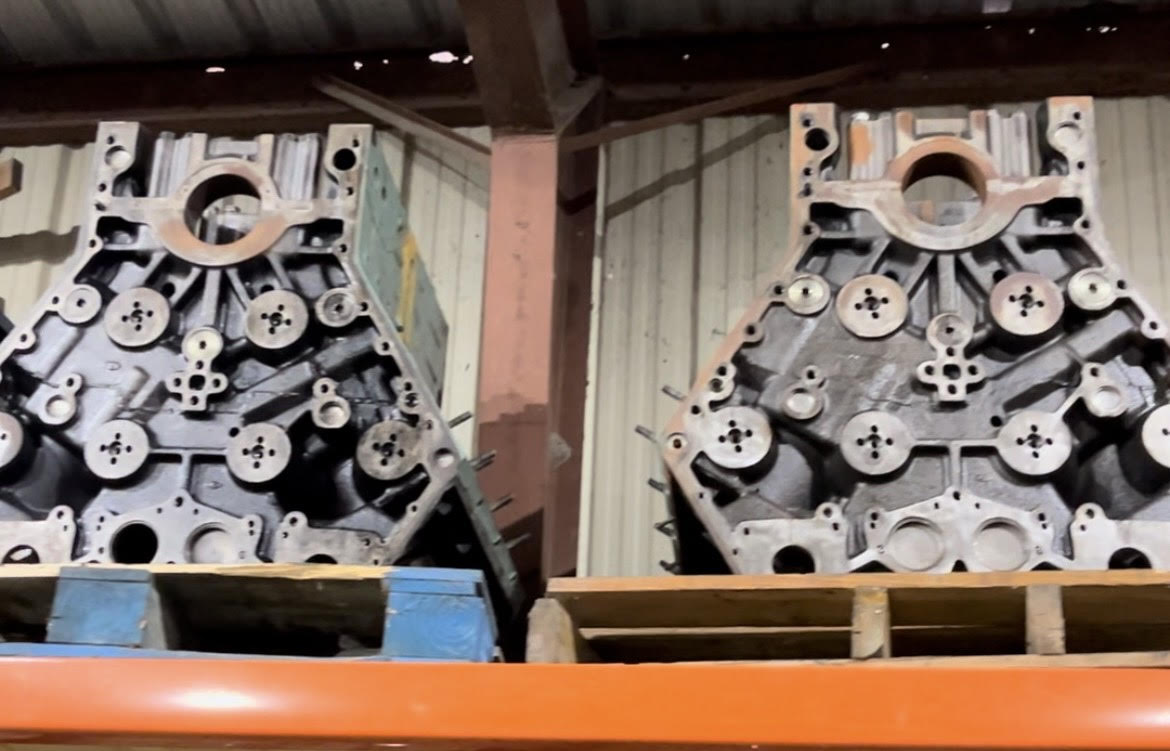

Structure and Role: The Engine’s Main Frame

Maintenance Tips: Ensuring Structural Integrity and Performance

Cleaning and Testing: Maintaining Optimal Condition

Key Functions: Housing Exhaust Valves, Fuel Injectors, and Cooling Systems

Common Issues: Addressing Wear, Valve Clearance, and Cylinder Head Replacement

Components and Operation: Fuel Pump, Filter, Injectors, and Manifold

Fuel Quality: Importance of Clean, High-Quality Fuel

Fuel Line Inspections: Checking for Leaks and Wear

Purpose and Components: Engine Water Jacket, Centrifugal Pump, and Consistent Water Flow

Scale and Corrosion: Preventing Buildup and Addressing Blocked Passages for Efficient Cooling

Exhaust System For Detroit Diesel 149 Series (8V149, 12V149, 16V149)

Components and Maintenance: Role of Exhaust Valves and Manifolds, Cleaning Buildup, and Ensuring Free Airflow

Inspection Tips: Detecting Exhaust Leaks or Valve Wear that Can Impact Engine Performance

Read More

November 2, 2024

Protective Gear Gear For Detroit Diesel 149 Series Engines (8V149, 12V149, 16V149)

Cautions with Moving Parts

Chemical Handling

Battery Disconnect: Precautions to Avoid Accidental Starting

Proper Lifting Techniques: Securing Heavy Components Correctly

Clean Workspace: Importance of a Clean, Organized Area

Tool Preparation: Recommendations for Quick, Organized Access

Read More

November 2, 2024

Two -Stroke Cycle Overview For Detroit Diesel 149 Series Engines (8V149, 12V149, 16V149)

Blower: Role in Air Intake and Maintaining Cylinder Pressure For The Detroit Diesel 149 Series (8V149, 12V149, 16V149)

1. Higher Power Density and Efficiency For The Detroit Diesel 149 Series (8V149, 12V149, 16V149)

2. Simplified Mechanical Design with Fewer Moving Parts For The Detroit Diesel 149 Series (8V149, 12V149, 16V149)

3. Enhanced Durability in High-Load Applications For The Detroit Diesel 149 Series (8V149, 12V149, 16V149)

4. Improved Scavenging and Cooling Efficiency For The Detroit Diesel 149 Series (8V149, 12V149, 16V149)

5. Adaptability to Demanding Environments For The Detroit Diesel 149 Series (8V149, 12V149, 16V149)

6. Fuel Flexibility and Efficiency For The Detroit Diesel 149 Series (8V149, 12V149, 16V149)

Read More

November 2, 2024

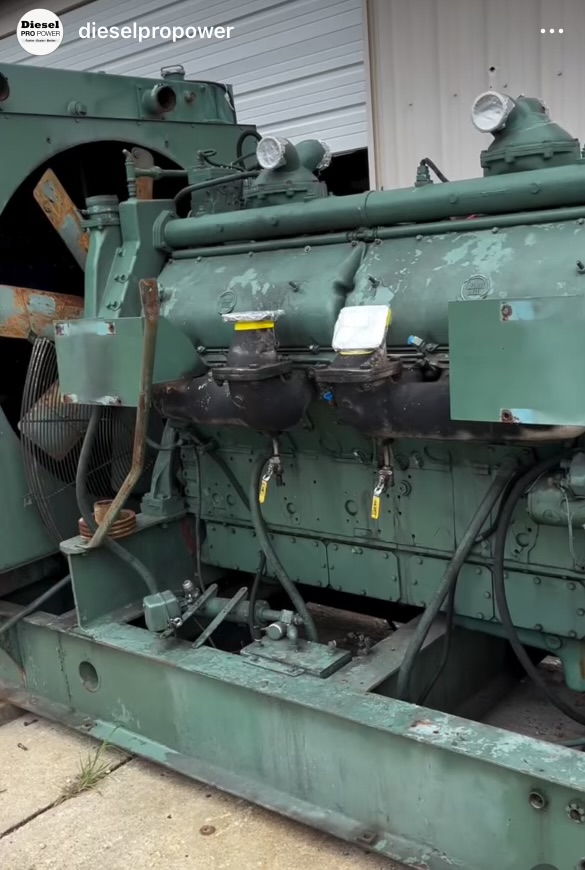

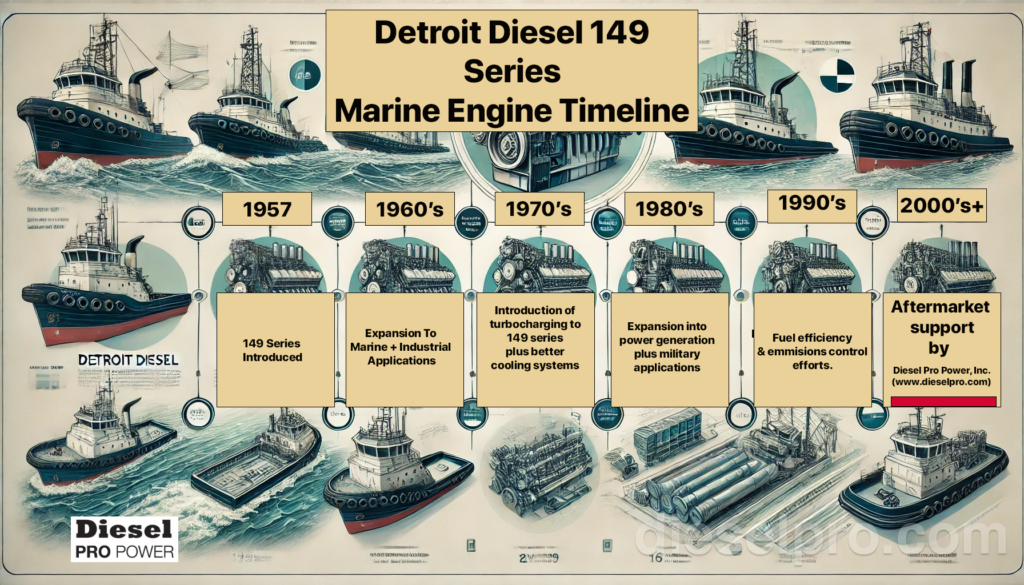

History and Development

Applications

Key Features

How Maintenance Supports Longevity

Reliability through Preventive Maintenance

Maintenance Intervals and Best Practices

Focus on Practical Use For The Detroit Diesel 149 Series Engines (8V149, 12V149, 16V149):

How This Guide Supports Practical Maintenance

Encouraging Professional Expertise for Complex Repairs

Read More

November 2, 2024

Focus on Practical Use:

Regular Tune-Ups:

Read More

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588