July 16, 2025

Cummins Parts Near Me: Get Quality Parts Shipped Fast From Diesel Pro Power

1. Why “Cummins Parts Near Me” Often Means Fast Nationwide Shipping

2. Specialized In Getting Cummins Marine Parts Near You Fast

3. Cylinder Heads For Cummins Engines: Precision Where It Matters Most

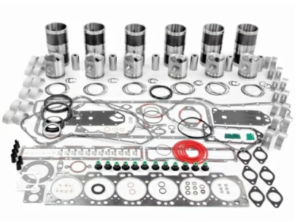

4. Overhaul Kits For Cummins Engines: Complete Solutions In One Shipment

5. Injectors For Cummins Engines: The Heartbeat Of Diesel Efficiency

6. Turbos For Cummins Engines: Reliable Boost For Marine & Industrial Power

7. Oil Pumps For Cummins Engines: Protecting The Lifeblood Of Your Diesel

8. Freshwater Pumps For Cummins Engines: Keeping Cool In Harsh Environments

9. Gaskets For Cummins Engines: The Unsung Heroes Of Longevity

10. Fuel Pumps For Cummins Engines: Precision In Every Gallon Delivered

11. Oil Filters & Fuel Filters For Cummins Engines: Protection Starts Here

12. Why Diesel Pro Power Is Your Best Answer To “Cummins Parts Near Me”

13. How To Get Your Cummins Parts Delivered Quickly

14. Ready To Get Started?

Final Word

Read More

March 26, 2025

Cummins 4B Engine Parts – Fresh Water Pump and Cooling System Components

Direct-Fit Fresh Water Pump Replacement

Thermostats for Cummins 4B Cooling Systems

Thermostat Gaskets and Seals

Belt Tensioners and Fan Drive Components

Belt Tensioners

Belts for Water Pump, Alternator, and Fan Drive

Available Inner Diameters:

Effective Diameter Ranges:

Supporting Cooling System Parts

Temperature Switch

Radiator Cleaner

Why Choose Diesel Pro Power for Cummins 4B Cooling System Parts?

Cummins 6B Engine Parts - Engine Water Pump & Cooling System Catalog

Freshwater Pump Options:

Water Pump Sealing Components

Thermostats & Temperature Regulation Components

Available Thermostats:

Thermostat Components:

Coolant Filtration

Belt Tensioners for Pump & Accessory Drive

Tensioner Options:

Available Belt Lengths:

Radiator & Cooling System Maintenance

Available Inside Diameters:

Clamp Features:

Why Choose Diesel Pro Power for Cummins 6B Cooling Parts?

Read More

January 31, 2025

Long-Term Care Strategies for Getting the Most Out of Your Engine

1. Prioritize Cooling System Maintenance

Signs of a Failing Raw Water Pump

Raw Water Pump Maintenance Tips

2. Perform Regular Oil & Filter Changes

Best Practices for Oil & Filter Changes

3. Keep the Fuel System Clean for Maximum Efficiency

4. Inspect & Maintain the Turbocharger

Turbocharger Maintenance Tips

5. Monitor Cylinder Heads & Perform Routine Overhauls

Signs That a Rebuild is Necessary

Benefits of Using a Caterpillar 3512 Rebuild Kit

6. Follow a Strict Preventive Maintenance Schedule

Essential Maintenance Schedule for the Caterpillar 3512

Final Thoughts: Maximize Engine Life with Proper Cooling & Maintenance

Key Takeaways

Looking for a Raw Water Pump or Rebuild Kit for Your Caterpillar 3512?

Read More

January 31, 2025

Practical steps to optimize fuel usage without sacrificing performance

1. Optimize the Fuel System for Maximum Efficiency

Key Fuel System Maintenance Steps:

2. Maintain the Turbocharger for Better Airflow & Combustion

Turbocharger Maintenance Tips

3. Keep the Aftercooler Clean to Prevent Overheating

Aftercooler Maintenance Tips:

4. Reduce Engine Idling & Optimize Load Management

How to Reduce Fuel Waste from Idling:

5. Maintain the Cooling System to Avoid Overheating & Inefficiency

Cooling System Maintenance Tips:

6. Use High-Quality Aftermarket Parts for Cost-Effective Maintenance

Essential Aftermarket Parts for Fuel Efficiency:

Final Thoughts: Maximizing Fuel Efficiency in the Caterpillar 3512

Key Takeaways:

Looking for Fuel System & Performance Parts for Your 3512?

Read More

January 31, 2025

What is an Aftercooler?

How the Aftercooler Works in Caterpillar 3512 and 3516 Engines

Step 1: Air Compression by the Turbocharger

Step 2: Heat Reduction in the Aftercooler

Step 3: Improved Combustion & Performance

Why Aftercoolers are Essential for Engine Health

1. Preventing Overheating

2. Improving Fuel Efficiency

3. Reducing Exhaust Emissions

4. Extending Engine Life

Signs That Your Aftercooler Needs Maintenance or Replacement

Maintaining Your Aftercooler: Best Practices

Aftercooler Replacement: When to Upgrade?

Reasons to Replace an Aftercooler:

Final Thoughts: Keeping Your Caterpillar 3512 & 3516 Running Cool

Need an Aftercooler Replacement? Diesel Pro Power Has You Covered!

Read More

January 14, 2025

The Difference Between the 6C, 6CT, 6CTA, ISC, and QSC Engines

Key Differences at a Glance

1. Cummins 6C Engine

Key Points:

Details:

Cummins 6C Parts Catalog

2. Cummins 6CT Engine

Key Points:

Details:

Cummins 6CT Parts Catalog

3. Cummins 6CTA Engine

Key Points:

Details:

Cummins 6CTA Parts Catalog

4. Cummins ISC Engine

Key Points:

Details:

Cummins ISC Parts Catalog

5. Cummins QSC Engine

Key Points:

Details:

Cummins QSC Parts Catalog

Choosing the Right Engine for Your Needs

Read More

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588