July 16, 2025

Cummins Parts Near Me: Get Quality Parts Shipped Fast From Diesel Pro Power

1. Why “Cummins Parts Near Me” Often Means Fast Nationwide Shipping

2. Specialized In Getting Cummins Marine Parts Near You Fast

3. Cylinder Heads For Cummins Engines: Precision Where It Matters Most

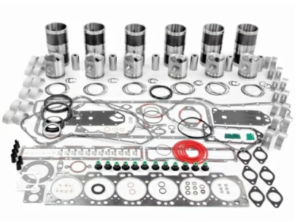

4. Overhaul Kits For Cummins Engines: Complete Solutions In One Shipment

5. Injectors For Cummins Engines: The Heartbeat Of Diesel Efficiency

6. Turbos For Cummins Engines: Reliable Boost For Marine & Industrial Power

7. Oil Pumps For Cummins Engines: Protecting The Lifeblood Of Your Diesel

8. Freshwater Pumps For Cummins Engines: Keeping Cool In Harsh Environments

9. Gaskets For Cummins Engines: The Unsung Heroes Of Longevity

10. Fuel Pumps For Cummins Engines: Precision In Every Gallon Delivered

11. Oil Filters & Fuel Filters For Cummins Engines: Protection Starts Here

12. Why Diesel Pro Power Is Your Best Answer To “Cummins Parts Near Me”

13. How To Get Your Cummins Parts Delivered Quickly

14. Ready To Get Started?

Final Word

Read More

July 14, 2025

Introduction: The Heart of Marine Fuel Delivery

Why Fuel Pumps Matter in Marine Diesel Engines

The Critical Role in Combustion

The Demands of the Marine Environment

The Two Major Types of Marine Diesel Fuel Pumps

1. Mechanical Injection Pumps

2. Electronic Unit Injectors (EUI) & High-Pressure Common Rail (HPCR)

A Deep Dive Into Fuel Pumps by Manufacturer

Cummins Marine Diesel Fuel Pumps

Detroit Diesel Marine Diesel Fuel Pumps

Caterpillar Marine Diesel Fuel Pumps

Fuel Pump Problems Specific to Marine Diesel Engines

Salt Contamination

Fuel Dilution and Bacterial Growth

Aeration and Cavitation

Comparing Fuel Pumps Across Cummins, Detroit Diesel, and Caterpillar

Selecting or Replacing a Marine Diesel Fuel Pump

Key Considerations

Don’t Overlook Compatibility

Maintenance Best Practices for Long Fuel Pump Life

For Mechanical Systems

For Electronic & Common Rail

Universal Marine Tips

Frequently Asked Questions

Can I retrofit an old Detroit Diesel with an electronic fuel pump?

Is marine fuel different? Why do pumps fail faster?

What’s the lifespan of a marine diesel fuel pump?

Conclusion: Respect the Fuel Pump, Extend Your Marine Engine’s Life

Read More

January 31, 2025

1. Perform Regular Oil Changes

Why It’s Important:

Oil Change Best Practices:

2. Inspect and Maintain the Cooling System

Why It’s Important:

Cooling System Maintenance Checklist:

3. Keep the Fuel System Clean

Why It’s Important:

Fuel System Maintenance Steps:

4. Inspect & Maintain the Turbocharger

Why It’s Important:

Turbocharger Maintenance Tips:

5. Monitor the Cylinder Head & Valve System

Why It’s Important:

Cylinder Head & Valve Maintenance Steps:

6. Maintain the Aftercooler System

Why It’s Important:

Aftercooler Maintenance Tips:

7. Check and Replace Worn Belts & Hoses

Why It’s Important:

Preventive Maintenance for Belts & Hoses:

8. Keep Exhaust & Emissions System Clean

Why It’s Important:

Exhaust System Maintenance Checklist:

Final Thoughts: Keep Your Caterpillar 3512 Running Strong

Key Takeaways:

Need Aftermarket Parts for Your 3512?

Read More

January 14, 2025

The Difference Between the 6C, 6CT, 6CTA, ISC, and QSC Engines

Key Differences at a Glance

1. Cummins 6C Engine

Key Points:

Details:

Cummins 6C Parts Catalog

2. Cummins 6CT Engine

Key Points:

Details:

Cummins 6CT Parts Catalog

3. Cummins 6CTA Engine

Key Points:

Details:

Cummins 6CTA Parts Catalog

4. Cummins ISC Engine

Key Points:

Details:

Cummins ISC Parts Catalog

5. Cummins QSC Engine

Key Points:

Details:

Cummins QSC Parts Catalog

Choosing the Right Engine for Your Needs

Read More

December 31, 2024

Why Injector and Valve Adjustments Are Critical For Detroit Diesel 53 Series Engines (3-53, 4-53, 6V53, 8V53)

Required Tools and Equipment

Preparatory Steps

Injector Timing Adjustment Procedure For Detroit Diesel 53 Series Engines (3-53, 4-53, 6V53, 8V53)

Valve Adjustment Procedure For Detroit Diesel 53 Series Engines (3-53, 4-53, 6V53 & 8V53)

Step 1: Inspect Valve Components

Step 2: Measure Valve Clearance

Step 3: Adjust Valve Clearance

Step 4: Verify the Adjustment

Follow the Firing Order

Post-Adjustment Verification For Detroit Diesel 53 Series Engines (3-53, 4-53, 6V53, 8V53)

Additional Considerations

Common Issues and Troubleshooting

Best Practices and Maintenance Tips

Troubleshooting Common Problems

Symptom: Loss of Power

Symptom: Excessive Noise

Symptom: Poor Fuel Efficiency

Conclusion

Read More

December 10, 2024

Advanced Injector Timing Techniques

Key Steps for Injector Timing

Governor Linkage Adjustments

Fuel Line Inspection and Replacement Guide

Inspection Procedures

Replacement Guide

Best Practices for Fuel Systems

Conclusion

Read More

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588