July 16, 2025

Cummins Parts Near Me: Get Quality Parts Shipped Fast From Diesel Pro Power

1. Why “Cummins Parts Near Me” Often Means Fast Nationwide Shipping

2. Specialized In Getting Cummins Marine Parts Near You Fast

3. Cylinder Heads For Cummins Engines: Precision Where It Matters Most

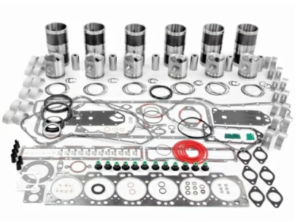

4. Overhaul Kits For Cummins Engines: Complete Solutions In One Shipment

5. Injectors For Cummins Engines: The Heartbeat Of Diesel Efficiency

6. Turbos For Cummins Engines: Reliable Boost For Marine & Industrial Power

7. Oil Pumps For Cummins Engines: Protecting The Lifeblood Of Your Diesel

8. Freshwater Pumps For Cummins Engines: Keeping Cool In Harsh Environments

9. Gaskets For Cummins Engines: The Unsung Heroes Of Longevity

10. Fuel Pumps For Cummins Engines: Precision In Every Gallon Delivered

11. Oil Filters & Fuel Filters For Cummins Engines: Protection Starts Here

12. Why Diesel Pro Power Is Your Best Answer To “Cummins Parts Near Me”

13. How To Get Your Cummins Parts Delivered Quickly

14. Ready To Get Started?

Final Word

Read More

January 31, 2025

1. Perform Regular Oil Changes

Why It’s Important:

Oil Change Best Practices:

2. Inspect and Maintain the Cooling System

Why It’s Important:

Cooling System Maintenance Checklist:

3. Keep the Fuel System Clean

Why It’s Important:

Fuel System Maintenance Steps:

4. Inspect & Maintain the Turbocharger

Why It’s Important:

Turbocharger Maintenance Tips:

5. Monitor the Cylinder Head & Valve System

Why It’s Important:

Cylinder Head & Valve Maintenance Steps:

6. Maintain the Aftercooler System

Why It’s Important:

Aftercooler Maintenance Tips:

7. Check and Replace Worn Belts & Hoses

Why It’s Important:

Preventive Maintenance for Belts & Hoses:

8. Keep Exhaust & Emissions System Clean

Why It’s Important:

Exhaust System Maintenance Checklist:

Final Thoughts: Keep Your Caterpillar 3512 Running Strong

Key Takeaways:

Need Aftermarket Parts for Your 3512?

Read More

January 31, 2025

Why Oil Changes Matter for the Caterpillar 3512 & 3516

1. Lubrication: Reducing Friction & Wear

2. Cooling: Preventing Overheating & Thermal Damage

3. Contaminant Removal: Keeping Your Engine Clean

4. Extending Engine Life & Reducing Downtime

How Often Should You Change the Oil?

Best Practice:

Choosing the Right Oil for Your Caterpillar 3512 & 3516 Engine

Key Features to Look for in Marine Engine Oil:

Signs That Your Engine Needs an Oil Change Sooner

The Role of Aftermarket Parts in Oil System Maintenance

Essential Aftermarket Parts for Oil System Maintenance:

Conclusion: Routine Oil Changes Protect Your Investment

Need Aftermarket Parts for Your Caterpillar 3512 or 3516?

Read More

January 14, 2025

The Difference Between the 6C, 6CT, 6CTA, ISC, and QSC Engines

Key Differences at a Glance

1. Cummins 6C Engine

Key Points:

Details:

Cummins 6C Parts Catalog

2. Cummins 6CT Engine

Key Points:

Details:

Cummins 6CT Parts Catalog

3. Cummins 6CTA Engine

Key Points:

Details:

Cummins 6CTA Parts Catalog

4. Cummins ISC Engine

Key Points:

Details:

Cummins ISC Parts Catalog

5. Cummins QSC Engine

Key Points:

Details:

Cummins QSC Parts Catalog

Choosing the Right Engine for Your Needs

Read More

December 18, 2024

Introduction

Types of Oil Pumps for Detroit Diesel V71 Engines

Gear-Driven Oil Pumps

Scavenging Oil Pumps

Oil Pump Operation: Working Principles for Detroit Diesel V71 Engines

Maintenance Insights and Recommendations

Role in Engine Longevity

Maintenance Procedures for Oil Pumps

Removal

Inspection

Reassembly

Installation

Advanced Maintenance and Troubleshooting

Common Issues and Solutions

Conclusion

Read More

December 18, 2024

Overview: Components and Their Functions

Key Components of the Lubrication System

Oil Pump for Detroit Diesel V71 Enginesfor Detroit Diesel V71 Engines

Oil Pump Operation

Maintenance Procedures for Oil Pumps

Common Oil Pressure Issues and Troubleshooting

Maintenance and Adjustment of Pressure Valves

Oil Filters for Detroit Diesel V71 Engines

Replacing the Oil Filter

Cleaning, Inspection, and Maintenance

Importance of Lubrication System Maintenance

Read More

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588