February 4, 2025

Key Takeaways

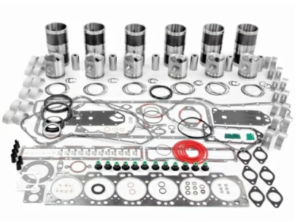

What’s Included in a Quality Overhaul Kit?

Overhaul Kits by Series

Detroit Diesel 53 Series Overhaul Kits

Detroit Diesel 71 Series Overhaul Kits

Detroit Diesel 92 Series Overhaul Kits

Detroit Diesel 149 Series Overhaul Kits

Benefits of Overhauling Your Detroit 2-Cycle Engine

Why Choose an Overhaul Instead of a Replacement?

1. Cost Savings

2. Extended Engine Life

3. Improved Fuel Efficiency

4. Minimized Downtime

5. Maintaining Engine Compatibility

Choosing the Right Overhaul Kit

Ensuring Compatibility for Maximum Performance

Aftermarket Vs. OEM & Why Aftermarket Is The Better Choice

Understanding the Difference

Why Aftermarket Is the Better Choice

Final Thoughts

Maximizing Engine Life and Performance

Read More

January 31, 2025

Long-Term Care Strategies for Getting the Most Out of Your Engine

1. Prioritize Cooling System Maintenance

Signs of a Failing Raw Water Pump

Raw Water Pump Maintenance Tips

2. Perform Regular Oil & Filter Changes

Best Practices for Oil & Filter Changes

3. Keep the Fuel System Clean for Maximum Efficiency

4. Inspect & Maintain the Turbocharger

Turbocharger Maintenance Tips

5. Monitor Cylinder Heads & Perform Routine Overhauls

Signs That a Rebuild is Necessary

Benefits of Using a Caterpillar 3512 Rebuild Kit

6. Follow a Strict Preventive Maintenance Schedule

Essential Maintenance Schedule for the Caterpillar 3512

Final Thoughts: Maximize Engine Life with Proper Cooling & Maintenance

Key Takeaways

Looking for a Raw Water Pump or Rebuild Kit for Your Caterpillar 3512?

Read More

January 31, 2025

Signs That a Rebuild is Necessary and What to Expect From the Process

1. Signs That Your Caterpillar 3512 Needs a Rebuild

1.1. Loss of Power and Performance

1.2. Excessive Exhaust Smoke (Black, White, or Blue Smoke)

1.3. High Oil Consumption & Low Oil Pressure

1.4. Overheating Issues & Coolant Loss

1.5. Knocking Sounds or Abnormal Engine Noise

2. What to Expect From the Rebuild Process

Step 1: Engine Disassembly & Inspection

Step 2: Replacement of Worn Parts

Step 3: Machining & Resurfacing

3. Benefits of Rebuilding vs. Replacing the Engine

4. How to Extend Engine Life After a Rebuild

Final Thoughts: When to Rebuild Your Caterpillar 3512

Key Takeaways

Looking for Rebuild Kits & Parts for Your 3512?

Read More

January 14, 2025

The Difference Between the 6C, 6CT, 6CTA, ISC, and QSC Engines

Key Differences at a Glance

1. Cummins 6C Engine

Key Points:

Details:

Cummins 6C Parts Catalog

2. Cummins 6CT Engine

Key Points:

Details:

Cummins 6CT Parts Catalog

3. Cummins 6CTA Engine

Key Points:

Details:

Cummins 6CTA Parts Catalog

4. Cummins ISC Engine

Key Points:

Details:

Cummins ISC Parts Catalog

5. Cummins QSC Engine

Key Points:

Details:

Cummins QSC Parts Catalog

Choosing the Right Engine for Your Needs

Read More

December 9, 2024

Guidelines for Disassembly, Cleaning, and Inspection For 92 Series Engines (6V92 , 8V92, 12V92, 16V92)

1. Preparation for Disassembly

Clean the Exterior

Gather Necessary Tools and Documentation

1. Use Detroit Diesel-Approved Tools

2. Substitute the Manual with Verified Specifications

3. Supplementary Resources

4. Final Tips for Preparation

Drain Fluids

3. Disassembly Process

3. Cleaning and Inspection

Replacement of Key Components: Pistons, Liners, Bearings

1. Pistons

2. Cylinder Liners

3. Bearings

Overhaul Kits For Detroit Diesel 92 Series

Reassembly Tips

Follow Manufacturer Specifications

Cylinder Head Bolts

Main Bearing Cap Bolts

Connecting Rod Bolts

Injector Hold-Down Bolts

Exhaust Manifold Bolts

Flywheel Bolts

Thermostat Housing Bolts

Valve Clearance (Cold)

Injector Timing Plunger Travel

Piston-to-Cylinder Wall Clearance

Main Bearing Clearance

Connecting Rod Bearing Clearance

Step-by-Step Assembly Sequence

Lubricate Moving Parts

Test Fit Components

Conclusion

Read More

December 2, 2024

Comprehensive Inspection

Inspection of Major Components

Compression Test

Gasket and Seal Replacement

Replacement Guidelines

Electrical System Load Testing

Testing and Replacement

Preventive Replacement of Components

Key Components

Full List of Cooling System Links for Detroit Diesel 92 Series Engines (6V92, 8V92, 12V92, 16V92)

Read More

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588