General Information

Q: What does this manual cover?

This manual provides instructions for operating, maintaining, and overhauling Detroit Diesel V-71 engines, including 6V71, 8V71, 12V71, and 16V71 models. It also includes specifications, safety guidelines, and troubleshooting procedures. Since this manual is now out of print, much of the information is available on Diesel Pro Power’s blog for easy access and reference.

Q: What is the V-71 engine series?

The V-71 series consists of two-stroke diesel engines available in 6, 8, 12, and 16-cylinder configurations. These engines are commonly used in industrial, marine, and power generation applications.

Q: Where can I find parts and technical assistance for V-71 engines?

Instead of OEM parts, Diesel Pro Power offers premium aftermarket parts designed to meet or exceed original specifications. Diesel Pro Power also provides technical resources and troubleshooting guides on their website.

Engine Specifications

Q: What are the key dimensions of the V-71 engines?

- Bore: 4.25 inches

- Stroke: 5 inches

- Compression Ratio:

- 17:1 for turbocharged engines

- 18.7:1 for naturally aspirated models

- Displacement:

- 426 cubic inches (6V71)

- 568 cubic inches (8V71)

- 852 cubic inches (12V71)

- 1136 cubic inches (16V71)

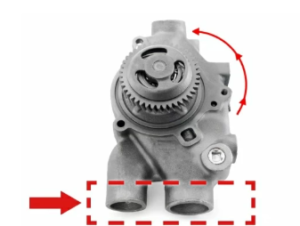

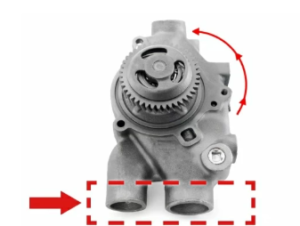

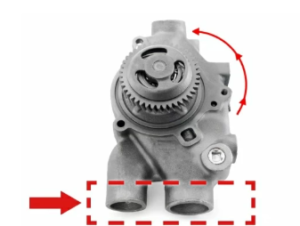

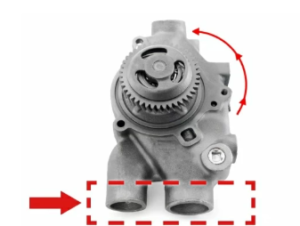

Q: What type of lubrication system is used?

The V-71 engines utilize a full-pressure lubrication system with a gear-driven oil pump, oil filter, and oil cooler. This system ensures even distribution of oil to all critical components for optimal performance and reduced wear.

Q: What type of fuel system does the engine use?

Each cylinder is equipped with a unit injector that sprays fuel directly into the combustion chamber. This system provides precise fuel delivery for efficient combustion, reducing emissions and maximizing power output.

Q: What materials are used in the engine construction?

The V-71 series engines use cast iron for the cylinder block and heads, ensuring durability. The pistons are typically made of aluminum alloy for lightweight and efficient heat dissipation.

Q: What are the firing orders for these engines?

- 6V71: 1R-4L-2R-3L-3R-2L-4R-1L

- 8V71: 1R-5L-2R-3L-3R-2L-4R-1L

- 12V71: 1R-5L-3R-7L-2R-6L-4R-8L

- 16V71: 1R-8L-3R-6L-5R-2L-7R-4L

Q: How are the engines cooled?

The V-71 engines utilize a closed-loop cooling system with a centrifugal water pump and heat exchanger or radiator. Coolant is circulated through the engine block and cylinder heads to maintain optimal operating temperatures.

Q: What is the purpose of the blower in the V-71 engines?

The blower ensures a continuous supply of fresh air into the cylinders for combustion and scavenging of exhaust gases. This is essential for the two-stroke cycle operation of the engine.

Q: What types of turbocharging options are available?

The V-71 engines offer turbocharged and turbo-aftercooled configurations for enhanced power output and efficiency. Turbocharging increases air intake, while aftercooling reduces air temperature for better combustion.

Q: What are the main applications of V-71 engines?

The V-71 series engines are commonly used in:

- Marine: Powering fishing boats, tugboats, and yachts.

- Industrial: Generators, compressors, and pumps.

- Trucking: Heavy-duty transport vehicles.

- Military: Ground vehicles and stationary power units.

Q: How is engine timing achieved in the V-71 series?

Engine timing is controlled by a precisely aligned gear train that drives the camshafts and injectors. The timing ensures synchronization between fuel injection, valve operation, and crankshaft rotation.

Q: What are the standard operating pressures for the lubrication system?

- Normal operating oil pressure is maintained at 50 psi.

- A relief valve prevents oil pressure from exceeding 100 psi (6V71/8V71) or 120 psi (12V71/16V71).

Q: What safety features are integrated into the V-71 engines?

- Fuse Plugs: Melt at critical temperatures to indicate overheating.

- Pressure Regulators: Maintain steady oil and fuel pressures.

- Blower Bypass Valves: Prevent overpressure in the air system.

Q: What kind of starting system is used?

The engines are equipped with electric or hydraulic starting systems, depending on the application. Electric starters draw power from a battery, while hydraulic starters use pressurized fluid.

Q: How does the compression ratio affect engine performance?

- Higher compression ratios in naturally aspirated models (18.7:1) improve thermal efficiency and torque.

- Turbocharged engines (17:1) benefit from forced air intake, balancing the slightly lower compression with increased power output.

Q: Are the components interchangeable between different models?

Yes, many major components such as pistons, connecting rods, cylinder liners, and injectors are interchangeable across the V-71 series, simplifying maintenance and part replacement.

Q: What aftermarket parts are recommended for replacement?

Diesel Pro Power offers high-quality aftermarket parts, including pistons, injectors, turbochargers, and gaskets, which are designed to meet or exceed the original specifications of the V-71 series engines.

Operation and Maintenance

Q: What is the recommended operating temperature?

The engine coolant temperature should be maintained between 160°F and 185°F for optimal performance. Operating outside this range can lead to inefficient combustion or potential engine damage.

Q: How often should the oil and filters be changed?

Oil and filters should be changed every 100 to 200 hours of operation, or as recommended based on the analysis of used oil and operating conditions. Heavy-duty service may require more frequent changes to ensure proper lubrication and reduce engine wear.

Q: What are the daily maintenance checks?

- Inspect oil and coolant levels and refill if necessary.

- Check for leaks in the fuel, oil, and coolant systems.

- Ensure the air cleaner is clean and the exhaust system is free of obstructions.

- Verify the integrity of hoses, clamps, and belts, replacing any worn or damaged components.

- Ensure the dipstick reading reflects the proper oil level after allowing the engine to sit for at least 20 minutes.

Q: What is the proper procedure for starting the engine?

- Verify all controls are set to their correct positions and the transmission is in neutral.

- Check oil and coolant levels.

- Engage the ignition switch or hydraulic starting system.

- Allow the engine to idle and warm up to the recommended operating temperature before applying any load.

Q: How often should coolant be replaced?

Coolant should be replaced every 1,000 hours of operation or annually, whichever comes first. This helps prevent corrosion, scaling, and overheating.

Q: How can I reduce exhaust smoke?

- Ensure injectors are functioning correctly and free of carbon deposits.

- Use clean diesel fuel and replace filters regularly.

- Maintain proper valve and injector timing.

- Keep the air cleaner and exhaust system unobstructed.

Q: How can I prevent fuel contamination?

- Drain water separators daily, especially in humid or cold environments.

- Use clean fuel containers and sources to avoid debris and water contamination.

- Replace fuel filters every 250 hours or sooner if blockages are suspected.

Q: What is the proper procedure for shutting down the engine?

Allow the engine to idle for 3 to 5 minutes before shutting it down. This reduces thermal stress on turbochargers and allows oil to circulate properly, cooling critical components.

Q: How do I prepare the engine for cold weather operation?

- Use winter-grade diesel fuel with anti-gel additives.

- Install an engine block heater to preheat the coolant and block.

- Switch to lower-viscosity oil suitable for cold temperatures.

- Check battery charge and ensure connections are clean and tight.

Q: What steps should be taken for hot weather operation?

- Ensure proper coolant levels and inspect the radiator for blockages.

- Use high-viscosity oil suited for high-temperature environments.

- Verify that the cooling system is functioning correctly, including the fan, belts, and water pump.

Q: How should I clean the air intake system?

- Remove and inspect the air filter element for dirt or debris.

- Clean reusable filters with compressed air or replace disposable filters.

- Inspect the intake ducts for blockages and clean thoroughly.

Q: What should I do if the engine overheats?

- Stop the engine immediately to prevent damage.

- Check the coolant level and refill if necessary.

- Inspect for blockages in the radiator or heat exchanger.

- Verify the thermostat and water pump functionality and repair if required.

Q: How do I ensure proper lubrication system performance?

- Use oil that meets the SAE and API standards specified in the manual.

- Inspect for leaks in the oil lines, oil cooler, and gaskets.

- Replace oil and filters according to the recommended schedule to maintain system cleanliness.

Q: What is the recommended idle speed?

Idle speed should be maintained at 550 to 600 RPM for smooth operation and to prevent excessive wear or poor lubrication.

Q: What are the signs of inadequate lubrication?

- Low oil pressure readings on the gauge.

- Unusual engine noise or knocking.

- Overheating due to friction between moving parts.

- Visible oil leaks or higher-than-normal oil consumption.

Q: How do I clean the exterior of the engine?

- Use a degreaser to remove oil and grime.

- Rinse with warm water while avoiding electrical components.

- Dry thoroughly with compressed air to prevent rust or corrosion.

Q: What is the recommended maintenance schedule for belts and hoses?

Inspect belts and hoses every 100 hours for signs of cracking, fraying, or wear. Replace as needed to prevent failures.

Q: How can I extend the life of my engine?

- Follow the maintenance schedules outlined in the manual.

- Use high-quality fuel, oil, and filters.

- Monitor and address early signs of wear or performance issues.

- Avoid excessive idling or operating under constant overload conditions.

By adhering to these recommendations, operators can ensure optimal performance, reduce downtime, and extend the life of Detroit Diesel V-71 engines.

Troubleshooting

Q: What should I do if oil pressure is low?

- Check the oil level and ensure it is between the minimum and maximum marks on the dipstick.

- Inspect the oil pump for wear or malfunction, and replace it if necessary.

- Examine the pressure relief and regulator valves for blockages or damage, and ensure they operate within the specified pressure range.

- Verify there are no leaks in the lubrication system, including oil lines and seals.

- Ensure the oil being used meets the specifications for viscosity and API standards recommended for the engine.

Q: How can I identify and resolve coolant leaks?

- Use a pressure tester to check for leaks in the cooling system.

- Inspect hoses, clamps, and the radiator or heat exchanger for visible cracks or damage.

- Replace gaskets and seals that show signs of wear or leakage.

- Check for proper installation of the thermostat and ensure the water pump is functioning correctly.

- Inspect the cylinder head for cracks, especially if overheating has occurred.

Q: What steps should I take for poor engine performance?

- Replace clogged or worn fuel injectors to ensure proper fuel delivery.

- Check the air cleaner and intake ducts for blockages or excessive dirt.

- Verify valve timing and injector synchronization using the specifications provided in the manual.

- Measure compression in all cylinders to detect issues such as worn piston rings or valves.

- Inspect the fuel supply system for air leaks, contamination, or inadequate pressure.

Q: What causes excessive exhaust smoke?

- Black Smoke: Indicates incomplete combustion caused by clogged air filters, over-fueling, or incorrect injector timing.

- Blue Smoke: Suggests burning oil due to worn piston rings, valve seals, or turbocharger issues.

- White Smoke: Indicates unburned fuel, commonly caused by cold starts, faulty injectors, or low compression.

Q: What should I do if the engine overheats?

- Stop the engine immediately and allow it to cool.

- Check coolant levels and refill as needed.

- Inspect the radiator or heat exchanger for blockages or debris.

- Verify the operation of the water pump and thermostat.

- Examine the fan belt for proper tension and ensure the fan is functioning correctly.

Q: How can I resolve starting difficulties?

- Check the battery for sufficient charge and clean terminal connections.

- Verify the operation of the starter motor and solenoid.

- Inspect fuel lines and filters for clogs or air leaks.

- Ensure the fuel tank contains clean, uncontaminated diesel fuel.

- Check the compression and injector timing to ensure proper combustion.

Q: Why is there excessive vibration or noise during operation?

- Inspect the engine mounts for wear or damage and replace them if necessary.

- Check for loose or damaged components, such as belts, pulleys, or accessory drives.

- Verify proper alignment of the crankshaft and other rotating parts.

- Inspect pistons, connecting rods, and bearings for excessive wear or damage.

Q: What should I do if fuel consumption is abnormally high?

- Ensure the fuel injectors are functioning properly and replace them if necessary.

- Inspect for fuel leaks in the lines, filters, or connections.

- Verify air intake and exhaust systems are free of blockages.

- Check turbocharger performance in turbocharged models.

- Confirm that the engine is not running under excessive loads.

Q: What should I check if the engine produces low power?

- Inspect the fuel system for blockages, leaks, or low pressure.

- Verify the air intake and exhaust systems are clear of obstructions.

- Ensure turbochargers (if equipped) are operating within specifications.

- Check valve and injector timing for proper synchronization.

- Measure cylinder compression to identify potential mechanical issues.

Q: How can I address oil leaks?

- Tighten loose fittings and connections in the lubrication system.

- Replace worn gaskets, seals, or O-rings.

- Inspect the oil pan and drain plug for damage.

- Ensure the crankcase ventilation system is functioning properly to prevent pressure buildup.

Q: What causes irregular idling or stalling?

- Check for air leaks in the fuel system, which can disrupt fuel delivery.

- Inspect injectors for clogs or wear.

- Verify the idle speed setting and adjust if necessary.

- Inspect the governor for proper operation and settings.

Q: How can I troubleshoot low compression?

- Inspect pistons, rings, and cylinder liners for wear or damage.

- Check the cylinder head gasket for leaks or damage.

- Verify proper valve seating and adjust clearances as needed.

- Inspect the cylinder head and block for cracks or warping.

Q: What should I do if the alternator is not charging?

- Check the alternator belt for proper tension and condition.

- Inspect electrical connections and cables for corrosion or loose fittings.

- Test the alternator output voltage and replace it if not meeting specifications.

- Verify that the voltage regulator is functioning correctly.

By addressing these common issues promptly and systematically, you can maintain the reliable operation of Detroit Diesel V-71 engines and minimize downtime.

Safety Precautions

Q: What safety measures should be followed during engine service?

- Disconnect the battery to avoid accidental electrical shocks or shorts.

- Use proper lifting equipment to handle heavy components, such as cylinder heads or turbochargers, to prevent injury.

- Wear personal protective equipment (PPE), including safety glasses, gloves, steel-toed boots, and hearing protection.

- Ensure the engine is cool before performing maintenance to avoid burns from hot surfaces or fluids.

- Work in a well-ventilated area to avoid exposure to harmful fumes, especially during fuel or solvent handling.

- Keep fire extinguishers readily available when working with flammable materials like fuel and oil.

Q: How should hazardous materials like asbestos be handled?

- Avoid disturbing asbestos-containing materials unnecessarily.

- Wet old asbestos gaskets to prevent dust formation during removal.

- Dispose of asbestos-containing materials in compliance with local hazardous waste regulations.

- Use modern, asbestos-free alternatives, such as those offered by Diesel Pro Power, for replacement gaskets and seals.

Q: What precautions should be taken when working with pressurized systems?

- Relieve pressure from the system before servicing components like fuel lines, oil coolers, or the cooling system.

- Use caution when removing pressurized fittings, as residual pressure can release fluids forcefully.

- Wear face and hand protection to prevent injury from escaping fluids.

Q: What steps should be taken when working with high-temperature components?

- Allow the engine to cool completely before performing maintenance.

- Use insulated tools and gloves when working near hot exhaust manifolds, turbochargers, or cooling system components.

- Avoid placing flammable materials near hot engine parts to reduce fire risk.

Q: What should be done to ensure electrical safety during repairs?

- Disconnect the negative battery terminal before working on electrical components.

- Use insulated tools to prevent accidental shorts.

- Test circuits with a multimeter to verify they are de-energized before proceeding with repairs.

Q: How should fuel and oil spills be managed?

- Clean spills immediately using absorbent materials.

- Dispose of contaminated rags or absorbents in accordance with local environmental regulations.

- Keep spill containment kits nearby in areas where fuel or oil is handled frequently.

Q: What precautions should be taken when using solvents or cleaning agents?

- Use solvents in a well-ventilated area to prevent inhalation of harmful fumes.

- Avoid skin contact by wearing chemical-resistant gloves.

- Store solvents away from open flames or high temperatures to minimize fire hazards.

Q: What safety measures are required when working with rotating engine parts?

- Ensure the engine is turned off and the key is removed before working near belts, pulleys, or gears.

- Use proper lockout/tagout procedures to prevent accidental engine starts.

- Keep hands, tools, and clothing away from moving components during operation.

Q: What precautions should be taken with coolant and oil disposal?

- Drain coolant and oil into designated containers to prevent environmental contamination.

- Dispose of used fluids through certified recycling facilities.

- Avoid mixing different types of fluids, as this can complicate recycling processes.

Q: How should compressed air be used safely?

- Use compressed air at a pressure below 40 psi when cleaning components.

- Always wear safety goggles to protect your eyes from flying debris.

- Direct air streams away from yourself and others to avoid injuries.

Q: How can workspaces be kept safe during engine service?

- Keep work areas clean and organized to reduce tripping hazards.

- Ensure adequate lighting for visibility.

- Use proper storage for tools, chemicals, and parts to prevent accidents.

Q: What precautions should be taken during fuel system maintenance?

- Relieve fuel system pressure before disconnecting lines.

- Keep ignition sources away from fuel systems to reduce fire risk.

- Use drip pans to catch fuel leaks and dispose of the collected fuel properly.

Q: What are the emergency response measures for accidents during service?

- In case of burns, cool the affected area with water and seek medical attention.

- For chemical exposure, rinse the area thoroughly with water and refer to the product’s safety data sheet (SDS).

- If a fire occurs, use a Class B or Class C fire extinguisher for fuel or electrical fires.

By following these safety precautions, you can minimize the risks associated with servicing Detroit Diesel V-71 engines and ensure a safer working environment.

Overhaul and Assembly

Q: When should the engine be overhauled?

Overhaul is recommended when significant wear or performance issues are detected, such as:

- Low compression in one or more cylinders.

- Excessive oil consumption or leaks.

- High levels of vibration or abnormal noises.

- Difficulty maintaining oil pressure or overheating under normal operating conditions.

- A dramatic reduction in power output or fuel efficiency.

Q: What tools are required for disassembly and assembly?

- Precision Measurement Tools: Micrometers, dial indicators, and bore gauges to measure tolerances and clearances.

- Torque Wrenches: For accurately tightening bolts to specified values.

- Specialized Pullers: To safely remove gears, pulleys, and other press-fit components.

- Cleaning Equipment: Non-corrosive solvents, wire brushes, and compressed air for cleaning parts.

- Lifting Equipment: Engine hoists or cranes to manage heavy components like cylinder heads or crankshafts.

- Assembly Tools: Piston ring compressors, valve spring compressors, and alignment tools.

Q: How should parts be cleaned during an overhaul?

- Disassemble all components and remove loose dirt and oil using degreasers.

- Clean parts with a non-corrosive solvent to remove carbon deposits, sludge, and contaminants.

- Rinse thoroughly with water and dry immediately with compressed air.

- Inspect parts for cracks, wear, and deformation before reassembly.

- Coat cleaned metal surfaces with light oil to prevent rust during reassembly.

Q: How are cylinder liners inspected and replaced?

- Remove liners and inspect for scoring, pitting, or wear.

- Measure the bore diameter with a bore gauge to ensure it is within specifications.

- If wear exceeds tolerances, replace the liner and piston with matched components.

- Use the correct tools to press new liners into the block and ensure proper seating.

Q: What steps are involved in inspecting the crankshaft?

- Measure the journals for wear and compare against factory tolerances.

- Check for cracks using magnetic particle inspection.

- Inspect thrust bearings for wear or damage.

- Regrind journals and replace bearings as necessary to restore proper clearances.

Q: What precautions should be taken when reassembling the engine?

- Ensure all parts are thoroughly cleaned and free of debris.

- Use only specified torque values for fasteners.

- Apply assembly lubricant to bearings, cams, and other moving parts to prevent dry starts.

- Replace all gaskets and seals with new ones to ensure proper sealing.

- Align timing marks on gears precisely during camshaft and injector timing.

Q: What is the process for reassembling the cylinder head?

- Clean the cylinder head and inspect for cracks or warping.

- Replace all valve guides and grind valve seats to proper angles.

- Install new valves, springs, and retainers, ensuring proper alignment and clearance.

- Check the rocker arms and adjust them to the specified valve lash.

- Install the cylinder head using a new gasket and tighten bolts in the correct sequence to the specified torque.

Q: How should pistons and connecting rods be handled during an overhaul?

- Inspect pistons for cracks, scoring, or excessive wear.

- Measure piston ring end gaps and replace rings if they exceed wear limits.

- Check connecting rods for straightness and inspect the big end bore for proper size.

- Assemble pistons and rods carefully, ensuring proper orientation and installation of wrist pins.

Q: How should the camshaft be inspected?

- Measure camshaft lobes for wear and verify that they meet tolerances.

- Inspect camshaft bearings for pitting or scoring and replace if necessary.

- Ensure cam timing is correct during reassembly to maintain proper valve and injector operation.

Q: What steps are involved in timing the engine?

- Align the crankshaft and camshaft timing marks according to the manual.

- Set injector and valve timing to specified values using precision gauges.

- Verify timing after assembly by rotating the engine manually to ensure proper synchronization.

Q: How should the lubrication system be inspected during an overhaul?

- Remove and inspect the oil pump for wear or damage.

- Check oil galleries for blockages and clean thoroughly.

- Replace all oil seals and gaskets.

- Install a new oil filter and refill with fresh oil that meets engine specifications.

Q: What are common mistakes to avoid during engine assembly?

- Using worn or damaged parts instead of replacing them.

- Overtightening bolts, which can damage threads or components.

- Failing to properly clean and inspect parts, leading to premature failure.

- Neglecting to use assembly lubricants, increasing the risk of dry starts.

Q: What should be done before starting the engine after an overhaul?

- Prime the lubrication system to ensure oil is circulated before startup.

- Rotate the engine manually to check for proper timing and interference.

- Inspect all connections, including fuel, oil, and coolant systems, for leaks or improper installation.

- Perform a break-in procedure, gradually increasing the load on the engine to seat components properly.

Q: How often should the engine be inspected after an overhaul?

- Perform a detailed inspection after the first 50 hours of operation to check for leaks or abnormal wear.

- Regular maintenance should resume according to the manual’s recommended intervals.

By following these guidelines and ensuring precision at every step, you can perform a successful overhaul and reassembly, restoring your Detroit Diesel V-71 engine to optimal performance.

Lubrication and Cooling Systems

Q: How is the lubrication system designed?

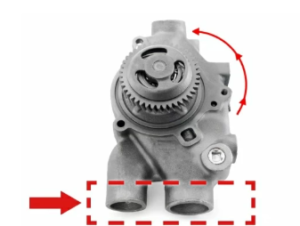

The lubrication system uses a gear-driven oil pump to draw oil from the sump, circulate it through an oil filter and cooler, and distribute it to all critical engine components. It operates under pressure to ensure efficient lubrication and cooling of moving parts, including bearings, pistons, and valve mechanisms.

Q: What are the key components of the lubrication system?

- Oil Pump: Gear-driven and located in the front cover or main bearing caps, depending on the model.

- Oil Cooler: Regulates oil temperature to maintain viscosity and prevent overheating.

- Oil Filter: Removes contaminants from the oil to protect engine components.

- Pressure Regulator Valve: Maintains stable oil pressure under varying conditions.

- Relief Valve: Protects the system by diverting excess pressure back to the sump.

Q: What should I do if the oil cooler becomes clogged?

- Remove the oil cooler core and inspect it for blockages or damage.

- Clean the core using non-corrosive solvents and flush thoroughly with water.

- Pressure test the core for leaks, replacing it if necessary.

- Reinstall using new gaskets and ensure all connections are secure.

Q: How often should the oil be replaced in the lubrication system?

The oil should be replaced every 100-200 hours of operation, depending on engine usage and conditions. Always use oil that meets the viscosity and API standards recommended in the manual.

Q: What should I check if oil pressure is too high or too low?

- Low Oil Pressure: Check oil levels, inspect the oil pump for wear, and verify the condition of the pressure relief valve.

- High Oil Pressure: Inspect the oil pressure regulator for blockages or malfunction and ensure the oil cooler bypass valve is functioning properly.

Q: How should the cooling system be maintained?

- Daily Checks: Verify coolant levels and inspect for leaks.

- Regular Inspections: Check hoses for cracks, bulges, or wear, and replace as necessary.

- Radiator Maintenance: Clean the radiator or heat exchanger to remove debris that could block airflow or water flow.

- Thermostat Function: Ensure the thermostat opens and closes properly to regulate coolant flow and maintain the engine’s operating temperature.

Q: What are the primary components of the cooling system?

- Water Pump: Circulates coolant through the engine and radiator or heat exchanger.

- Radiator/Heat Exchanger: Dissipates heat from the coolant.

- Thermostat: Regulates the flow of coolant based on engine temperature.

- Coolant Hoses and Connections: Transport coolant between the engine and the radiator or heat exchanger.

Q: What should I do if the engine overheats?

- Stop the engine immediately to prevent damage.

- Check coolant levels and refill if necessary.

- Inspect the radiator or heat exchanger for blockages and clean as needed.

- Verify the operation of the thermostat and water pump.

- Ensure the fan and belts are functioning properly and replace any damaged components.

Q: How do I prevent coolant leaks?

- Regularly inspect gaskets, seals, and hoses for signs of wear or damage.

- Use high-quality clamps to secure hose connections.

- Pressure test the system periodically to identify weak points or leaks.

Q: What type of coolant should be used?

Use a coolant that meets the specifications outlined in the manual, typically a mix of ethylene glycol and water in a 50:50 ratio. The coolant should include corrosion inhibitors to protect internal components.

Q: What causes low coolant flow, and how can it be addressed?

- Cause: Clogged radiator, damaged water pump, or blocked hoses.

- Solution: Clean or replace the radiator, inspect and repair the water pump, and clear blockages in the hoses.

Q: What is the role of the thermostat in the cooling system?

The thermostat regulates coolant flow based on engine temperature. It remains closed during cold starts to help the engine warm up quickly and opens as the engine reaches operating temperature to allow coolant to circulate through the radiator.

Q: How can the lubrication system be protected from contamination?

- Use high-quality oil and replace it regularly.

- Replace oil filters at each oil change.

- Inspect and clean the oil sump during overhauls.

- Ensure proper sealing of gaskets and connections to prevent contaminants from entering the system.

Q: What maintenance is required for the water pump?

- Inspect the pump for leaks and proper operation.

- Check the condition of the pump bearings and replace if noisy or worn.

- Ensure the pump impeller is free of debris and damage.

Q: How should the oil and coolant systems be cleaned during maintenance?

- Oil System: Use a flushing oil or solvent to clean internal components. Replace oil filters and refill with fresh oil.

- Cooling System: Drain the old coolant, flush the system with clean water, and refill with fresh coolant mixed to the proper ratio.

Q: How often should the coolant be replaced?

Replace coolant every 1,000 hours or annually, whichever comes first, to maintain optimal cooling system performance and prevent corrosion or scaling.

Q: What is the function of the oil cooler bypass valve?

The bypass valve ensures that oil continues to flow through the engine even if the oil cooler becomes clogged. This prevents a complete loss of lubrication under such circumstances.

By maintaining and regularly inspecting the lubrication and cooling systems, you can ensure reliable operation, extend the engine’s lifespan, and avoid costly breakdowns.

Cylinder Head and Valve Maintenance

Q: What are common signs of cylinder head issues?

- Coolant Leaks: Look for coolant seeping around the cylinder head gasket or into the combustion chamber.

- Poor Compression: Indicated by reduced engine power or difficulty starting.

- Cracks in the Head: These may be visible during inspection or detected through pressure testing.

- Excessive Smoke: Blue or white smoke from the exhaust may indicate cylinder head or valve issues.

- Overheating: Persistent overheating can be caused by a warped or cracked cylinder head.

Q: How are valve clearances adjusted?

- Rotate the engine manually to ensure the piston is at top dead center (TDC) on the compression stroke for the cylinder being adjusted.

- Use a feeler gauge to measure the gap between the rocker arm and the valve stem.

- Loosen the lock nut on the adjusting screw and turn the screw to achieve the specified clearance.

- Tighten the lock nut and recheck the clearance to confirm accuracy.

Q: What causes valve clearance to change over time?

- Wear: On valve seats, stems, or rocker arms.

- Thermal Expansion: Repeated heating and cooling cycles can alter clearances.

- Deposits: Carbon buildup on valves may affect seating and clearance.

Q: How often should valve adjustments be performed?

Valve clearances should be checked and adjusted every 500 to 1,000 hours of operation, or as recommended by the engine’s usage conditions.

Q: What steps should be taken when replacing the cylinder head gasket?

- Remove the cylinder head and thoroughly clean the mating surfaces on the head and block.

- Inspect the cylinder head for warping or cracks and repair or replace as necessary.

- Install a new gasket, ensuring it is positioned correctly.

- Tighten the cylinder head bolts in the specified sequence and torque them to the recommended values.

Q: How can I test for a cracked cylinder head?

- Use a pressure test: Seal the coolant passages and pressurize the system to detect leaks.

- Perform a dye penetrant test: Apply a dye to the head and inspect for cracks under UV light.

- Check for combustion gases in the coolant: This can indicate a head crack or gasket failure.

Q: What is the purpose of valve lash adjustment?

Valve lash ensures proper operation of the valve train by allowing for thermal expansion of the components. Incorrect lash can lead to reduced performance, increased wear, or valve damage.

Q: How are valve springs inspected?

- Measure free length and compare it to the specified limits.

- Check for visible signs of wear, cracks, or deformation.

- Replace springs that are weak, damaged, or out of specification.

Q: How should valve seats be maintained?

- Inspect for pitting, wear, or improper seating.

- Regrind the seats using the correct angle as specified in the manual.

- Ensure the valve seats evenly and seals properly with the valve face.

Q: What tools are required for cylinder head and valve maintenance?

- Valve spring compressor for removing and installing springs.

- Feeler gauges for measuring valve clearances.

- Grinding tools for reconditioning valve seats.

- Precision straightedge and feeler gauges for checking head warpage.

Q: What should I check when inspecting rocker arms?

- Look for wear on the contact surface where the arm meets the valve stem.

- Inspect the pivot points for wear or excessive play.

- Verify alignment to ensure proper operation.

Q: How is cylinder head warpage measured?

- Use a precision straightedge and feeler gauges.

- Lay the straightedge across the surface of the head and measure gaps at multiple points.

- If warpage exceeds the manufacturer’s limits, resurface or replace the cylinder head.

Q: What causes premature valve wear?

- Insufficient lubrication due to clogged oil passages or low oil levels.

- Incorrect valve lash adjustment.

- Use of poor-quality fuel leading to carbon buildup.

- Overheating caused by improper cooling system maintenance.

Q: What steps should I take during reassembly of the cylinder head?

- Clean all parts and inspect for wear or damage.

- Install new valve seals and guide inserts as necessary.

- Assemble the valves, springs, and retainers, ensuring correct alignment and seating.

- Position the cylinder head on the block with a new gasket.

- Tighten bolts in the recommended sequence and torque them to specifications.

Q: What should be done if valves are sticking or not sealing properly?

- Remove the valves and clean the stems and guides.

- Check the guide clearance and replace worn guides.

- Regrind the valve face and seat for proper sealing.

- Use high-quality lubricants during reassembly to ensure smooth operation.

Q: How do I know if valve seals need replacement?

- Blue smoke from the exhaust indicates oil is leaking past the seals into the combustion chamber.

- Excessive oil consumption without visible external leaks may point to worn valve seals.

Proper cylinder head and valve maintenance is critical for efficient engine operation and longevity. Regular inspections and timely repairs can prevent costly failures and keep your engine performing optimally.

Storage and Preservation

Q: How should the engine be stored long-term?

- Drain All Fluids: Remove oil, coolant, and fuel from the engine to prevent corrosion or contamination.

- Clean Thoroughly: Clean the engine exterior to remove dirt, grease, and grime.

- Apply Rust-Preventive Oil: Coat all exposed metal surfaces, including cylinder bores and valve train components, with a rust-preventive oil or fogging oil.

- Seal Openings: Cover or plug intake and exhaust openings, fuel lines, and other exposed ports to keep out dust, moisture, and pests.

- Protect the Engine: Use a high-quality cover to shield the engine from dust and moisture, ensuring it is stored in a dry and temperature-controlled environment.

Q: What additional steps should be taken for marine engines in storage?

- Flush the cooling system with fresh water and a corrosion inhibitor.

- Remove the propeller shaft and lubricate the bearings.

- Treat the fuel system with a stabilizer if fuel is left in the tank.

Q: What should be done before restarting a stored engine?

- Refill with Fresh Fluids: Replace all drained fluids, including oil, coolant, and fuel, with new, clean products.

- Inspect for Damage: Check for rust, corrosion, or physical damage that may have occurred during storage.

- Perform a System Check:

- Verify that all gaskets and seals are intact and replace any that show wear.

- Check the battery and electrical connections for proper charge and contact.

- Rotate the engine manually to ensure it moves freely without obstructions.

- Prime the Lubrication System: Before starting, crank the engine without fuel to circulate oil and prevent a dry start.

Q: How can fuel systems be preserved during long-term storage?

- Drain the fuel system entirely or treat the remaining fuel with a high-quality stabilizer.

- Clean the fuel tank to remove any sediment or water.

- Coat internal fuel lines and injectors with light oil to prevent rust.

Q: What should be done to the cooling system for storage?

- Drain the coolant and flush the system with fresh water.

- Refill with a mixture of water and antifreeze if temperatures may drop below freezing.

- Add a corrosion inhibitor to prevent rust and scale formation during storage.

Q: How can electrical components be protected during storage?

- Disconnect the battery and store it separately in a cool, dry place.

- Apply dielectric grease to electrical connectors to prevent corrosion.

- Inspect the wiring harness for cracks or wear and repair as needed.

Q: What should be done to prevent pests during storage?

- Plug all openings, such as intake manifolds and exhaust pipes, with moisture-proof materials.

- Use mothballs or pest deterrents around the storage area to keep rodents and insects away.

Q: How often should stored engines be inspected?

- Inspect stored engines every 1-3 months to ensure covers, seals, and plugs remain intact.

- Rotate the crankshaft manually to prevent internal components from seizing.

- Check for any signs of rust, leaks, or pest infestation.

Q: What are signs that the engine was improperly stored?

- Rust or Corrosion: Indicates insufficient use of protective coatings or inadequate sealing.

- Hard Starting or Sticking: Suggests dried or contaminated lubrication in moving parts.

- Leaking Gaskets or Seals: Points to seal degradation caused by improper preparation or fluctuating storage conditions.

Q: How should engines be prepared for seasonal storage?

- Perform a full oil and filter change before storage to remove contaminants.

- Add a fuel stabilizer to prevent fuel degradation during shorter storage periods.

- Remove the battery and charge it periodically during the off-season.

Q: What steps should be taken for engines stored outdoors?

- Use a weather-resistant cover designed for the engine to shield it from rain and UV exposure.

- Elevate the engine off the ground to avoid direct contact with moisture.

- Inspect covers and seals more frequently to ensure no moisture enters the system.

Q: How can engines be preserved for extreme environments?

- Use high-quality protective coatings and greases that withstand temperature fluctuations and high humidity.

- Store the engine in an airtight, climate-controlled enclosure if possible.

- Add desiccant packs around the engine to absorb moisture in extremely humid environments.

Q: What should be done if the engine fails to start after storage?

- Verify that all fluids have been replaced and are at the proper levels.

- Check the battery and electrical connections for corrosion or insufficient charge.

- Inspect the fuel system for clogs or airlocks caused by residual fuel.

- Perform a compression test to rule out internal damage or stuck valves.

Q: How can engine longevity be ensured after storage?

- Gradually run the engine under light load to reseat components and allow fluids to circulate properly.

- Replace any seals, gaskets, or hoses that show wear or have degraded during storage.

- Follow regular maintenance schedules immediately after putting the engine back into service.

By following these storage and preservation guidelines, you can minimize risks and ensure your Detroit Diesel V-71 engine remains in optimal condition for future use.

Additional Resources

Q: Are detailed specifications and tolerances available?

Yes, Diesel Pro Power’s blog includes extensive technical specifications, clearances, and tolerances for Detroit Diesel V-71 engines.

Q: How can I find specific topics or parts for my engine?

Visit Diesel Pro Power’s website for categorized resources, parts catalogs, and detailed blog posts tailored to the V-71 series.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588