Introduction

The cooling system of any diesel engine plays a critical role in ensuring efficient operation, longevity, and fuel economy. The Cummins QSC 8.3 and QSL 9 engines are high-performance engines that operate under extreme loads in marine, industrial, agricultural, and construction environments. These engines generate high amounts of heat, and without a properly maintained cooling system, they are at risk of overheating, thermal stress, and internal damage.

A faulty or poorly maintained cooling system can cause major engine failures, including warped cylinder heads, blown head gaskets, cracked blocks, and loss of power. Routine cooling system inspections, fluid replacements, and component maintenance are essential to preventing costly repairs and downtime.

This guide covers the importance of cooling system maintenance, radiator and coolant servicing, water pump inspection and replacement, common cooling system failures, and troubleshooting steps for Cummins QSC 8.3 and QSL 9 engines.

Fresh Water Pump & Related Components for Cummins QSC Engine

Fresh Water Pump & Related Components for Cummins QSL Engine

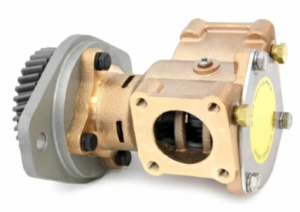

Marine Water Pump & Related Components for Cummins QSC Engine

Marine Water Pump & Related Components for Cummins QSL Engine

1. Importance of Maintaining Proper Cooling

Diesel engines operate at high combustion temperatures, often exceeding 1,100 degrees Fahrenheit in the combustion chamber. The cooling system plays a vital role in preventing the engine from reaching dangerously high temperatures by circulating coolant through the engine block, cylinder head, turbocharger, and radiator.

1.1 The Role of the Cooling System in Engine Health

A properly functioning cooling system removes excess heat and ensures that the engine operates within its optimal temperature range, which is typically 180-200 degrees Fahrenheit for Cummins QSC 8.3 and QSL 9 engines.

A malfunctioning cooling system can result in:

- Overheating, leading to gasket failure, piston seizure, and cracked components

- Coolant contamination, causing corrosion and reduced cooling efficiency

- Reduced fuel economy, as overheated engines burn fuel less efficiently

- Thermal expansion and contraction, which causes premature wear on metal components

- Complete engine failure, requiring an expensive overhaul or replacement

1.2 Signs of Cooling System Problems

Recognizing early signs of cooling system issues can prevent severe engine damage. Common symptoms include:

- Rising engine temperature gauge

- Coolant leaks under the engine

- Discolored or dirty coolant

- Loss of coolant without visible leaks

- Steam coming from the radiator or coolant reservoir

- Sweet smell from burning coolant

- Low coolant warning light on the dashboard

Ignoring these warning signs can lead to major mechanical failures. Regular maintenance and inspections can prevent these problems.

2. Radiator and Coolant Maintenance

The radiator and coolant system must be properly maintained to prevent overheating, corrosion, and leaks. Over time, coolant can become contaminated with debris, rust, and air bubbles, reducing its effectiveness. Similarly, radiators can become clogged or damaged, leading to inefficient heat dissipation.

2.1 Radiator Maintenance and Inspection

The radiator is one of the most important components in the cooling system. It allows heat from the engine to dissipate into the atmosphere through its cooling fins and core. Regular maintenance is required to ensure proper airflow and heat transfer.

Steps for Radiator Inspection and Maintenance

- Check for Leaks

- Inspect the radiator for signs of coolant leakage, especially around the seams, hoses, and fittings.

- Use a pressure tester to check for internal leaks that may not be visible.

- Clean Radiator Fins

- Dirt, dust, and debris can accumulate in the radiator fins, reducing cooling efficiency.

- Use compressed air or a low-pressure water hose to clean debris from the fins.

- Check Radiator Cap and Pressure Rating

- A faulty radiator cap can cause coolant loss and overheating.

- Ensure the cap maintains the correct system pressure, which is typically 7-15 psi depending on the application.

- Flush the Radiator Regularly

- Coolant degrades over time, leading to rust and corrosion buildup in the radiator.

- Perform a coolant flush every 1,000 hours or annually to remove contaminants.

- Check Radiator Hoses

- Inspect hoses for cracks, leaks, or swelling, as weak hoses can rupture under pressure.

- Replace any damaged hoses to prevent leaks.

2.2 Coolant Maintenance and Replacement

Coolant plays a dual role in the cooling system by absorbing heat and preventing internal corrosion. Using the right coolant type and maintaining it at proper levels ensures optimal engine performance.

Types of Coolant Recommended for Cummins QSC 8.3 and QSL 9

- Ethylene glycol-based extended-life coolant (ELC)

- 50/50 premixed antifreeze with distilled water

- Heavy-duty diesel coolant with corrosion inhibitors

Never mix different coolant types, as this can lead to chemical reactions that reduce cooling effectiveness and form sludge inside the radiator.

Coolant Change Intervals

- Replace coolant every 1,000 hours or as recommended by Cummins.

- Use a coolant test strip to check for pH balance and contamination every 250 hours.

- Inspect coolant condition visually for discoloration, foam, or oil contamination.

Proper Coolant Mixture

- For normal conditions: 50/50 coolant-to-water ratio

- For extreme cold: 60/40 or 70/30 coolant-to-water ratio

Proper coolant mixture prevents freezing in cold climates and overheating in hot environments.

3. Water Pump Inspection and Replacement

The water pump is responsible for circulating coolant through the engine, radiator, and heat exchangers. A failing water pump can lead to poor cooling performance and engine overheating.

3.1 Signs of a Failing Water Pump

- Coolant leaks from the water pump housing

- Engine overheating despite a full coolant level

- Grinding or squealing noises from the pump bearings

- Corrosion or rust buildup on the pump body

- Coolant not circulating properly

A failing water pump must be replaced immediately to prevent catastrophic engine damage.

3.2 Water Pump Replacement Procedure

If the water pump is faulty, follow these steps for replacement:

Steps to Remove and Replace the Water Pump

- Drain the Coolant

- Open the radiator drain valve and fully remove the coolant.

- Open the radiator drain valve and fully remove the coolant.

- Disconnect Hoses and Mounting Bolts

- Remove coolant hoses connected to the pump.

- Loosen and remove mounting bolts.

- Remove the Old Water Pump

- Gently pry the old pump from the housing.

- Clean any gasket residue from the engine block.

- Install the New Water Pump

- Apply sealant or a new gasket to the pump mating surface.

- Torque mounting bolts to Cummins specifications.

- Reconnect Hoses and Refill Coolant

- Ensure hoses are securely clamped.

- Refill with new coolant mixture.

- Bleed Air from the System

- Run the engine at idle with the radiator cap off until air bubbles stop escaping.

- Run the engine at idle with the radiator cap off until air bubbles stop escaping.

- Check for Leaks and Proper Operation

- Monitor temperature gauge for normal operation.

- Monitor temperature gauge for normal operation.

4. Common Cooling System Problems and Troubleshooting

Overheating Despite Coolant Being Full

- Possible Cause: Thermostat stuck closed.

- Solution: Replace the thermostat.

Coolant Leaks Near the Engine

- Possible Cause: Water pump seal failure.

- Solution: Inspect and replace the pump if necessary.

White Smoke from Exhaust with Coolant Loss

- Possible Cause: Blown head gasket.

- Solution: Perform a coolant pressure test and inspect the cylinder head.

Coolant Turning Brown or Sludgy

- Possible Cause: Mixing different coolant types.

- Solution: Flush the system and use manufacturer-recommended coolant.

Conclusion

Proper cooling system maintenance is essential for ensuring long-term performance, efficiency, and durability of Cummins QSC 8.3 and QSL 9 engines. Routine radiator inspections, coolant management, and water pump servicingprevent overheating, corrosion, and major engine failures.

For OEM-quality aftermarket cooling components, maintenance kits, and expert advice, visit Diesel Pro Power for high-performance solutions.

Fresh Water Pump & Related Components for Cummins QSC Engine

Fresh Water Pump & Related Components for Cummins QSL Engine

Marine Water Pump & Related Components for Cummins QSC Engine

Marine Water Pump & Related Components for Cummins QSL Engine

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588