The Importance of Torquing Cylinder Head Bolts to OEM Specifications on the Cummins 6CTA 8.3L Marine Engine

The Cummins 6CTA 8.3L marine diesel engine is known for its reliability, power density, and long service life. Found in commercial vessels, sportfishing boats, patrol craft, and workboats around the world, the 6CTA 8.3 delivers strong torque, efficient fuel burn, and exceptional performance even under sustained load. However, the durability of this engine depends on one critical procedure during maintenance and overhaul: properly torquing the cylinder head bolts to OEM specifications.

Incorrect torque values, improper tightening sequence, or using non-OEM torque procedures can lead to catastrophic problems — from head gasket failure and coolant leaks to cylinder distortion, premature wear, or total engine meltdown. In marine environments, where engines operate at high load for long periods and failures at sea pose safety risks, following the Cummins torque specifications isn’t optional. It is essential.

This article explores why proper torque matters, how it affects engine performance, what happens when torque procedures are ignored, and why technicians must always follow OEM guidelines when servicing the 6CTA 8.3L marine engine.

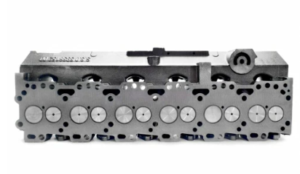

Shop Cylinder Heads & Related Components For The Cummins 6CTA 8.3L

Understanding the Role of Cylinder Head Bolts in the Cummins 6CTA 8.3L

The cylinder head bolts form the critical structural connection between the cylinder block and the cylinder head. Their job is far more complex than simply “holding the head on.”

Under operation, combustion chamber pressures inside the cylinders can exceed 2,000 psi, creating extreme forces that push upward on the cylinder head while simultaneously compressing the gasket. The head bolts must provide the exact clamping load required to:

- Maintain gasket sealing under boost

- Resist lateral and vertical head movement

- Prevent compression leakage

- Keep coolant and oil passages sealed

- Maintain uniform head-to-block contact across all cylinders

In a marine environment, the 6CTA 8.3 often operates close to continuous rated power, meaning the head bolts experience high thermal loads, sustained combustion pressure, and heavy structural strain for long periods. Correct torque is the only way to ensure these forces remain under control.

Shop Cylinder Head Bolts For The Cummins 6CTA 8.3L

Why OEM Torque Specifications Matter

Cylinder head bolt torque specifications are not arbitrary numbers. Cummins engineers determine torque values through extensive testing, accounting for:

- Bolt material strength

- Bolt stretch characteristics

- Thermal expansion of block and head

- Head gasket compression behavior

- Engine operating temperature

- Combustion pressure and boost levels

- Shear, tensile, and clamping force calculations

If the head bolts are torqued outside factory specifications, even by a small margin, the engineered clamping balance across the head surface is compromised. This puts the engine at significant risk.

Torque Too Low → Insufficient Clamping

Under-torquing cylinder head bolts leads to:

- Head gasket leaks

- Compression loss

- Hot spots between cylinders

- Coolant intrusion into cylinders

- Exhaust gases entering the cooling system

- Premature head gasket failure

- Misalignment between the head and block

Even minor under-torque (5–10%) can produce measurable sealing issues under high cylinder pressures.

Torque Too High → Excessive Stress and Distortion

Over-torquing head bolts causes:

- Bolt stretching beyond the yield point

- Thread damage in the block

- Cylinder head warping

- Cracked cylinder heads

- Crushed gasket layers

- Uneven sealing load

- Premature head gasket blowout under load

Over-torque is especially dangerous because bolt stretch may not be immediately visible — but structural damage accumulates over time until a catastrophic failure occurs.

Incorrect Tightening Sequence → Uneven Head Seating

Even if torque numbers are correct, tightening the bolts in the wrong order can:

- Warp the cylinder head

- Create uneven clamping force

- Cause distortion around combustion chambers

- Reduce head gasket life

- Allow micro-leaks that grow over time

Cummins provides a very specific tightening pattern to ensure the head seats progressively and evenly. Deviating from that sequence is a direct path to gasket failure.

Why Torquing Matters Even More in Marine Applications

Marine engines do not operate like automotive engines. The Cummins 6CTA 8.3L marine engine often runs:

- At high RPM for long stretches

- Under heavy continuous load

- In high humidity and saltwater environments

- With limited airflow compared to land-based engines

- At stable, elevated temperatures for long durations

These conditions amplify the consequences of improper cylinder head bolt torque.

Continuous Load Amplifies Thermal Expansion

When a marine engine is heavily loaded for hours, the head and block expand and contract repeatedly. If bolts lack the correct stretch and preload, this thermal cycling loosens clamping force and leads to leaks or gasket failure.

Turbocharged Marine Engines Experience Higher Cylinder Pressure

The 6CTA 8.3L marine variants often run higher boost and higher fueling rates than land-based versions. Higher cylinder pressure requires perfect sealing integrity—something only possible when head bolts are torqued exactly to spec.

Saltwater Adds Corrosion Risk

Saltwater exposure accelerates corrosion around the head gasket, bolt threads, and mating surfaces. Proper torque ensures maximum surface compression, reducing pathways for corrosion to spread.

Marine Engine Failures Are More Dangerous

A blown head gasket offshore is far more than an inconvenience — it can lead to:

- Loss of propulsion

- Overheating

- Coolant flooding the bilge

- Crankcase pressurization

- Engine seizure

Having reliable head gasket sealing isn’t simply about performance; it’s a critical safety requirement.

Bolt Stretch: The Hidden Factor Many Technicians Ignore

Cylinder head torque isn’t just about the rotating force applied to the bolt. It’s about achieving the correct amount of bolt stretch.

Cummins head bolts are engineered to stretch a precise distance during tightening. Stretch creates:

- Elastic clamping force

- Thermal compensation for expansion

- Even distribution of load

- Continuous sealing pressure throughout engine operation

If torque is too low, bolts never reach the required elongation.

If torque is too high, bolts exceed the yield point and never return to their original length.

Either condition destroys sealing integrity.

OEM torque specs ensure bolts stretch exactly as designed.

Using Aftermarket Torque Values or Guessing Is Dangerous

Some technicians attempt to “tighten a little extra” or use outdated torque sheets from other engine families. Others guess based on experience, or use impact tools — a major mistake.

Failure to use Cummins OEM torque values may result in:

- Immediate head gasket failure under load

- Block thread damage

- Cracked cylinder heads

- Uneven surface clamping

- Overstressed bolts that fail in operation

- A total engine teardown

Marine engines are unforgiving. Taking shortcuts during head bolt torquing always shows up later — usually as a very expensive failure.

Other Factors That Affect Proper Torque

Correct torque is not simply a matter of turning a wrench to the right number. Several conditions must be met:

Lubrication of bolt threads

OEM specifications account for friction. Dry bolts produce incorrect torque readings.

Surface cleanliness

Any debris on mating surfaces reduces clamping force.

Condition of bolt threads

Damaged threads alter torque resistance and reduce bolt stretch accuracy.

Tool calibration

Torque wrenches must be certified and calibrated.

Bolt replacement when required

Some bolts should never be reused if stretched beyond spec.

Neglecting these factors upsets the torque process, even when the technician thinks the correct number was used.

Head Gasket Performance Depends Entirely on Proper Torque

The head gasket on a Cummins 6CTA 8.3L is designed to compress to a precise thickness. This compression affects:

- Combustion sealing

- Coolant passage sealing

- Oil passage sealing

- Alignment of the head to the block

- Heat transfer between components

- Gasket lifespan

If bolt torque is incorrect, the gasket cannot achieve its engineered compression level. In marine environments with continuous high load, this becomes a failure waiting to happen.

Conclusion: OEM Torque Procedures Protect Your Engine and Your Vessel

The Cummins 6CTA 8.3L marine diesel is a powerful, durable engine, but it relies heavily on the integrity of its cylinder head clamping system. Properly torqued cylinder head bolts — tightened exactly to OEM specifications and in the correct sequence — are essential for:

- Leak-free operation

- Engine performance

- Safety at sea

- Long-term reliability

- Avoiding catastrophic failures

Marine engines demand more precision, not less. By following Cummins specifications and performing torquing procedures exactly as engineered, mechanics and vessel owners ensure the 6CTA 8.3L delivers the reliability that Cummins is known for across thousands of hours of service.

Shop Cylinder Heads & Related Components For The Cummins 6CTA 8.3L

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588