Introduction

Diesel engines have been at the heart of industrial, marine, and heavy-duty applications for decades. Among the most trusted names in diesel power is Cummins, a company known for producing some of the most reliable and efficient engines in the world. Two standout models in Cummins’ lineup are the QSC 8.3 and QSL 9 engines. These engines are the backbone of many marine vessels, construction equipment, heavy trucks, and agricultural machinery.

For engine owners, operators, and mechanics, understanding the maintenance, troubleshooting, and repair procedures for these engines is essential. Regular maintenance is not just about ensuring the engine runs—it’s about optimizing performance, maximizing efficiency, and preventing costly repairs down the line.

This guide provides an in-depth overview of the Cummins QSC 8.3 and QSL 9, covering their technical specifications, applications, common issues, and best practices for maintaining peak performance.

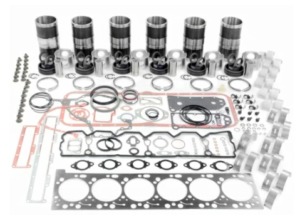

Parts Catalog for QSC 8.3 Cummins Marine and Industrial Engines

Parts Catalog for QSL 9 Cummins Marine and Industrial Engines

Understanding the Cummins QSC 8.3 and QSL 9 Engines

Cummins QSC 8.3 Overview

The Cummins QSC 8.3 is an electronically controlled diesel engine with a displacement of 8.3 liters (506 cubic inches). It evolved from the 6CTA 8.3 but was upgraded with full-authority electronic fuel injection, making it more efficient and compliant with emissions standards.

Key Features of the QSC 8.3

- High-Pressure Common Rail (HPCR) Fuel System: Provides precise fuel control, improving efficiency and reducing emissions.

- Electronic Controls: Integrates with Cummins’ ECM (Engine Control Module) for better monitoring and diagnostics.

- Turbocharged and Aftercooled: Increases power output and fuel efficiency while reducing heat stress on components.

- Power Output: Typically between 300-600 HP, depending on the application.

- Lower Emissions: Complies with Tier 3 and Tier 4 Final emissions standards, depending on configuration.

Applications of the QSC 8.3

- Marine propulsion systems

- Construction equipment (excavators, loaders, cranes)

- Emergency generators

- Fire pump engines

- Agricultural machinery

Cummins QSL 9 Overview

The QSL 9 is an advanced 9.0-liter diesel engine designed for high-torque applications. It shares many of the same features as the QSC 8.3 but offers increased displacement and higher torque output, making it better suited for heavy-duty applications.

Key Features of the QSL 9

- More Displacement for More Power: At 9.0 liters, the engine delivers higher torque, making it ideal for heavy-duty industrial and commercial use.

- Advanced Fuel Injection System: The HPCR system ensures optimal fuel efficiency and performance.

- Heavy-Duty Cooling System: Enhanced cooling design allows the engine to operate at high loads for extended periods.

- Power Output: Typically ranges between 250-400 HP, with torque ratings that outperform the QSC 8.3.

- Durability: Features a stronger block and internal components, allowing it to handle more demanding applications.

Applications of the QSL 9

- Heavy-duty trucks

- Agricultural tractors and sprayers

- Oil and gas drilling rigs

- Industrial power generators

- Military vehicles

Importance of Regular Maintenance and Repairs

Maintaining a Cummins QSC 8.3 or QSL 9 engine requires a proactive approach. Diesel engines, especially those used in marine, industrial, and heavy-duty environments, operate under extreme conditions. Failing to follow a routine maintenance schedule can lead to expensive failures, increased fuel consumption, and downtime.

Benefits of Proper Maintenance

- Prevents Unexpected Failures – Catching minor issues early prevents catastrophic engine failure.

- Improves Fuel Efficiency – A well-maintained engine burns fuel more efficiently, reducing operational costs.

- Reduces Downtime – Regular inspections and servicing minimize the chances of unexpected breakdowns.

- Extends Engine Life – Routine oil changes, filter replacements, and component inspections keep the engine running longer.

- Ensures Regulatory Compliance – Proper maintenance ensures compliance with EPA emissions regulations.

Recommended Maintenance Schedule for Cummins QSC 8.3 and QSL 9

Daily Maintenance Checks

- Check engine oil level and refill if necessary.

- Inspect coolant level and top off as needed.

- Check fuel levels and look for leaks in the fuel system.

- Inspect for leaks in hoses, connections, and fittings.

- Monitor engine performance for any unusual noises or vibrations.

Every 250 Hours (or Monthly)

- Change engine oil and replace the oil filter.

- Inspect and clean air filters.

- Check fuel filter and replace if needed.

- Inspect all belts and pulleys for signs of wear.

- Check battery voltage and terminals for corrosion.

Every 500 Hours (or Quarterly)

- Flush and replace coolant.

- Perform a fuel system inspection, including the injectors and pump.

- Inspect turbocharger and clean as necessary.

- Lubricate all moving parts.

Every 1,000 Hours (or Annually)

- Adjust valve clearance.

- Inspect and replace engine mounts.

- Perform compression testing to evaluate engine health.

- Inspect ECM diagnostics and update firmware if necessary.

Every 2,000 Hours (or Bi-Annually)

- Replace the water pump.

- Inspect and service exhaust system.

- Perform a complete electrical system check.

Common Issues and Troubleshooting for QSC 8.3 & QSL 9 Engines

Despite their rugged build, these engines can develop issues over time. Understanding common problems and their solutions can prevent major failures.

1. Fuel System Problems

Symptoms:

- Hard starting or failure to start

- Loss of power

- Excessive black smoke

Causes:

- Clogged fuel filters

- Air in fuel lines

- Injector wear

Solution:

- Replace fuel filters regularly.

- Bleed air from the fuel system.

- Inspect and replace fuel injectors.

Fuel Filter & Related Components for Cummins QSC Engine

Fuel Filter & Related Components for Cummins QSL Engine

2. Overheating Issues

Symptoms:

- High temperature readings

- Loss of coolant

- Reduced performance

Causes:

- Low coolant levels

- Clogged radiator

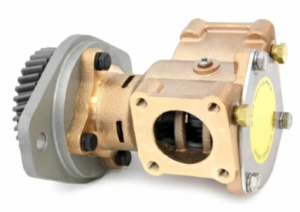

- Failing water pump

Solution:

- Regularly flush and refill coolant.

- Clean radiator fins and check for blockages.

- Replace faulty water pumps.

Fresh Water Pump & Related Components for Cummins QSC Engine

Fresh Water Pump & Related Components for Cummins QSL Engine

Marine Water Pump & Related Components for Cummins QSC Engine

Marine Water Pump & Related Components for Cummins QSL Engine

3. Oil Leaks

Symptoms:

- Visible oil drips

- Low oil pressure warning

Causes:

- Worn-out gaskets and seals

- Loose oil pan bolts

Solution:

- Tighten bolts to proper torque specifications.

- Replace worn-out seals and gaskets.

Lubrication system & Related Components for Cummins QSC Engine

Lubrication system & Related Components for Cummins QSL Engine

Performance Optimization Tips

- Use Premium Diesel Fuel – Prevents injector clogging and maintains performance.

- Monitor ECM Data – Regular engine diagnostics help detect early issues.

- Keep Turbocharger Clean – A clean turbo boosts power output and efficiency.

- Use High-Quality Oil and Filters – Extends engine life and prevents sludge buildup.

- Follow Proper Warm-Up and Cool-Down Procedures – Extends turbo and engine life.

Conclusion

The Cummins QSC 8.3 and QSL 9 engines are built for performance, reliability, and efficiency. However, proper maintenance is crucial to ensure longevity and peak performance. By following a routine maintenance schedule, addressing common troubleshooting issues, and implementing performance optimizations, you can extend engine lifeand avoid costly repairs.

For aftermarket replacement parts, maintenance kits, and expert advice, visit Diesel Pro Power for high-quality Cummins engine components.

Parts Catalog for QSC 8.3 Cummins Marine and Industrial Engines

Parts Catalog for QSL 9 Cummins Marine and Industrial Engines

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588