Introduction

The Cummins QSL 9 engine is a powerful and reliable 9-liter diesel engine widely used in marine, industrial, agricultural, and construction applications. While it boasts durability and high performance, like any engine, it is not without its challenges. Understanding common Cummins QSL 9 problems and their solutions can help operators avoid downtime, reduce repair costs, and extend the lifespan of their engines.

In this article, we will cover the most common issues with the Cummins QSL 9, potential causes, troubleshooting methods, and maintenance tips to keep your engine running smoothly.

Parts Catalog for QSL 9 Cummins Marine and Industrial Engines

Summary

This article explores the most common issues with the Cummins QSL 9 engine and provides practical solutions. Key points covered include:

- Fuel System Problems

- Overheating Issues

- Turbocharger Problems

- EGR System Issues

- Crankshaft Position Sensor Failure

- Electrical Problems

- Cylinder Head Gasket Failure

- DPF Clogging

- Oil Leaks

- Preventive Maintenance

1. Fuel System Problems

Symptoms:

- Engine misfire or hesitation

- Difficulty starting

- Reduced fuel efficiency

- Black or white smoke from the exhaust

Causes:

- Injector failure: Over time, fuel injectors may become clogged or wear out, causing uneven fuel delivery.

- Fuel contamination: Water or debris in the fuel can clog filters and damage injectors.

- Low fuel pressure: A failing fuel pump or restricted fuel lines can reduce fuel pressure, leading to poor engine performance.

- Faulty fuel lift pump: The lift pump assists in delivering fuel from the tank to the high-pressure pump. A failing lift pump can result in fuel starvation.

Solutions:

- Replace clogged or faulty injectors with high-quality replacements.

- Drain water from the fuel-water separator regularly.

- Use clean, high-quality diesel fuel to prevent contamination.

- Inspect and replace the fuel pump if pressure is below specifications.

- Change fuel filters at recommended intervals.

Fuel Pump & Related Components for Cummins QSL9 Marine engine

2. Overheating Issues

Symptoms:

- Engine temperature gauge reading high

- Coolant loss

- Steam from the radiator or engine compartment

Causes:

- Coolant leaks: Leaks from hoses, radiator, or head gasket can lead to overheating.

- Thermostat failure: A stuck thermostat can prevent proper coolant flow.

- Clogged radiator: A dirty or blocked radiator reduces cooling efficiency.

- Water pump failure: A worn-out water pump can hinder coolant circulation.

Solutions:

- Inspect the coolant system for leaks and repair as necessary.

- Flush the radiator and refill with fresh coolant per manufacturer specifications.

- Replace a faulty thermostat to restore proper temperature regulation.

- Check the water pump and replace it if there are signs of wear or failure.

Freshwater Pump & Related Components for Cummins QSL9 Marine engine

Raw water Pump & Related Components for Cummins QSL9 Marine engine

3. Turbocharger Problems

Symptoms:

- Loss of power

- Excessive black smoke

- Whining noise from the turbo

- Oil leaking into the intake

Causes:

- Oil contamination: Dirty or degraded oil can damage turbo bearings.

- Clogged or damaged intercooler: A restricted intercooler can lead to high intake temperatures and reduced performance.

- Boost leaks: Cracks or loose clamps in the charge air system can cause power loss.

- Worn turbocharger: Excessive wear on the turbo can reduce its efficiency.

Solutions:

- Regularly change engine oil and use high-quality lubricants.

- Inspect and clean the intercooler to prevent clogging.

- Check for leaks in the charge air system and repair damaged hoses or clamps.

- Replace the turbocharger if excessive wear is found.

Turbocharger & Related Components for Cummins QSL9 Marine engine

4. EGR (Exhaust Gas Recirculation) System Issues

Symptoms:

- Rough idling

- Reduced power output

- Check engine light (CEL) illuminated

- Increased emissions

Causes:

- Carbon buildup: Over time, soot and carbon can clog the EGR valve, reducing performance.

- Stuck EGR valve: If the valve sticks open or closed, it can affect combustion.

- EGR cooler failure: A leaking EGR cooler can lead to coolant loss and white smoke.

Solutions:

- Clean or replace the EGR valve to remove carbon buildup.

- Inspect and replace the EGR cooler if leaking.

- Use ultra-low sulfur diesel (ULSD) fuel to minimize carbon deposits.

5. Crankshaft Position Sensor Failure

Symptoms:

- Engine stalling or failure to start

- Erratic RPM readings

- Loss of power

Causes:

- Sensor wear: Over time, the sensor may degrade and fail to send accurate signals.

- Wiring issues: Corrosion or damaged wiring can disrupt sensor communication.

Solutions:

- Replace the crankshaft position sensor with an OEM or high-quality aftermarket part.

- Check wiring connections and repair or replace damaged wires.

Crankshaft & Related Components for Cummins QSL9 Marine engine

6. Electrical Problems

Symptoms:

- Dash warning lights flickering

- Intermittent starting issues

- Loss of communication between engine components

Causes:

- Loose or corroded battery terminals

- Faulty alternator

- Wiring harness damage

Solutions:

- Clean battery terminals and ensure tight connections.

- Test the alternator and replace if output is insufficient.

- Inspect and repair damaged wiring.

Starter & Related Components for Cummins QSL9 Marine engine

7. Cylinder Head Gasket Failure

Symptoms:

- White smoke from exhaust

- Coolant mixing with engine oil

- Loss of compression

Causes:

- Overheating: Persistent overheating can cause the gasket to fail.

- Improper torque on head bolts: Incorrect installation can lead to premature failure.

Solutions:

- Replace the head gasket and ensure bolts are torqued to specifications.

- Address any cooling system issues to prevent recurrence.

Cylinder Head & Related Components for Cummins QSL9 Marine engine

8. DPF (Diesel Particulate Filter) Clogging

Symptoms:

- Check engine light (CEL) illuminated

- Reduced power

- Increased fuel consumption

Causes:

- Short drive cycles: Frequent short trips prevent the DPF from regenerating properly.

- Excessive soot buildup: Poor combustion or excessive idling can clog the DPF.

Solutions:

- Perform forced regeneration via a diagnostic tool if clogging occurs.

- Drive the vehicle at highway speeds periodically to allow passive regeneration.

- Use high-quality diesel fuel and DEF fluid to reduce soot production.

9. Oil Leaks

Symptoms:

- Oil puddles under the engine

- Low oil levels

- Engine smoking

Causes:

- Worn gaskets or seals

- Cracked oil pan

- Turbocharger leaks

Solutions:

- Replace worn-out seals and gaskets.

- Inspect the oil pan and repair or replace if cracked.

- Address turbo oil leaks promptly.

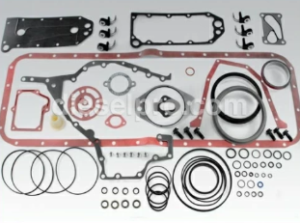

Gaskets & Related Components for Cummins QSL9 Marine engine

Preventative Maintenance for the Cummins QSL 9

To minimize these common problems, follow these preventative maintenance tips:

- Use high-quality fuel and lubricants to prevent carbon buildup and wear.

- Change the oil and filters at the manufacturer’s recommended intervals.

- Inspect coolant and replace as needed to prevent overheating issues.

- Monitor turbocharger performance and replace if needed.

- Ensure the EGR and DPF systems are clean to reduce emissions-related failures.

- Check for leaks regularly and repair them immediately.

Conclusion

The Cummins QSL 9 engine is a reliable powerhouse, but knowing its common problems can help owners avoid costly repairs and downtime. Regular maintenance, early diagnosis, and timely repairs are essential for keeping your engine running at peak performance.

By understanding these Cummins QSL 9 problems and their solutions, operators can maximize efficiency, extend engine life, and reduce repair costs. If you suspect any of these issues with your engine, it’s best to address them quickly to prevent further damage.

Parts Catalog for QSL 9 Cummins Marine and Industrial Engines

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588