Performing daily maintenance on Detroit Diesel 92 Series engines is critical to ensuring reliable performance and avoiding unexpected failures. These steps provide a thorough, proactive approach to identifying and addressing potential issues before operation begins. Following these guidelines will help extend the life of your engine and optimize its efficiency.

Parts Catalog for 6V92 Detroit Deisel Engines

Parts Catalog for 8V92 Detroit Deisel Engines

Parts Catalog for 12V92 Detroit Deisel Engines

Parts Catalog for 16V92 Detroit Deisel Engines

Visual Inspection

A comprehensive visual inspection can reveal early signs of wear, damage, or potential failures.

-

Leaks

- Areas to Inspect:

- Examine hoses, seals, and gaskets for oil, coolant, or fuel leaks.

- Why It Matters:

- Early detection of leaks prevents fluid loss, contamination, and possible damage to nearby components.

- Early detection of leaks prevents fluid loss, contamination, and possible damage to nearby components.

- Areas to Inspect:

-

Loose Connections

- Inspection Points:

- Check fasteners, clamps, and connections for looseness or improper alignment.

- Potential Risks:

- Loose components can lead to vibrations, misalignment, or system failures.

- Loose components can lead to vibrations, misalignment, or system failures.

- Inspection Points:

-

Belts and Hoses

- What to Look For:

- Cracks, fraying, bulges, or wear on belts and hoses.

- Cracks, fraying, bulges, or wear on belts and hoses.

- Action Steps:

- Replace any worn or damaged components immediately to avoid operational issues or downtime.

- Replace any worn or damaged components immediately to avoid operational issues or downtime.

- What to Look For:

Fluid Levels

Monitoring and maintaining fluid levels is essential for lubrication, cooling, and combustion efficiency.

-

Engine Oil

![Oil Pump for Detroit Diesel 6V92 and 8V92 - [Right hand]](http://dieselpro.com/blog/content/uploads/2024/11/Screenshot-2025-02-19-052207-300x219.png)

Oil Pump for Detroit Diesel 6V92 and 8V92 – [Right hand]

- Steps:

- Use the dipstick to verify the oil level is within the recommended range.

- Top off with the correct grade of oil if necessary.

- Why It’s Important:

- Insufficient oil can lead to increased friction, overheating, and potential engine damage.

- Insufficient oil can lead to increased friction, overheating, and potential engine damage.

- Steps:

-

Coolant

![Water Pump for Detroit Diesel 6V92 and 8V92[Right Hand]](http://dieselpro.com/blog/content/uploads/2024/11/Screenshot-2025-02-19-052453-300x228.png)

Water Pump for Detroit Diesel 6V92 and 8V92[Right Hand]

- Steps:

- Check coolant levels in the reservoir or radiator and ensure the proper antifreeze mixture is used.

- Top off as needed, ensuring caps are tightly sealed.

- Common Issues:

- Low coolant levels can cause overheating, while improper mixtures can reduce corrosion protection.

- Low coolant levels can cause overheating, while improper mixtures can reduce corrosion protection.

- Steps:

-

Fuel

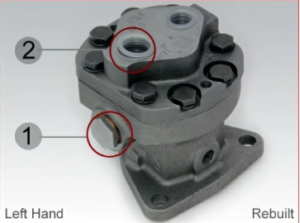

Fuel Pump for Detroit Diesel 8V92 Non-Turbo – [Left-Hand]

- Steps:

- Inspect the fuel level in the tank, ensuring it is sufficient for the operation.

- Check for signs of water contamination in the fuel-water separator.

- Key Consideration:

- Running low on fuel can introduce air into the system, leading to hard starts or performance issues.

- Running low on fuel can introduce air into the system, leading to hard starts or performance issues.

- Steps:

-

Cap and Plug Security

Detroit Diesel Head Plug Kit for , 6V92, 8V92

- Why It Matters:

- Loose caps or plugs can result in fluid leaks and contamination.

- Loose caps or plugs can result in fluid leaks and contamination.

- Why It Matters:

Air Intake System

A clean and unobstructed air intake system is essential for efficient combustion and optimal engine performance.

-

Air Filter

Detroit Diesel Air cleaner for 6V92 Non- turbo

Airsep for Detroit Diesel 6V92, 8V92 dual or twin turbo

- Inspection Steps:

- Remove the air filter and inspect for dirt, debris, or blockages.

- Remove the air filter and inspect for dirt, debris, or blockages.

- Action Steps:

- Clean or replace the filter if it appears clogged or excessively dirty.

- Clean or replace the filter if it appears clogged or excessively dirty.

- Impact:

- A clean air filter ensures proper airflow, improving combustion efficiency and reducing emissions.

- A clean air filter ensures proper airflow, improving combustion efficiency and reducing emissions.

- Inspection Steps:

- Air Intake Ducts

- Inspection Points:

- Check ducts for alignment, cracks, or leaks.

- Check ducts for alignment, cracks, or leaks.

- Common Issues:

- Damaged or misaligned ducts can introduce unfiltered air, causing wear on internal components.

- Damaged or misaligned ducts can introduce unfiltered air, causing wear on internal components.

- Inspection Points:

Exhaust System

A properly functioning exhaust system is critical for removing combustion byproducts and maintaining engine efficiency.

-

Obstruction Check

- Steps:

- Inspect the exhaust system for any obstructions, such as debris or soot buildup.

- Inspect the exhaust system for any obstructions, such as debris or soot buildup.

- Why It Matters:

- Blockages can cause backpressure, reducing engine efficiency and increasing emissions.

- Blockages can cause backpressure, reducing engine efficiency and increasing emissions.

- Steps:

-

Leak Detection

- Inspection Points:

- Look for leaks around the exhaust manifold, gaskets, and connections.

- Look for leaks around the exhaust manifold, gaskets, and connections.

- Common Symptoms:

-

Excessive noise or visible emissions near the manifold may indicate leaks.

-

- Inspection Points:

-

Soot Buildup and Discoloration

- Signs to Watch For:

- Black soot or unusual discoloration in the exhaust outlet.

- Black soot or unusual discoloration in the exhaust outlet.

- Possible Causes:

- Overfueling, incomplete combustion, or air intake restrictions.

- Overfueling, incomplete combustion, or air intake restrictions.

- Signs to Watch For:

Best Practices for Daily Maintenance

-

Use a Checklist

- Create a standardized checklist to ensure all maintenance tasks are completed consistently.

- Create a standardized checklist to ensure all maintenance tasks are completed consistently.

- Document Findings

- Record any issues or irregularities during the inspection for follow-up and repairs.

- Record any issues or irregularities during the inspection for follow-up and repairs.

-

Address Issues Promptly

- Don’t delay addressing leaks, damaged components, or other problems identified during maintenance.

- Don’t delay addressing leaks, damaged components, or other problems identified during maintenance.

-

Train Personnel

- Ensure all operators and technicians are trained to perform daily maintenance tasks effectively.

- Ensure all operators and technicians are trained to perform daily maintenance tasks effectively.

Conclusion

Performing daily maintenance on Detroit Diesel 92 Series engines ensures reliability and efficiency while reducing the risk of unexpected failures. By focusing on visual inspections, fluid levels, the air intake system, and the exhaust system, operators can proactively identify and resolve potential issues, extending the life of these iconic engines and optimizing their performance. Make daily checks a non-negotiable part of your maintenance routine to keep your engine running at peak efficiency.

Parts Catalog for 6V92 Detroit Deisel Engines

Parts Catalog for 8V92 Detroit Deisel Engines

Parts Catalog for 12V92 Detroit Deisel Engines

Parts Catalog for 16V92 Detroit Deisel Engines

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588