Common Questions About Rebuild Kits and Overhaul Parts for Cummins KTA19

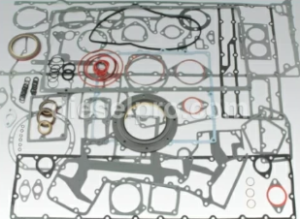

What is included in a Cummins KTA19 rebuild kit?

A Cummins KTA19 rebuild kit typically includes essential components needed to restore engine performance and reliability. These parts generally consist of pistons, piston rings, cylinder liners, main and rod bearings, gaskets, and seals. Some kits may also include additional components like thrust washers, camshaft bushings, and valve train parts, depending on the supplier and specific kit configuration.

What’s the difference between a rebuild kit and an overhaul kit?

While the terms “rebuild kit” and “overhaul kit” are often used interchangeably, there are key differences. A rebuild kit usually focuses on the core components needed to restore basic engine functionality, such as pistons, rings, liners, and gaskets. An overhaul kit often includes these items plus additional parts like fuel injectors, oil pumps, camshaft bushings, and valve components, providing a more comprehensive solution for engines undergoing extensive repairs.

Are aftermarket rebuild kits as reliable as OEM parts?

Yes, high-quality aftermarket rebuild kits can be just as reliable as OEM (Original Equipment Manufacturer) parts when sourced from reputable suppliers like Diesel Pro Power. These aftermarket kits are often manufactured to meet or even exceed OEM specifications, offering excellent performance and durability. The key is to ensure the parts are from trusted brands that have a proven track record for quality.

How do I know if I need a rebuild kit for my Cummins KTA19?

There are several signs that indicate the need for a rebuild kit for your Cummins KTA19. These include a loss of power, excessive oil consumption, poor fuel efficiency, and unusual engine noises such as knocking or rattling. Additionally, increased emissions, difficulty starting, or low compression readings during diagnostics are clear indicators that your engine may require a rebuild.

Can I rebuild a KTA19 engine myself?

Yes, you can rebuild a Cummins KTA19 engine yourself if you have mechanical experience, the right tools, and a thorough understanding of diesel engine systems. However, since the KTA19 is a complex, heavy-duty engine, the rebuild process can be challenging. For best results, consider professional assistance, especially for critical components like the fuel system, turbocharger, and camshaft alignment.

How often should a Cummins KTA19 be overhauled?

A Cummins KTA19 typically requires an overhaul every 15,000 to 20,000 operating hours, though this can vary based on operating conditions, maintenance practices, and load cycles. Engines operating under harsh conditions, such as marine environments or heavy industrial use, may require more frequent overhauls. Regular oil analysis, performance monitoring, and preventive maintenance can help determine the ideal overhaul schedule.

What tools are required for a KTA19 rebuild?

Rebuilding a KTA19 engine requires a range of specialized tools to ensure proper assembly and precision. Essential tools include torque wrenches, piston ring compressors, micrometers, dial bore gauges, and feeler gauges for measuring clearances. Additionally, you may need specialized Cummins service tools for tasks like camshaft timing, liner installation, and injector calibration.

How do I identify the correct rebuild kit for my KTA19?

To identify the correct rebuild kit for your KTA19, you’ll need the engine’s CPL (Control Parts List) number and engine serial number, both typically found on the dataplate attached to the engine block. These numbers help ensure compatibility with your engine’s specific configuration. Providing this information to a parts supplier like Diesel Pro Power ensures you receive the right components for your rebuild.

Do rebuild kits come with installation instructions?

Most rebuild kits do not come with detailed installation instructions. Instead, it’s recommended to refer to the official Cummins KTA19 service manual, which provides step-by-step procedures, torque specifications, and diagrams. Additionally, many suppliers and online platforms offer video tutorials and guides to assist with installation, especially for common procedures like piston installation, liner fitting, and timing adjustments.

Torque Specs for Cummins KTA19

Is it necessary to replace all components during an overhaul?

It’s not always necessary to replace every component during an engine overhaul. Parts such as connecting rods, camshafts, or crankshafts may be reused if they are within wear limits and free from damage. The decision to replace or reuse parts should be based on thorough inspection, measurements against OEM specifications, and service manual guidelines.

Can I mix OEM and aftermarket parts in a rebuild?

Yes, it is possible to mix OEM and aftermarket parts during a KTA19 rebuild as long as all components meet the required quality standards and specifications. It’s important to ensure that the aftermarket parts are compatible with OEM components to prevent performance issues. Working with a trusted supplier can help confirm compatibility across mixed-part rebuilds.

Aftermarket Parts Catalog for Cummins KTA19

What’s the average cost of a KTA19 rebuild kit?

The cost of a Cummins KTA19 rebuild kit varies based on the components included and the supplier. Factors like whether the kit includes major components such as injectors, turbochargers, or oil pumps can significantly impact the overall cost. To see the price of Dieselpro Power Overhaul Kits for Cummins KTA19 use the following link:

Overhaul Kit Catalog for Cummins KTA19 Engines

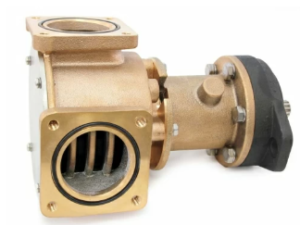

Are KTA19 overhaul kits different for marine and industrial engines?

Yes, overhaul kits for KTA19 engines can differ based on whether the engine is used in marine or industrial applications. While many internal components are the same, parts like cooling system components, exhaust manifolds, and fuel system settings may vary due to differences in operating environments. Always verify your engine’s application and CPL number to ensure the correct kit is selected.

Overhaul Kit Catalog for Cummins KTA19 Engines

Do overhaul kits include fuel system components?

Diesel Pro Power Overhaul Kits for Cummins KTA19 do not Included fuel system components, these must be purchase separately. When planning an overhaul, check the kit contents and consider adding fuel system parts if your injectors or pumps are due for service.

Fuel System & Related Components for Cummins KTA19

Injector & Related Components for Cummins KTA19 engine

How do I check for compatibility with my engine?

To confirm compatibility of an overhaul or rebuild kit with your Cummins KTA19, use the engine’s CPL number and serial number. These identifiers provide detailed information about your engine’s configuration, ensuring you receive the correct components. Suppliers like Diesel Pro Power can assist with cross-referencing these numbers to verify part compatibility.

What’s the warranty on aftermarket rebuild kits?

Most aftermarket rebuild kits come with an OEM matching warranty, typically covering 12 months from the date of purchase. This warranty often covers material defects and manufacturing issues but may exclude damage caused by improper installation or misuse. Always review the supplier’s warranty policy for specific terms and conditions.

Are there different types of rebuild kits?

Yes, there are different types of rebuild kits available for the KTA19, depending on the extent of the engine repair needed. Basic rebuild kits include components like pistons, liners, bearings, and gaskets, while comprehensive overhaul kits may add fuel system components, oil pumps, camshaft bushings, and more. Selecting the right kit depends on the condition of your engine and the scope of the rebuild.

Can I reuse old components during a rebuild?

Yes, some components can be reused during a rebuild if they meet OEM specifications and show no signs of excessive wear or damage. Parts like the crankshaft, connecting rods, camshaft, and rocker arms can often be reused after thorough inspection. However, critical components like gaskets, seals, and bearings should always be replaced to ensure long-term reliability.

What’s the difference between standard and oversized parts?

The difference between standard and oversized parts lies in their dimensions. Standard parts fit engines with original factory specifications, while oversized parts are designed for engines that have undergone machining, such as bored cylinders or ground crankshafts. Oversized components help restore proper clearances in engines with wear beyond standard limits.

Oversize 0.30″.

How do I measure cylinder liner wear?

To measure cylinder liner wear, use a dial bore gauge to check for out-of-roundness and taper. Take measurements at multiple points along the liner’s length and compare them to the specifications in the service manual. Excessive wear, scoring, or pitting indicates the need for liner replacement as part of the rebuild process.

Where to Find Reliable Aftermarket Parts for Cummins KTA19

Where can I buy aftermarket parts for the KTA19?

You can purchase aftermarket parts for the Cummins KTA19 from trusted suppliers like Diesel Pro Power, which offers a wide selection of high-quality components. Diesel Pro specializes in providing reliable parts for marine, industrial, and power generation applications, ensuring compatibility with your engine’s specific needs. Their user-friendly website, dieselpro.com, makes it easy to find and order the parts you need, with expert support available if you have questions.

Are aftermarket parts more affordable than OEM?

Yes, aftermarket parts are often 20-30% more affordable than OEM parts, making them a cost-effective choice for engine repairs and overhauls. Despite the lower price, reputable aftermarket suppliers like Diesel Pro Power ensure that these parts meet or exceed OEM standards in terms of quality and performance. This allows you to save money without compromising on the reliability of your Cummins KTA19.

How do I ensure I’m getting genuine aftermarket parts?

To ensure you’re purchasing genuine aftermarket parts, it’s important to buy from reputable suppliers like Diesel Pro Power, Inc. They offer verified products, backed by positive customer reviews and years of industry experience. Always look for clear product descriptions, part numbers, and the option to verify compatibility with your engine’s CPL (Control Parts List) number to avoid counterfeit or substandard components.

What’s the lead time for shipping KTA19 parts?

Orders for Cummins KTA19 parts from Diesel Pro Power are processed quickly, with most orders shipping out of their warehouse within 24 hours of placement, Monday through Friday. Lead times will vary depending on the shipping option you select during checkout, with expedited services available for urgent orders. International shipping is also available, with tracking information provided for all shipments.

Do suppliers offer technical support for part selection?

Yes, Diesel Pro Power provides expert technical support to assist you in selecting the correct parts for your Cummins KTA19. Their knowledgeable customer service team can help verify part compatibility using your engine serial number and CPL number, ensuring you get the right components the first time. This reduces the risk of ordering incorrect parts and helps keep your downtime to a minimum.

Can I return aftermarket parts if they don’t fit?

Yes, you can return parts if they don’t fit, but it’s best to verify compatibility before purchasing to avoid the hassle. Providing your engine serial number and CPL number to a Diesel Pro Power representative significantly reduces the chance of errors. If you’re unsure about a part, reach out to their sales team for guidance before finalizing your order to ensure a proper fit.

Is there a warranty on aftermarket KTA19 parts?

Yes, Diesel Pro Power offers a 1-year warranty on all parts for your Cummins KTA19. This warranty covers manufacturing defects and ensures peace of mind when purchasing aftermarket components. Always review the warranty terms and conditions for specific coverage details, and keep your proof of purchase handy in case you need to file a warranty claim.

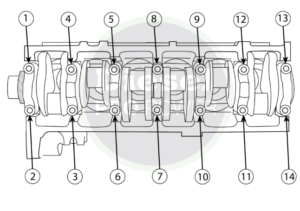

Can I find parts diagrams online?

Yes, many suppliers, including Diesel Pro Power, offer exploded view diagrams and detailed part schematics to assist with part identification. If you need a specific diagram for your Cummins KTA19, you can contact Colby at colbyu@dieselpro.com, and they will help you find the exact diagram you’re looking for. These diagrams are especially helpful when performing complex repairs or overhauls.

Do aftermarket suppliers offer bulk discounts?

At Diesel Pro Power, the price you see on DieselPro.com is always the best price up front, ensuring transparency and competitive pricing. While they do not offer traditional bulk discounts, their pricing structure is designed to provide value without the need for additional negotiations. This approach simplifies the buying process and guarantees that every customer receives the same fair price.

Are aftermarket turbochargers reliable for the KTA19?

Yes, high-quality aftermarket turbochargers for the Cummins KTA19 are designed to meet or exceed OEM standards. When sourced from reputable suppliers like Diesel Pro Power, these turbos offer excellent performance, durability, and efficiency. They undergo rigorous testing to ensure they can handle the demanding conditions typical of marine, industrial, and power generation applications.

How do I verify a part fits my engine model?

To verify that a part fits your Cummins KTA19, cross-reference the part with your engine’s CPL (Control Parts List) number and serial number. This information helps ensure compatibility, as even small differences between engine models can affect fitment. You can also consult Diesel Pro Power’s customer service team for expert assistance in confirming part compatibility.

What’s the difference between new and remanufactured parts?

New parts are manufactured from scratch, meeting current OEM specifications and standards. In contrast, remanufactured parts are previously used components that have been disassembled, cleaned, inspected, and rebuilt to OEM specifications. While remanufactured parts are often more cost-effective, both options are reliable when sourced from reputable suppliers like Diesel Pro Power.

Are aftermarket gaskets as good as OEM?

Yes, aftermarket gaskets can be just as good as OEM gaskets, provided they are sourced from reputable manufacturers like Diesel Pro Power. High-quality aftermarket gaskets are made from durable materials designed to withstand the extreme conditions within diesel engines, offering excellent sealing properties and long-term reliability.

Can I get custom parts for performance upgrades?

While some suppliers offer performance parts, Diesel Pro Power specializes in providing replacement parts that are designed to meet the original specifications of your Cummins KTA19. They do not offer recommendations for performance upgrades, focusing instead on helping you find the correct parts to maintain or restore your engine’s factory performance.

Is international shipping available for KTA19 parts?

Yes, Diesel Pro Power ships worldwide, serving customers in over 180 countries. They offer international shipping options with tracking, ensuring your Cummins KTA19 parts arrive safely and efficiently, no matter where you are located. Shipping costs and delivery times may vary based on destination and selected shipping method.

Do aftermarket suppliers provide tracking information?

Yes, tracking information is provided upon shipment of your Cummins KTA19 parts. Once your order ships, you’ll receive a tracking number via email, allowing you to monitor the status of your delivery. If you need additional assistance with tracking, you can contact Diesel Pro Power’s customer service team for support.

How do I identify counterfeit parts?

To avoid counterfeit parts, always buy from trusted sources like Diesel Pro Power, Inc., through their official website at www.dieselpro.com. Reputable suppliers ensure product authenticity, proper documentation, and warranties, reducing the risk of receiving substandard or fake components that could harm your engine.

Are there aftermarket kits for marine-specific KTA19 engines?

Yes, Diesel Pro Power offers tailored kits for marine-specific KTA19 engines, designed to meet the unique demands of marine environments. These kits include components optimized for corrosion resistance, cooling efficiency, and durability. To select the correct kit, refer to your engine’s CPL number on the Diesel Pro website.

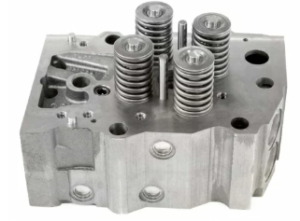

Can I find cylinder heads in aftermarket options?

Yes, Diesel Pro Power offers new cylinder heads for the Cummins KTA19. These aftermarket cylinder heads are built to meet OEM specifications, ensuring proper fitment, performance, and reliability. They are thoroughly tested for quality and durability, making them a cost-effective alternative to OEM replacements.

What payment options are accepted?

Diesel Pro Power accepts multiple payment options, including credit cards and wire transfers. This flexibility allows both domestic and international customers to complete transactions securely and conveniently. For large or international orders, wire transfers are a common choice, while credit card payments are quick and easy for standard purchases.

Links to Video Tutorials and Guides for Cummins KTA19

At Diesel Pro Power, we’re committed to not just supplying high-quality aftermarket parts but also providing the knowledge you need to install and maintain them correctly. Our Cummins KTA19 overhaul series on YouTube offers detailed, step-by-step video tutorials to guide you through every aspect of rebuilding and servicing your KTA19 engine. These videos cover essential topics, from cylinder kit assembly to engine startup, ensuring you have the support you need whether you’re a seasoned mechanic or tackling your first overhaul.

Where can I find KTA19 rebuild tutorials?

You can find comprehensive KTA19 rebuild tutorials on Diesel Pro Power’s YouTube channel. The overhaul process is divided into two detailed videos:

- KTA19 Overhaul (Part 1) focuses on the internal assembly process, covering tasks such as assembling cylinder kits, installing timing gears, the camshaft, front housing, and lubricating oil pump.

- KTA19 Overhaul (Part 2) covers the final assembly stages, including installing cylinder heads, rocker arms, fuel manifold, turbocharger, exhaust manifold, vibration damper, and engine startup procedures.

These tutorials are designed to walk you through every major step of the rebuild process with clear instructions and expert tips.

Are there injector installation guides available?

Yes, we offer a dedicated section in “KTA19 Overhaul (Part 2)” that focuses on injector installation. The segment titled “Assembling & Installing Injector Seals & Injectors” provides step-by-step instructions on properly assembling injector seals, installing the injectors, and ensuring correct alignment. Additionally, we cover injector timing adjustments to ensure optimal engine performance.

Can I watch tutorials on turbocharger replacement?

Yes, the “KTA19 Overhaul (Part 2)” video includes a section on turbocharger installation. In the segment titled “Installing The Turbo & Exhaust Manifold,” we demonstrate the correct procedures for mounting the turbo, securing the exhaust manifold, and ensuring proper gasket sealing. This section provides valuable tips on aligning the turbocharger correctly to prevent exhaust leaks and ensure efficient engine performance.

Are KTA19 cooling system service videos available?

While we don’t have a standalone video dedicated solely to the cooling system, cooling-related procedures are covered throughout the overhaul series. For example, in Part 1, we include the “Assembly of the Coolant Rail” section, which explains how to properly assemble and install coolant system components. Additionally, procedures like installing seals on the front housing indirectly cover key aspects of maintaining an effective cooling system.

Do videos cover torque specifications?

Yes, many of our KTA19 tutorials include detailed torque specifications and tightening sequences for critical engine components. For example, in “KTA19 Overhaul (Part 2)”, during the “Installing The Cylinder Heads” segment, we demonstrate the correct torque sequence for cylinder head bolts to ensure proper gasket sealing and prevent warping. Torque specs are clearly explained to help maintain engine reliability and prevent common assembly mistakes.

Torque Specs for Cummins KTA19

Are there troubleshooting videos for common engine issues?

While our current focus is on overhaul and assembly procedures, many of the concepts covered in the KTA19 Overhaul videos can assist with troubleshooting common engine issues. By learning how to correctly install components like the fuel manifold, injectors, and cam followers, you’ll gain insights into identifying potential causes of problems such as poor fuel delivery, misfires, or excessive oil consumption. We plan to expand our troubleshooting content in future videos.

Can I find videos on fuel system calibration?

Yes, we cover essential fuel system calibration procedures in our videos. In “KTA19 Overhaul (Part 2),” the segment titled “Setting Injector Timing Height Using The OBC Method” provides a detailed guide on how to calibrate the fuel injectors for proper timing and performance. This process is critical for ensuring efficient fuel delivery, reducing emissions, and optimizing engine power output.

Are there marine-specific KTA19 videos?

Currently, our KTA19 video series is designed to cover general overhaul and maintenance procedures that apply to both marine and industrial engines. While we don’t have marine-specific videos focusing solely on marine propulsion systems or cooling configurations, the assembly, installation, and calibration techniques covered in our tutorials are applicable to marine engines as well. We plan to release marine-specific content in the future to address the unique challenges of marine environments.

Do tutorials cover engine disassembly?

Yes, the “KTA19 Overhaul (Part 1)” video covers key steps in the engine disassembly process, especially regarding the removal and replacement of critical components. While it primarily focuses on assembly, tasks like installing the camshaft, timing gears, and cam followers involve procedures that require partial disassembly. Future videos will expand on full disassembly techniques for in-depth engine servicing.

Are cylinder head installation videos available?

Absolutely! In “KTA19 Overhaul (Part 2),” the section titled “Installing The Cylinder Heads” provides a detailed guide on how to install cylinder heads correctly, including gasket preparation, head alignment, and the proper torque sequence for securing the cylinder head bolts. We emphasize critical steps to prevent head gasket failures, such as checking liner protrusion, surface flatness, and proper torque settings.

Additional KTA19 Video Resources

Here’s a breakdown of the key topics covered in our Cummins KTA19 overhaul series:

KTA19 Overhaul (Part 1):

- 0:16 – Assembly of the Cylinder Kits

- 25:10 – Installation of the Seals on the Front Housing

- 32:20 – Assembly of the Coolant Rail

- 34:54 – Installing Front End Plate

- 39:27 – Installing Lubricating Oil Pump

- 40:24 – Installing Timing Gears

- 43:45 – Installing Camshaft

- 45:50 – Installing Front Housing

- 48:19 – Installing Cam Followers

- 50:54 – Installing Cylinder Kits & Connecting Rods

- 52:17 – Measuring the Liner Height

KTA19 Overhaul (Part 2):

- 0:16 – Tour of Godwin Singer Machine Shop

- 1:16 – Installing the Cylinder Heads

- 9:35 – Installing Rocker Cover Housing

- 14:43 – Installing the Push Rods

- 15:54 – Installing the Fuel Manifold

- 20:15 – Installing the Oil Pan

- 22:33 – Installing the Cam Follower Cover & Hand Hole Cover

- 23:14 – Installing the Murphy Switch for Oil Level

- 23:54 – Installing the Turbo & Exhaust Manifold

- 27:59 – Installing Front Seal

- 29:52 – Installing Vibration Damper

- 31:24 – Assembling & Installing Injector Seals & Injectors

- 39:26 – Installing Rocker Arms

- 43:19 – Setting Injector Timing Height Using the OBC Method

- 48:45 – Installing the Valve Covers

- 50:22 – Engine Startup!

Where to Watch

You can find all of these tutorials on Diesel Pro Power’s official YouTube channel. Just search for “Diesel Pro Power Cummins KTA19” or visit www.youtube.com/c/DieselProPower to start watching. Don’t forget to subscribe to our channel to stay updated on the latest tutorials and Cummins KTA19 service guides.

Additional FAQs About Maintenance and Troubleshooting for Cummins KTA19

How often should I change the oil?

It is recommended to change the oil every 250 hours of operation or as specified in the Cummins KTA19 service manual, depending on the operating environment. Engines operating under harsh conditions, such as heavy loads, dusty environments, or extreme temperatures, may require more frequent oil changes. Regular oil changes are essential to maintain proper lubrication, reduce wear, and prevent contaminants from causing engine damage.

What type of oil should I use?

For optimal performance, the Cummins KTA19 requires SAE 15W-40 diesel engine oil with an API CI-4 or higher rating. This oil type offers excellent protection against wear, oxidation, and soot buildup, especially under heavy-duty conditions. If the engine operates in extremely cold environments, consider using a lower viscosity oil like SAE 10W-30, but always refer to the service manual for temperature-specific recommendations.

What causes excessive oil consumption?

Excessive oil consumption in the Cummins KTA19 can be caused by worn piston rings, damaged valve seals, or leaking turbocharger seals. These issues allow oil to enter the combustion chamber or exhaust system, leading to increased oil usage and visible signs such as blue smoke from the exhaust. Additionally, overfilled crankcases, clogged breather systems, or poor-quality oil can contribute to higher consumption rates.

How do I troubleshoot overheating issues?

To troubleshoot overheating issues in the Cummins KTA19, start by checking the coolant levels and ensuring the coolant mixture is correct. Inspect the thermostat to verify it is opening and closing properly, as a stuck thermostat can restrict coolant flow. Additionally, examine the water pump for signs of wear, leaks, or poor circulation, and check for blocked radiators, clogged coolant passages, or faulty fan operations, all of which can impair cooling efficiency.

Why is my KTA19 losing power?

A loss of power in the KTA19 can result from several issues, including clogged fuel filters, which restrict fuel flow to the injectors. Injector problems, such as poor spray patterns or incorrect timing, can also cause reduced combustion efficiency. Additionally, turbocharger failures, including damaged blades or leaks in the intake system, can limit air supply, reducing overall engine power. Always perform a thorough inspection of the fuel, air, and exhaust systems to identify the root cause.

What is the normal operating temperature?

The normal operating temperature for the Cummins KTA19 is typically between 180°F and 200°F (82°C to 93°C). Temperatures consistently above this range may indicate issues like coolant flow restriction, thermostat malfunction, or radiator problems. Conversely, if the engine runs too cool, it could lead to poor fuel efficiency and increased wear, often caused by a stuck-open thermostat or faulty temperature sensors.

How often should I replace fuel filters?

Fuel filters on the Cummins KTA19 should be replaced every 500 hours of operation or sooner if poor fuel quality is a concern. If the engine operates in environments with contaminated fuel or high particulate levels, more frequent changes may be necessary. Replacing fuel filters regularly helps maintain optimal fuel flow, prevents injector clogging, and reduces the risk of engine performance issues.

How do I adjust valve lash on the KTA19?

To adjust the valve lash on the KTA19, you’ll need to follow the specific procedures outlined in the service manual. This process typically involves bringing the engine to Top Dead Center (TDC) for the appropriate cylinder, loosening the lock nut on the adjusting screw, and using a feeler gauge to set the correct clearance between the rocker arm and the valve stem. Proper valve lash adjustment ensures optimal engine performance, fuel efficiency, and reduces valve train wear.

What are signs of a failing turbocharger?

Signs of a failing turbocharger in the Cummins KTA19 include excessive smoke (especially blue or black), a noticeable loss of power, and unusual noises such as whining, grinding, or rattling sounds. You may also notice oil leaks around the turbo housing, poor acceleration, or increased exhaust temperatures. A failing turbo can lead to further engine damage if not addressed promptly, so it’s essential to inspect for shaft play, damaged blades, and restricted airflow.

Can I use biodiesel in the KTA19?

Yes, the Cummins KTA19 can operate on biodiesel blends up to B20 (20% biodiesel, 80% petroleum diesel), provided the fuel meets ASTM D6751 standards for biodiesel quality. Biodiesel must be properly stored and handled to prevent contamination, as it is more prone to water absorption and microbial growth than conventional diesel. Regular fuel filter changes are recommended when transitioning to biodiesel, as it can loosen deposits in the fuel system.

Installation and Setup FAQs for Cummins KTA19

What is the proper torque sequence for the KTA19 cylinder head bolts?

Torque Specs for Cummins KTA19

The proper torque sequence for the KTA19 cylinder head bolts follows a spiral or cross pattern, starting from the center bolts and moving outward in a circular fashion. This sequence ensures even distribution of clamping force, preventing cylinder head warping or gasket failure. While the general sequence remains the same, the exact torque values and steps vary depending on the engine’s CPL (Control Parts List) number, so it’s crucial to refer to the service manual for specific torque specifications, stages, and tightening angles.

How do I find the CPL (Control Parts List) number on my KTA19?

The CPL number is an essential identifier for ordering parts and verifying engine configurations. You can find it on the engine’s dataplate, which is typically located on the valve cover or the side of the engine block. This metal plate includes key information such as the engine serial number, model, horsepower rating, and CPL number. Having the CPL number readily available helps ensure that you receive correct parts and accurate service recommendations when maintaining or overhauling your KTA19.

Do I need to replace head bolts during every rebuild?

You don’t always need to replace cylinder head bolts during every rebuild, but it’s highly recommended to inspect them carefully for signs of stretching, corrosion, or thread damage. Head bolts can stretch beyond their elastic limit after multiple torque cycles, leading to improper clamping force. To check for stretching, compare the bolt length to factory specifications or look for signs of necking. Replace any bolts that are out of spec to prevent head gasket failure or uneven sealing.

What are the valve lash specifications for the KTA19?

The valve lash specifications for the Cummins KTA19 are generally set at:

- Intake: 0.014 inches (0.36 mm)

- Exhaust: 0.027 inches (0.69 mm)

However, these values can vary depending on the engine’s CPL number, so always consult the Cummins service manual for your specific model. Proper valve lash adjustment is critical for optimal engine performance, ensuring efficient airflow, accurate fuel delivery, and preventing valve damage due to excessive clearance or tightness.

How do I properly align the timing marks on the KTA19?

To properly align the timing marks on the KTA19, you need to match the timing marks on the crankshaft, camshaft, and idler gears. These marks are typically engraved dots or lines that must align perfectly to ensure correct valve timing and fuel injection synchronization. Start by rotating the crankshaft to Top Dead Center (TDC) for cylinder #1, then verify that all gear marks are aligned as specified in the service manual. Incorrect alignment can lead to poor performance, hard starting, or severe engine damage.

Can I install the pistons without a ring compressor?

No, you cannot install pistons without a ring compressor. A piston ring compressor is essential for compressing the piston rings tightly against the piston, allowing the assembly to slide smoothly into the cylinder liner without damaging the rings or cylinder walls. Attempting installation without this tool can lead to broken rings, scored liners, and poor compression after assembly. Always ensure the ring gaps are correctly positioned before compressing them for installation.

What’s the recommended break-in procedure after a KTA19 rebuild?

The recommended break-in procedure for a Cummins KTA19 after a rebuild is to operate the engine under light to moderate load for the first 50 hours. During this period:

- Avoid prolonged idling, as it can cause incomplete ring seating.

- Gradually increase the load while avoiding maximum throttle or heavy loads for extended periods.

- Monitor oil pressure, temperature, and coolant levels regularly.

This controlled break-in process allows new components like piston rings, cylinder liners, and bearings to seat properly, ensuring optimal performance and long-term reliability.

Should I pre-lubricate the engine after a rebuild?

Yes, it is essential to pre-lubricate the engine after a rebuild to ensure that oil reaches all critical components before the first startup. This process helps prevent dry starts, which can cause severe wear or damage to bearings, cam lobes, and cylinder walls. You can achieve this by either:

- Priming the oil system manually using an external pump to circulate oil throughout the engine.

- Pre-filling oil galleries, filters, and lubricating components like the camshaft, rocker arms, and piston rings during assembly.

Proper pre-lubrication significantly reduces initial friction and promotes a smooth first start.

What’s the proper procedure for bleeding the fuel system?

To bleed the fuel system on a Cummins KTA19, follow these steps:

- Loosen the fuel injector lines slightly at the injector connections.

- Crank the engine using the starter motor until you see fuel flowing steadily without air bubbles from the injector lines.

- Tighten the injector line fittings once air has been purged.

- Start the engine and allow it to idle while checking for smooth operation.

Bleeding the fuel system is crucial after any fuel filter replacement, line disconnection, or rebuild to prevent hard starting and rough idling caused by trapped air.

Do I need to replace the harmonic balancer during every overhaul?

You don’t necessarily need to replace the harmonic balancer (or vibration damper) during every overhaul, but it should be thoroughly inspected for signs of wear, cracks, or rubber deterioration. The harmonic balancer helps reduce torsional vibrations in the crankshaft, which, if left unchecked, can cause premature crankshaft failure.

- Look for cracks in the rubber isolator, misalignment, or visible damage.

- If any defects are found, or if the balancer has over 8,000 to 10,000 hours of operation, it’s recommended to replace it as part of preventive maintenance.

Neglecting a faulty harmonic balancer can lead to engine vibration issues and internal damage over time.

Cooling System FAQs for Cummins KTA19

What is the coolant capacity of the Cummins KTA19?

The coolant capacity of the Cummins KTA19 ranges from 51 to 60 liters (13.5 to 15.8 gallons), depending on the specific application and the type of cooling system configuration (marine, industrial, or generator set). This capacity includes the engine block, radiator, hoses, and coolant reservoir. Always check your engine’s service manual for precise capacity figures, as custom installations or additional cooling components may affect the total volume.

How often should I flush the cooling system?

You should flush the cooling system every 1,000 hours of operation or annually, whichever comes first. Regular flushing helps remove scale, rust, debris, and old coolant additives that can reduce cooling efficiency and cause corrosion. Engines operating in harsh environments (like high dust, marine saltwater exposure, or extreme heat) may require more frequent flushing. Always refill with fresh coolant and the correct additives after flushing to maintain optimal cooling performance.

What type of coolant should I use?

For the Cummins KTA19, it’s recommended to use a heavy-duty coolant (antifreeze) formulated for diesel engines, such as an ethylene glycol-based coolant with proper additives to prevent cavitation, corrosion, and scale buildup. Look for coolants that meet Cummins CES14603 or equivalent specifications. Using a coolant with supplemental coolant additives (SCAs) helps protect against liner pitting (cavitation erosion), a common issue in heavy-duty diesel engines. Avoid mixing different coolant types unless specified as compatible by the manufacturer.

How do I know if my water pump needs replacing?

Common signs that your water pump needs replacing include:

- Coolant leaks from the weep hole or around the pump gasket, indicating seal failure.

- Overheating issues, especially if the coolant level is adequate but the engine still runs hot.

- Unusual noises, such as grinding, whining, or squealing, which may indicate worn bearings or a failing impeller.

- Coolant circulation issues, which can be diagnosed by checking if the radiator hoses remain cool even when the engine is hot.

If any of these symptoms are present, inspect the pump closely and replace it if needed to avoid engine overheating and potential damage.

What causes cavitation in the KTA19 cooling system?

Cavitation in the KTA19 cooling system is primarily caused by the formation and collapse of vapor bubbles near metal surfaces, which can lead to pitting and erosion, especially around the cylinder liners. Common causes include:

- Inadequate coolant additives (lack of proper SCAs to prevent bubble formation).

- Low coolant levels, which reduce system pressure and promote vapor bubble formation.

- Improper system pressure, either from a faulty radiator cap or pressure imbalances.

- High engine loads or rapid throttle changes, increasing coolant flow turbulence.

Prevent cavitation by using diesel-rated coolant with SCAs, maintaining proper coolant levels, and ensuring the cooling system operates under the correct pressure.

Can I run the engine without a thermostat?

No, you should never run the Cummins KTA19 without a thermostat. The thermostat regulates the engine’s operating temperature by controlling the flow of coolant between the engine and radiator. Without it:

- The engine may run too cold, leading to poor fuel combustion, reduced efficiency, and increased emissions.

- In some cases, the lack of temperature regulation can cause localized overheating, damaging critical components.

- It can also cause premature wear on engine parts due to inconsistent thermal expansion.

Always replace a faulty thermostat with the correct OEM-spec part to ensure the engine maintains its optimal operating temperature.

How do I pressure test the cooling system?

To pressure test the KTA19 cooling system, follow these steps:

- Ensure the engine is cool before starting.

- Remove the radiator cap and attach a cooling system pressure tester to the radiator or coolant reservoir.

- Pump the tester to the pressure rating specified on the radiator cap, usually around 15 psi (1 bar) for the KTA19.

- Observe the pressure gauge:

- If the pressure drops quickly, there may be a leak.

- If it holds steady, the system is likely sealed properly.

- Inspect for visible leaks around hoses, gaskets, radiator seams, water pump seals, and the cylinder head.

This test helps identify internal leaks, such as head gasket failures or cracked components, even if external leaks aren’t visible.

What’s the proper way to bleed air from the cooling system?

To bleed air from the KTA19 cooling system, follow these steps:

- Slowly fill the radiator or coolant reservoir with coolant to minimize air pockets.

- Start the engine and let it idle with the radiator cap off to allow trapped air to escape.

- As the engine warms up, the thermostat will open, allowing coolant to circulate and pushing air bubbles to the top.

- If equipped, open any bleed valves on the cooling system to release air.

- Keep adding coolant as the level drops until it stabilizes.

- Once all bubbles are gone, replace the radiator cap and bring the engine to operating temperature.

Bleeding the system properly prevents air pockets, which can cause overheating, hot spots, and coolant flow restrictions.

What causes fluctuating coolant temperature?

Fluctuating coolant temperature in the KTA19 can be caused by several issues, including:

- A stuck thermostat, which opens and closes erratically, leading to inconsistent coolant flow.

- Air trapped in the cooling system, creating hot spots and restricting coolant circulation.

- A failing water pump, causing intermittent coolant flow or reduced circulation.

- Low coolant levels, which reduce the system’s ability to regulate temperature.

- A malfunctioning temperature sensor or gauge, giving false readings.

Consistent temperature fluctuations can lead to thermal stress on engine components, so it’s important to diagnose and fix the underlying cause promptly.

Is it normal for the coolant level to drop slightly after engine operation?

Yes, it’s normal for the coolant level to drop slightly after engine operation due to thermal expansion. As the coolant heats up, it expands, and some may overflow into the expansion tank. When the engine cools, the coolant contracts, causing the level to appear lower.

However, excessive coolant loss or frequent topping off could indicate:

- A coolant leak (external from hoses, radiator, water pump, etc.).

- An internal leak (such as a blown head gasket, which may cause coolant to enter the combustion chamber).

- A cracked cylinder liner or block allowing coolant to leak internally.

If you notice persistent coolant loss, inspect the system for leaks or perform a pressure test to identify hidden issues.

Fuel System FAQs for Cummins KTA19

How often should I change the fuel filters?

For optimal performance, fuel filters on the Cummins KTA19 should be changed every 500 hours of operation or more frequently if the engine operates in dusty environments or areas with poor fuel quality. Contaminants like dirt, water, and debris can clog fuel filters, leading to reduced fuel flow, hard starting, and poor engine performance. Regular filter changes help maintain proper fuel pressure, improve fuel efficiency, and prevent injector damage. Always refer to the service manual for any specific recommendations based on your engine’s application.

What causes hard starting in the KTA19?

Hard starting in the Cummins KTA19 can be caused by several factors, with the most common being:

- Air in the fuel system, which disrupts fuel flow and causes improper combustion.

- A weak or failing fuel pump that can’t maintain adequate fuel pressure.

- Clogged injectors that restrict fuel delivery, leading to poor atomization and inefficient combustion.

Other causes may include low compression, faulty glow plugs (if equipped for cold climates), or fuel contamination. Proper diagnosis involves checking for fuel leaks, verifying fuel pressure, and ensuring the fuel system is properly primed.

Can I adjust the fuel injection timing?

Yes, the fuel injection timing on the KTA19 can be adjusted, but it requires specialized tools and strict adherence to procedures outlined in the Cummins service manual. Adjusting the timing involves setting the correct injector height and ensuring the camshaft and crankshaft are properly synchronized. Incorrect fuel timing can lead to poor engine performance, excessive smoke, reduced fuel efficiency, and even engine damage. It’s recommended to have a qualified technician perform this adjustment unless you have experience with diesel fuel systems.

How do I know if my injectors need replacement?

Signs that your injectors may need replacement include:

- Rough idling or unstable RPMs, especially at low speeds.

- Increased fuel consumption, indicating poor combustion efficiency.

- Black smoke from the exhaust, caused by unburned fuel due to poor injector spray patterns.

- Hard starting or prolonged cranking times.

- Knocking noises or misfires under load.

If you experience these symptoms, consider performing an injector balance test or leak-down test to diagnose the issue. Replacing faulty injectors promptly helps maintain optimal performance and prevents damage to the pistons or cylinder walls.

What’s the proper fuel pressure for the KTA19?

The recommended fuel pressure for the Cummins KTA19 is typically between 30-45 psi (2-3 bar) at idle, with variations depending on the engine’s specific configuration and application. Fuel pressure should increase under load to ensure adequate fuel delivery. Low fuel pressure can result in poor performance, hard starting, and injector damage, while excessively high pressure can strain the fuel system components. Always refer to the service manual for the precise fuel pressure specifications for your engine model.

How do I test the fuel pump for proper operation?

To test the fuel pump on a Cummins KTA19, follow these steps:

- Install a fuel pressure gauge on the fuel supply line, preferably after the fuel filter for accurate readings.

- Start the engine and monitor the fuel pressure at idle. It should be between 30-45 psi (2-3 bar).

- Rev the engine to check if the fuel pressure increases under load, indicating proper pump operation.

- Inspect for leaks around the fuel lines, fittings, and pump seals.

- If pressure is low, check for clogged filters, air in the system, or a weak pump.

Consistent fuel pressure and flow are crucial for maintaining optimal engine performance.

Can contaminated fuel damage my KTA19?

Yes, contaminated fuel can severely damage the Cummins KTA19’s fuel system. Contaminants such as dirt, water, algae, or metal particles can:

- Clog fuel filters and injectors, reducing fuel flow and causing poor combustion.

- Damage the fuel pump, leading to premature wear of internal components.

- Cause corrosion within the fuel lines, injectors, and pump.

- Increase the risk of injector failure due to abrasive particles.

To prevent damage, always use clean, high-quality diesel fuel, regularly replace fuel filters, and consider using a fuel water separator to remove moisture before it reaches the engine.

What’s the recommended fuel for the KTA19?

The Cummins KTA19 is designed to run on diesel fuel that meets ASTM D975 standards, which ensures the fuel has the appropriate cetane rating, lubricity, and sulfur content. Depending on regional regulations, the engine can operate on:

- Ultra-low sulfur diesel (ULSD) with a sulfur content of 15 ppm, suitable for modern emissions requirements.

- Standard diesel fuel with higher sulfur content, commonly used in off-road or marine applications.

Always refer to the service manual for fuel recommendations based on your specific application, and avoid using blended fuels or biodiesel without confirming compatibility.

How do I drain water from the fuel system?

To drain water from the fuel system on the Cummins KTA19:

- Locate the fuel-water separator drain valve, typically near the primary fuel filter.

- Place a container underneath to catch the drained fluid.

- Open the drain valve slowly and allow the water and contaminated fuel to flow out until you see clean, clear diesel fuel.

- Close the drain valve securely.

- If a large amount of water was drained, consider replacing the fuel filters and checking the fuel tank for water contamination.

Regularly draining water helps prevent corrosion, injector damage, and poor engine performance.

What causes white smoke from the exhaust?

White smoke from the exhaust of the KTA19 typically indicates unburned fuel or coolant leakage into the combustion chamber. Common causes include:

- Injector issues, such as faulty nozzles or poor spray patterns causing incomplete combustion.

- Low compression, often due to worn piston rings, cylinder wear, or valve sealing issues.

- Coolant leakage from a blown head gasket, cracked cylinder head, or liner seal failure, causing steam to exit the exhaust.

- Cold weather starting, where the fuel doesn’t vaporize properly in low temperatures.

If the white smoke persists after warm-up, it’s important to diagnose the issue promptly to prevent further engine damage.

What type of oil does the KTA19 require?

The Cummins KTA19 requires SAE 15W-40 diesel engine oil with an API CI-4 rating or higher, which provides excellent protection against wear, oxidation, and soot buildup under heavy-duty conditions. This oil type ensures optimal lubrication, thermal stability, and detergent properties to keep the engine clean and running smoothly. In extreme temperature environments, refer to the Cummins service manual for specific recommendations—SAE 10W-30 may be suitable for cold climates, while higher viscosity oils like SAE 20W-50 might be used in extremely hot conditions.

How do I know if my oil cooler is failing?

Signs of a failing oil cooler in the KTA19 include:

- Oil contamination with coolant, resulting in a milky or frothy oil appearance, indicating an internal leak where coolant mixes with engine oil.

- Engine overheating, as the oil cooler also plays a role in maintaining the engine’s operating temperature.

- Low oil pressure, caused by coolant thinning the oil or a restricted oil flow due to a clogged cooler.

- External oil or coolant leaks around the cooler housing or fittings.

A failing oil cooler can lead to engine overheating, poor lubrication, and potential engine failure, so it’s critical to inspect and replace it if these symptoms are present.

How often should I change the oil and filter?

The oil and filter on the Cummins KTA19 should be changed every 250 hours of operation under normal conditions. In severe environments, such as extreme heat, dusty conditions, heavy load operations, or extended idling, more frequent oil changes may be necessary—sometimes as often as every 150 hours. Regular oil changes help maintain optimal lubrication, prevent sludge buildup, and reduce engine wear, significantly extending the engine’s service life. Always use high-quality filters designed for the KTA19 to ensure proper filtration.

What causes low oil pressure in the KTA19?

Low oil pressure in the Cummins KTA19 can result from several issues, including:

- Worn engine bearings (main or rod bearings), leading to increased clearance and reduced oil pressure.

- Clogged oil filters, which restrict oil flow and reduce pressure to critical engine components.

- A faulty oil pump, which may have worn gears, a weak pressure relief valve, or internal leakage.

- Low oil levels, often due to leaks or high oil consumption.

- Oil viscosity issues, such as using oil that is too thin for the operating temperature.

- Crankcase pressure problems, where excess blow-by gases affect oil circulation.

Low oil pressure should be addressed immediately, as it can cause insufficient lubrication, leading to catastrophic engine damage.

Can I use synthetic oil in the KTA19?

Yes, you can use synthetic oil in the Cummins KTA19 as long as it meets the manufacturer’s specifications, particularly the required API CI-4 or higher rating. Synthetic oils offer several advantages, including improved thermal stability, better resistance to oxidation, and enhanced flow in cold temperatures. This makes synthetic oil especially beneficial in extreme temperature environments or for engines that experience frequent start-stop cycles. However, always check the service manual to ensure compatibility with your specific engine configuration.

What’s the oil capacity of the KTA19?

The oil capacity of the Cummins KTA19 is approximately 51 liters (13.5 gallons), but this can vary slightly depending on the specific engine configuration and optional equipment (such as additional oil coolers or filtration systems). When performing an oil change, ensure that the engine is fully drained, including the oil filter and any external coolers, to accurately refill to the correct capacity. Always check the dipstick after refilling to confirm proper oil levels.

What causes oil leaks around the valve cover?

Oil leaks around the valve cover of the KTA19 are typically caused by:

- Worn or damaged valve cover gaskets, which lose their sealing ability over time due to heat and pressure.

- Improperly torqued valve cover bolts, either too loose (causing leaks) or too tight (damaging the gasket).

- Crankcase pressure issues, where excessive pressure forces oil past seals and gaskets. This can result from a clogged crankcase ventilation system or blow-by gases from worn piston rings.

- Cracked valve covers, often due to over-tightening or physical damage.

Addressing oil leaks promptly helps prevent oil contamination, fire hazards, and engine damage caused by low oil levels.

How do I check for oil dilution in the KTA19?

To check for oil dilution (contamination of engine oil with fuel, coolant, or water) in the KTA19:

- Perform regular oil analysis through a lab, which can detect even small amounts of fuel, coolant, or water contamination.

- Visually inspect the oil for signs of contamination:

- Milky or frothy oil indicates coolant contamination.

- Thin, fuel-smelling oil suggests fuel dilution.

- Water droplets in the oil, especially on the dipstick, indicate water contamination.

- Monitor oil levels frequently—if the oil level rises unexpectedly, it may be due to fuel dilution.

- Check for excessive blow-by gases, which can contribute to contamination issues.

If oil dilution is detected, it’s crucial to identify and fix the root cause, as contaminated oil can lead to bearing damage, reduced lubrication, and premature engine wear.

What’s the normal oil pressure range for the KTA19?

The normal oil pressure range for the Cummins KTA19 is typically:

- 30-60 psi (2-4 bar) at normal operating temperature (hot).

- Higher oil pressure when cold, often exceeding 60 psi (4 bar) until the oil warms up and thins.

Oil pressure may fluctuate slightly depending on engine load, speed, and temperature. Consistently low oil pressure may indicate issues like worn bearings, a failing oil pump, or low oil levels. Conversely, abnormally high oil pressure could be due to a blocked oil passage or a malfunctioning pressure relief valve. Regular monitoring of oil pressure is essential to prevent engine damage from inadequate lubrication.

How do I prevent sludge buildup in the engine?

To prevent sludge buildup in the Cummins KTA19:

- Change the oil and filters regularly, following the recommended intervals (every 250 hours or more frequently in severe conditions).

- Use high-quality diesel engine oil with proper detergent and dispersant additives that help break down contaminants.

- Maintain proper crankcase ventilation to prevent moisture and combustion byproducts from accumulating in the oil.

- Avoid prolonged idling, which causes incomplete combustion and increases soot buildup.

- Ensure the engine reaches its optimal operating temperature during operation, as short trips or low-load conditions can promote sludge formation.

- Perform periodic oil analysis to detect early signs of contamination or degradation.

Proper maintenance practices help reduce sludge formation, ensuring clean oil circulation and extending engine life.

Disclaimer

For technical details not covered in this guide, consult the official Cummins KTA19 service manual or reach out to certified Cummins service professionals. Always follow manufacturer recommendations for service procedures and part compatibility to ensure engine reliability and safety.

Parts Catalog for Cummins KTA19 Marine Engine

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588