Determining whether your Detroit Diesel Inline 71 Series engine is equipped with a right-hand or left-hand blower is essential for proper maintenance and part replacement. This guide will assist you in identifying the blower orientation specific to models such as the 3-71, 4-71, and 6-71.

Understanding Engine Orientation

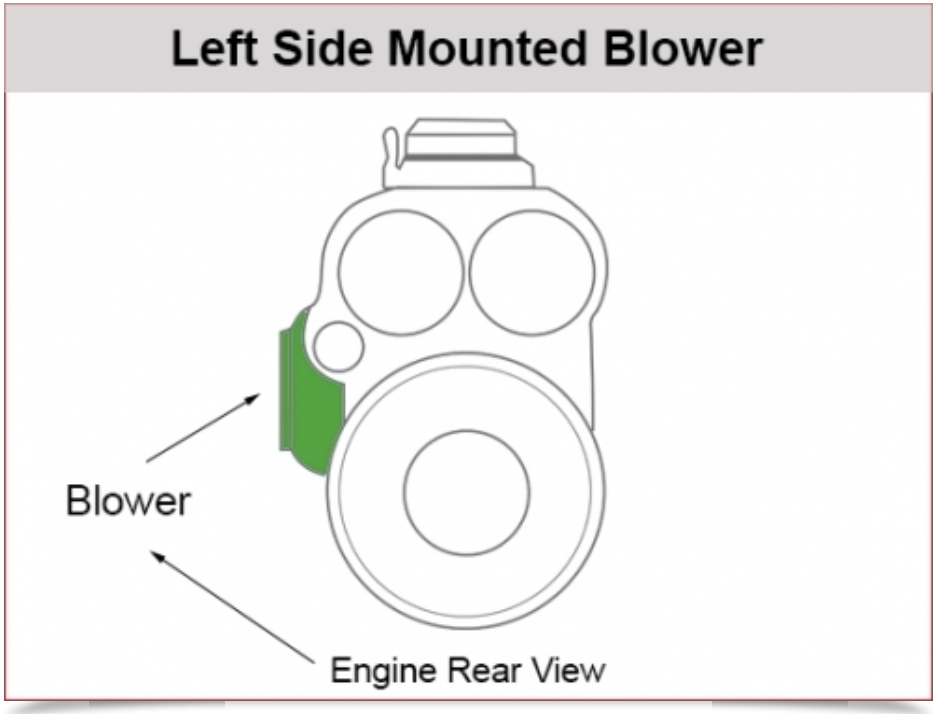

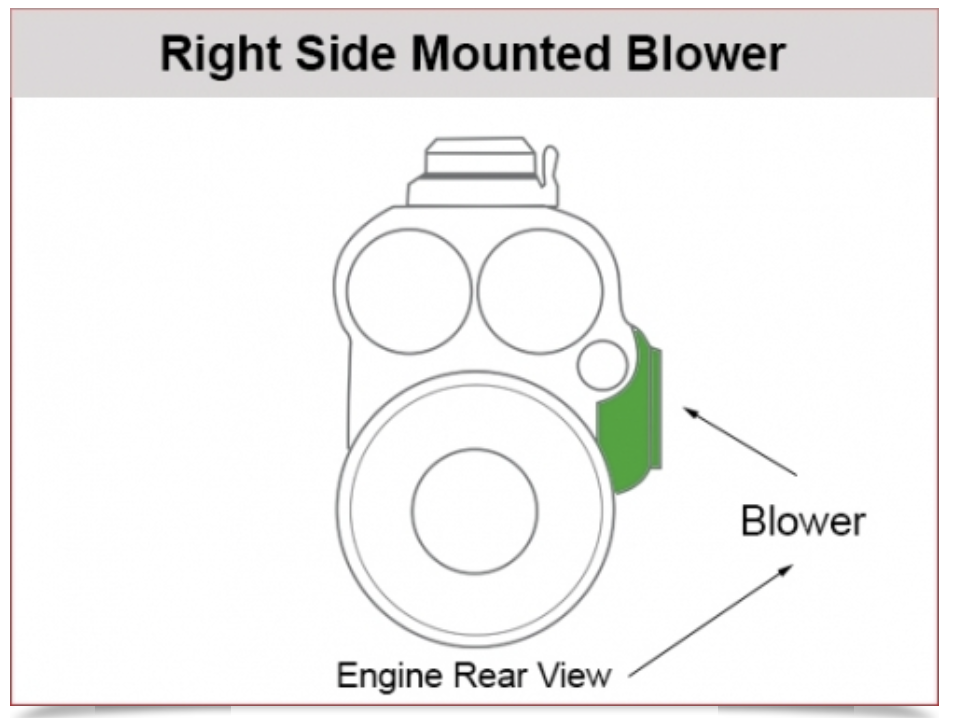

To accurately identify the blower’s orientation, position yourself at the rear of the engine, facing the flywheel. This perspective is standard for determining component locations and rotations in engine terminology.

Identifying Blower Position

Left-Hand Blower:

If the blower is mounted on the left side of the engine (from your viewpoint at the flywheel end), it is classified as a left-hand blower.

- Right-Hand Blower:

Conversely, if the blower is situated on the right side, it is a right-hand blower.

Why Detroit Diesel Made Both Right-Hand and Left-Hand Blowers for Inline 71 Series Engines

The Detroit Diesel 71 Series engines, such as the 3-71, 4-71, and 6-71 models, are iconic in the diesel engine world. Designed for versatility and durability, these engines were used across various industries, including marine, industrial, military, and transportation applications. One of the most distinct features of these engines is the availability of both right-hand and left-hand blowers. But why did Detroit Diesel design this dual-orientation system?

The answer lies in application versatility, engine configurations, and efficient engine design. Below, we break down the primary reasons.

1. Adapting to Different Engine Configurations

Detroit Diesel designed their engines to accommodate a wide variety of configurations, whether as standalone power units, twin-engine systems, or auxiliary setups. To achieve this, the orientation of key components—like the blower—had to be versatile enough to adapt to different installations.

Standalone Configurations

For engines installed as standalone systems, right-hand blowers were the standard choice. These engines followed conventional designs where the blower is mounted on the right-hand side (when viewed from the flywheel). This setup was straightforward and ideal for single-engine installations across industrial equipment, trucks, and agricultural machinery.

Twin-Engine Systems

Twin-engine systems, common in marine applications, required a mirrored configuration to ensure balance. One engine would rotate clockwise (right-hand rotation), while the other would rotate counterclockwise (left-hand rotation). This setup ensured that the propellers spun in opposite directions, balancing thrust and eliminating torque steer.

- Right-Hand Engine + Left-Hand Blower: Used in standard rotation engines.

- Left-Hand Engine + Right-Hand Blower: Essential for counter-rotating engines.

Without the option of dual blower orientations, achieving this balance would have required extensive and costly modifications.

Auxiliary Power Units

Detroit Diesel engines were often used as auxiliary power units for tasks such as powering pumps, winches, or generators. Space constraints in these applications could dictate the orientation of components. By offering both right-hand and left-hand blowers, Detroit Diesel ensured that their engines could adapt to tight installation spaces without sacrificing performance.

Maximizing Versatility

The availability of both blower orientations eliminated the need for costly customization. It also enhanced Detroit Diesel’s reputation as a go-to engine manufacturer for applications where flexibility and adaptability were critical.

2. Dual Rotation Capability

One of the most innovative aspects of the Inline 71 Series was its ability to support both right-hand (clockwise) and left-hand (counterclockwise) crankshaft rotations. This feature made the engines suitable for diverse applications, especially in marine and industrial setups where specific rotational requirements were essential.

Airflow Alignment

The blower is a critical component of the engine, responsible for delivering air to the intake system. Its internal gearing and design must synchronize with the engine’s rotation to ensure proper airflow. A mismatch between the engine’s rotation and the blower’s orientation would result in:

- Disrupted airflow.

- Reduced engine performance.

- Potential engine damage.

By manufacturing both right-hand and left-hand blowers, Detroit Diesel ensured that airflow remained consistent regardless of the engine’s rotational direction. This design feature was especially important for maintaining efficiency in twin-engine setups and non-standard installations.

Enhanced Durability

The ability to match blower orientation with engine rotation contributed to the engine’s durability. Proper airflow minimized wear and tear on components, ensuring the engine could perform optimally even in challenging conditions.

3. Marine Applications

The marine industry was one of the largest markets for Detroit Diesel engines, and the availability of both right-hand and left-hand blowers played a crucial role in the company’s success in this sector. Marine vessels often use twin-engine setups to power dual propellers, and these setups require precise coordination.

Balancing Propulsion

In a twin-engine marine vessel, one engine typically rotates clockwise while the other rotates counterclockwise. This ensures that the propellers spin in opposite directions, providing balanced propulsion and preventing torque steer.

- Right-Hand Engine + Left-Hand Blower: A common configuration for standard rotation engines.

- Left-Hand Engine + Right-Hand Blower: Used for counter-rotating engines.

Versatility in Vessel Design

Shipbuilders benefited from Detroit Diesel’s dual-blower system because it allowed them to configure engines for virtually any vessel design. Whether building fishing boats, tugboats, or luxury yachts, marine engineers could count on Detroit Diesel engines to meet their propulsion requirements without requiring extensive customization.

Support for Auxiliary Systems

In addition to main propulsion, Detroit Diesel engines were used for auxiliary systems on vessels, such as powering winches, pumps, or onboard generators. These systems often had unique installation constraints that required specific blower orientations. By offering both options, Detroit Diesel ensured that their engines could seamlessly integrate into any marine application.

4. Ease of Maintenance and Repairs

Maintenance and repairability were key factors in Detroit Diesel’s design philosophy. By offering standardized right-hand and left-hand blowers, the company made it easier for customers to maintain their engines and replace parts.

Simplified Maintenance

Engine operators and mechanics could replace blowers without needing to modify the engine’s rotation or make extensive changes to the engine’s configuration. This simplicity reduced downtime and ensured that engines could be quickly restored to working condition.

Cost Savings

Standardized blower designs reduced the need for custom solutions, which could be expensive and time-consuming. This was particularly beneficial for fleet operators who needed to maintain multiple engines efficiently.

Global Support

Detroit Diesel’s widespread presence meant that customers around the world could access replacement parts for both right-hand and left-hand blowers. This global support network further cemented the company’s reputation for reliability and customer service.

5. Versatility Across Industries

The Detroit Diesel Inline 71 Series was designed to serve a wide range of industries, each with unique installation requirements. The availability of dual blower orientations made these engines highly versatile and adaptable.

Industrial Equipment

Industrial applications often involved space constraints or unusual mounting configurations. Right-hand and left-hand blowers allowed these engines to fit seamlessly into equipment such as cranes, compressors, and drilling rigs.

Military Applications

Detroit Diesel engines were widely used in military vehicles and equipment, where flexibility and reliability were paramount. Complex configurations often required dual blower options to ensure proper performance in diverse operating conditions.

Stationary Power Units

For stationary applications such as generators or pumps, engine orientation could vary based on the equipment’s layout. Offering both right-hand and left-hand blowers allowed Detroit Diesel engines to adapt to these setups without requiring extensive modifications.

Adaptability as a Competitive Advantage

By providing dual blower options, Detroit Diesel ensured their engines could meet the demands of any industry or application. This adaptability contributed to the enduring popularity of the 71 Series and helped the company maintain its position as a leader in the diesel engine market.

Conclusion

The decision to produce both right-hand and left-hand blowers for the Detroit Diesel Inline 71 Series engines highlights the company’s commitment to versatility, performance, and adaptability. By accommodating a wide range of applications and configurations, Detroit Diesel ensured that their engines could be seamlessly integrated into any setup, from twin-engine marine systems to industrial equipment.

This innovative approach not only cemented the 71 Series as a reliable and durable engine line but also contributed to its enduring popularity across multiple industries. Whether you’re maintaining a marine vessel or an industrial generator, understanding the importance of blower orientation can help you appreciate the engineering foresight of Detroit Diesel.

Parts Catalog for Detroit Diesel 371 Non Turbo (2 Valve Head Type)

Parts Catalog for Detroit Diesel 371 Non Turbo (4 Valve Head Type)

Parts Catalog for Detroit Diesel 471 Non – Turbo (2 Valve Head Type)

Parts Catalog for Detroit Diesel 471 Non Turbo (4 valve Head Type)

Parts Catalog for Detroit Diesel 671 Non Turbo (2 Valve head Type)

Parts Catalog for Detroit Diesel 671 Non Turbo (4 Vale Head Type)

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588