Installing Your Cylinder Head For Your Cummins Engine

Installing a cylinder head for a Cummins engine can be an intimidating task. The cylinder head and head components are critical parts which keeps your engine running efficiently. To properly install a cylinder head, it is important to have the right tools and the right parts. This guide will provide you with a step-by-step process for installing your new cylinder head.

Remove Your Old Cylinder Head

The first step in installing a cylinder head is to remove the old one. This can be done by disconnecting the fuel lines, vacuum lines, and other components from the engine. Once these components have been disconnected, the old cylinder head can be removed. It is important to use caution and take your time during this process to ensure that no components are damaged.

Remove Old Gaskets From The Engine

Next, the old gasket should be removed from the engine. This can be done by using a gasket scraper or a razor blade to carefully remove the old gasket from the engine block. The old gasket should be discarded, as it can no longer be used.

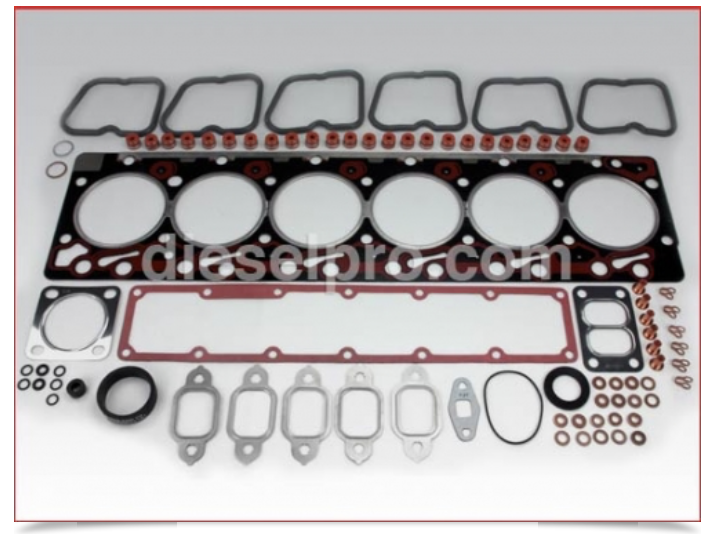

Install Your Cummins Upper Gasket Set Or “Head Gasket Set”

Once the old gasket has been removed, the new gasket should be applied to the engine block. It is important to take your time and make sure that the gasket is properly applied to the engine block.

Below is a list of Cummins Upper Gasket Sets:

Cummins 4B Upper Gasket Set Oversize 0.25mm

Cummins 4BT Upper Gasket Set Oversize 0.25mm

Cummins 4BTA Upper Gasket Set Oversize 0.25mm

Cummins 6B Upper Gasket Set Oversize 0.25mm

Cummins 6BT Upper Gasket Set Oversize 0.25mm

Cummins 6BTA Upper Gasket Set Oversize 025mm

Cummins ISB 4.5 L Upper Gasket Set

Cummins ISB 5.9L Upper Gasket Set (Non EGR Engines)

Cummins ISB 5.9L Upper Gasket Set (EGR Engines)

Cummins ISB 6.7L Upper Gasket Set

Cummins QSB 4.5 L Upper Gasket Set

Cummins QSB 5.9L Upper Gasket Set (EGR Engines)

Cummins QSB 5.9L Upper Gasket Set (Non-EGR Engines)

Cummins QSB 6.7L Upper Gasket Set

Cummins ISC Upper Gasket Set For engines with CM554, CAPS fuel system

Cummins ISC Upper Gasket Set For Engines With For engines with CM850, HPCR fuel system

Cummins ISC Upper Gasket Set For EGR Engines

Cummins QSC Upper Gasket Set For Engines With CM554, CAPS fuel system

Cummins QSC Upper Gasket Set For Engines With CM850, HPCR fuel system

Cummins QSC Upper Gasket Set For Engines With CM850, HPCR fuel system

Cummins QSC Upper Gasket Set For EGR Engines

Cummins ISL Upper Gasket Set For Engines With CM554, CAPS fuel system

Cummins ISL Upper Gasket Set For Engines With CM850, HPCR fuel system

Cummins ISL Upper Gasket Set For Engines With EGR

Cummins QSL Upper Gasket Set For engines with CM554, CAPS fuel system

Cummins QSL Upper Gasket Set For Engines with CM850, HPCR fuel system

Cumins NH 855 Upper Gasket Set

Cummins NT 855 Upper Gasket Set

Cummins N14 Upper Gasket Set For CELECT engines only

Cummins ISX Upper Gasket Set For Non EGR Engines

Cummins ISX Upper Gasket Set For EGR Engines

Cummins QSX Upper Gasket Set For Non EGR Engines

Cummins QSX Upper Gasket Set For EGR Engines

Cummins KTA19 Upper Gasket Set For Turbo After Cooled Engines

Cummins KTA38 Upper Gasket Set

Cummins KTA50 Upper Gasket Set

Cummins QSK19 Upper Gasket Set

Install Your Cummins Cylinder Head

The next step in the process is to install the new cylinder head. This is done by carefully placing the head onto the engine block and ensuring that all of the mounting bolts are properly secured. Once the head is in place, the head bolts should be tightened to the manufacturer’s specifications.

Once the cylinder head is securely in place, the remaining components should be re-connected. This includes the fuel lines, vacuum lines, and other components. It is important to make sure that all of the components are properly connected to avoid any engine damage.

The final step in the process is to check the engine for any leaks. This can be done by using a pressure tester to check for any leaks in the cylinder head or other components. If there are any leaks, they should be fixed before the engine is started.

Should I Replace The Head Bolts Every Time I Replace The Cylinder Head?

Yes, head bolts should be replaced every time when you replace your cylinder head.

Below Is A List Of Cummins Cylinder Heads

Cylinder Head For Cummins 4B Engine New – with valves and springs and comes with 9mm injector tubes

Cylinder Head For Cummins 4BT Engine New – with valves and springs and comes with 9mm injector tubes

Cylinder Head For Cummins 4BTA New – head with valves and springs. Comes with 7mm injector tubes

Cylinder Head For Cummins 4BTA New – with valves and springs and comes with 9mm injector tubes

Cylinder Head For Cummins 6B New – head with valves and springs. Comes with 7mm injector tubes

Cylinder Head For Cummins 6B New – with valves and springs. For marine application only

Cylinder Head For Cummins 6BT New – head with valves and springs. Comes with 7mm injector tubes

Cylinder Head For Cummins 6BT New – with valves and springs. For marine application only

Cylinder Head For Cummins 6BTA New – head with valves and springs. Comes with 7mm injector tubes

Cylinder Head For Cummins 6BTA New – with valves and springs. For marine application only

Cylinder Head For Cummins ISB 5.9L With Valves & Springs

Cylinder Head For Cummins ISB 6.7L With Valves & Springs

Cylinder Head For Cummins QSB 5.9 New – head with valves and springs. Marine application

Cylinder Head For QSB 6.7 With Valves & Springs

Cylinder Head For Cummins QSB 6.7 With Valves & Springs

Cylinder Head For Cummins 6C New with valves and 16″ air intake

Cylinder Head For Cummins 6C New with valves and 21″ air intake

Cylinder Head For Cummins 6C New – with valves. For marine application, 2 valves per piston

Cylinder Head For Cummins 6CT New with valves and 16″ air intake

Cylinder Head For Cummins 6CT New with valves and 21″ air intake

Cylinder Head For Cummins 6CT New – with valves. For marine application, 2 valves per piston

Cylinder Head For Cummins 6CTA New with valves and 16″ air intake

Cylinder Head For Cummins 6CTA New with valves and 21″ air intake

Cylinder Head For Cummins 6CTA New – with valves. For marine application, 2 valves per piston

Cylinder Head For Cummins ISC With Valves & Springs

Cylinder Head For Cummins QSC With Valves & Springs

Cylinder Head For Cummins ISL With Valves & Springs

Cylinder Head For Cummins QSL With Valves & Springs

Cylinder Head For Cummins QSL With Valves & Springs

Cylinder Head For Cummins M11 With Valves & Springs

Cylinder Head For Cummins ISM With Valves & Springs

Cylinder Head For Cummins QSM With Valves & Springs

Cylinder Head For Cummins QSM New – with valves and springs Marine application only

Cylinder Head For Cummins NH 855 With Valve & Springs

Cylinder Head For Cummins NT855 With Valve & Springs

Cylinder Head For Cummins N14 With Valve & Springs

Conclusion

Installing a cylinder head for a Cummins engine is not an easy task. However, with the right tools, parts, and knowledge, it can be accomplished. Following the steps outlined in this guide will ensure that the job is done properly and that your engine will run efficiently and reliably.

Although the process of installing a cylinder head can be intimidating, it is an essential part of keeping your engine running efficiently and reliably. With the right tools and knowledge, installing a cylinder head can be an easy and rewarding task.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588