Detroit Diesel Series 149 Overview (8V149, 12V149, 16V149)

The Detroit Diesel Series 149 engines are robust two-cycle, V-type diesel engines designed to deliver high power and reliability across demanding applications. They feature a unique two-stroke cycle with an integrated air scavenging system, optimized for sustained, high-performance operation. This configuration provides a favorable weight-to-horsepower ratio, making them ideal for heavy-duty use in various settings.

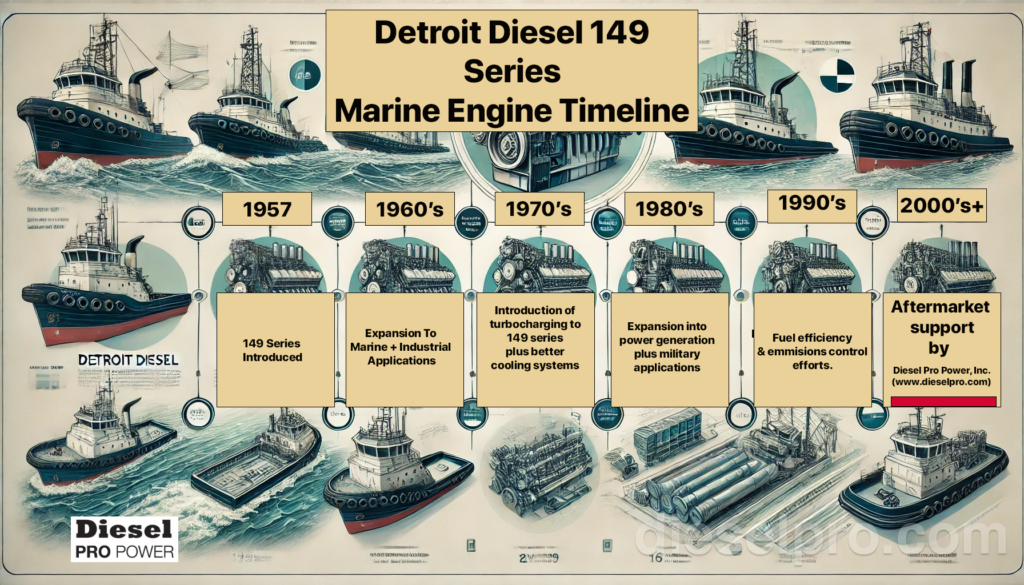

History and Development

Initially developed to meet the high demands of the industrial and marine sectors, Series 149 engines have established a strong reputation in multiple industries due to their efficiency and adaptability. Detroit Diesel engineered these engines to meet the rigorous needs of heavy-duty transport and industrial equipment, making them popular choices for sectors like marine propulsion, off-highway vehicles, and high-powered industrial applications.

Applications

- Marine:

The Series 149 engines are particularly favored in marine settings, where reliability and continuous operation are critical. With models equipped for either naturally aspirated or turbocharged configurations, they are suitable for various marine vessels, from small boats to large ships. The cooling systems in these engines are designed to withstand prolonged exposure to seawater and other harsh marine conditions, enhancing durability in saltwater environments.

- Industrial:

In industrial applications, Series 149 engines power equipment that requires both sustained power output and the ability to operate in extreme conditions. Their high torque and power capabilities make them suited for construction and mining machinery, where engines often face heavy loads and varying terrain. The engines’ robust construction and efficient cooling systems allow them to maintain performance under strenuous, full-load conditions without compromising reliability.

- Trucking and Off-Highway Vehicles:

These engines are also implemented in off-highway vehicles such as mining trucks and loaders, where heavy-duty performance is essential. Designed to endure demanding usage cycles, the Series 149 offers consistent power, even in off-road and high-altitude environments. Its efficient fuel system, complemented by high-capacity injectors and turbocharging options, provides the necessary output for large vehicles carrying heavy loads across challenging terrains.

Key Features

The Series 149 engines incorporate several design features tailored for ease of maintenance and operational longevity:

- Two-Cycle Operation:

The engine’s two-stroke cycle provides a simpler yet efficient combustion process, delivering high power output with fewer moving parts.

- Scavenging Air System:

A built-in blower supplies the necessary airflow for combustion, which is especially critical for maintaining power in high-load scenarios.

- Durable Construction:

The engines are built with individual cylinder heads and free-floating pistons, enabling easier serviceability and enhancing the durability of each cylinder assembly.

- High Power Density:

Designed with multiple configurations (8V, 12V, 16V), these engines can meet a wide range of power needs with flexible setups for different applications.

Importance of Maintenance For The Detroit Diesel 149 Series Engines (8V149, 12V149, 16V149)

Proper maintenance is crucial for ensuring the longevity and reliability of the Detroit Diesel Series 149 engines. Regular upkeep of key systems like lubrication, cooling, and fuel is essential for preventing wear, optimizing performance, and reducing the risk of unexpected failures.

How Maintenance Supports Longevity

Consistent maintenance extends the engine’s operational life by preserving essential components and preventing damage from common issues. Each component—from the lubrication system to the air cleaner—requires routine checks to maintain proper function, which helps avoid excessive wear on internal parts such as the piston rings, bearings, and valves. Neglecting these tasks can lead to build-up of contaminants, inadequate cooling, and eventual component failure.

Reliability through Preventive Maintenance

Preventive maintenance on components like the turbocharger, battery, and cooling system ensures that each part operates effectively under demanding conditions. Regular inspection of hoses, for example, prevents leaks that could lead to performance losses and safety hazards. Components such as the fan hub, thermostat, and air cleaner require specific maintenance intervals to maintain efficient operation. Routine replacement of parts with known service life limitations, like hoses and belts, further supports reliability by reducing the risk of failures during operation.

Maintenance Intervals and Best Practices

The Series 149 manual outlines detailed maintenance intervals for critical components:

- Daily Checks: Oil levels, fuel lines, and cooling system should be checked each shift to catch immediate issues early.

- Regular Intervals (e.g., 300, 600, and 1,000 hours):

Components such as air cleaners, fuel filters, and turbochargers should be inspected and serviced to sustain performance.

- Long-Term Overhauls (5,000 hours):

For more durable components, major tune-ups and overhauls are recommended to refresh the engine and prevent extensive wear.

This structured approach not only supports consistent performance but also minimizes downtime, which is especially valuable in high-stakes applications like marine and industrial settings.

Challenges Due to Out-of-Print Manual For The Detroit Diesel 149 Series Engines (8V149, 12V149, 16V149) & How Diesel Pro Power, Inc’s Guides Can Help You

Owners and operators of the Detroit Diesel 149 Series engines (8V149, 12V149, and 16V149) face unique challenges due to the manual being out of print. This engine series is highly regarded for its durability and power, yet without an easily accessible manual, keeping these engines in peak condition can be difficult. While Detroit Diesel engines are known for their longevity, proper maintenance and repair become challenging when essential instructions, specifications, and troubleshooting guides are unavailable. We put together a guide with key insights from the now out of print manual.

Focus on Practical Use For The Detroit Diesel 149 Series Engines (8V149, 12V149, 16V149):

This guide is designed to provide owners and operators with a high-level overview and step-by-step maintenance tips for essential tasks on Detroit Diesel 149 Series engines, including models 8V149, 12V149, and 16V149. While this guide aims to simplify routine maintenance and highlight critical steps, it does not replace professional advice or the detailed specifications found in the original manual. Instead, the focus is on practical, hands-on insights for keeping these engines in reliable working order.

How This Guide Supports Practical Maintenance

This guide condenses key maintenance and troubleshooting practices into accessible steps for everyday use. For technicians and operators who frequently work with these engines, it serves as a quick reference to ensure vital tasks are completed correctly. Covering everything from routine inspections to common adjustments, this guide is intended to bridge knowledge gaps and provide easy-to-follow instructions on:

- Daily Inspections:

Tips on quickly checking oil levels, coolant levels, and inspecting for fuel leaks or loose connections. These checks ensure any immediate issues are identified early, preventing minor problems from escalating into costly repairs.

- Regular Adjustments and Tune-Ups:

An overview of important adjustments, such as injector timing and valve clearance, with reminders on interval-based tasks. Precise injector timing and accurate valve adjustments are necessary to maintain fuel efficiency and avoid issues like rough idling or misfires. This guide offers a simplified process for making these adjustments, reminding users of the importance of precision.

- Cleaning and Replacing Filters:

Regular filter maintenance, including fuel, oil, and air filters, is essential to keeping the engine free from contaminants. This guide provides straightforward steps for replacing these filters and indicates how often each should be replaced. Clean filters not only support smoother operation but also protect sensitive components from potential damage.

- Cooling System Maintenance:

Instructions on maintaining the cooling system to prevent overheating, including flushing intervals, checking coolant quality, and inspecting hoses and pumps for wear. The guide emphasizes monitoring coolant levels daily, performing flushes on schedule, and keeping an eye out for leaks or blockages that could lead to overheating.

- Basic Troubleshooting Tips:

Quick troubleshooting steps for common issues such as excessive exhaust smoke, engine knocking, or overheating. Each symptom includes a list of possible causes and basic solutions, helping operators quickly identify whether they need a simple adjustment or more extensive repairs.

Encouraging Professional Expertise for Complex Repairs

While this guide is valuable for routine maintenance, it is important to emphasize that complex repairs, in-depth overhauls, and precision adjustments are best handled by professional technicians or with access to detailed specifications. For example:

- Advanced Component Replacements:

Detailed procedures for removing and replacing parts like pistons, crankshafts, or camshafts are complex and require specialized tools and training. This guide will advise owners on when to seek professional help rather than attempting these repairs independently.

- High-Precision Adjustments:

Tasks requiring exact measurements, such as injector timing adjustments with fine tolerances or valve seating refinements, benefit from specialized equipment. Professionals with the appropriate tools and expertise ensure these adjustments are within factory specifications.

- Diagnostic Tools:

Some engine issues may require diagnostic tools to properly assess fuel injection systems, electrical components, or emissions. Professional service centers have access to these tools, enabling them to provide a more thorough analysis of complex problems.

By providing a practical, user-friendly approach to everyday maintenance tasks, this guide empowers owners and operators to confidently manage routine upkeep on their Detroit Diesel 149 engines. It serves as an essential companion for hands-on maintenance, while also acknowledging the role of professional expertise in handling intricate repairs and diagnostics. Through this approach, operators can ensure their engines remain reliable and efficient, while also knowing when to rely on expert advice for more complex issues.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588