Overview of Lubricating System

The lubrication system is essential for the longevity and efficiency of the Detroit Diesel Series 60 engine. It ensures smooth operation by minimizing friction, reducing heat, and protecting components from wear and contamination.

Parts Catalog for 11.1L Detroit Diesel 60 Series Marine Engine

Parts Catalog for 12.7L Detroit Diesel 60 Series Marine Engine

Parts Catalog for 14L Detroit Diesel 60 Series Marine Engine

Diagram of Oil Flow and Critical Lubrication Points

Oil flows from the sump through the oil pump to the oil filters and cooler, eventually reaching the main oil gallery. From there, it is distributed to critical engine parts:

- Crankshaft and Bearings: Provide lubrication and cooling to the main and connecting rod bearings.

- Camshaft and Rocker Arms: Lubricate valve actuators, cams, and associated parts.

- Turbocharger: Ensures adequate lubrication and cooling of high-speed bearings.

- Piston Cooling Jets: Spray oil onto piston undersides for cooling and lubrication.

Diagram of flow can illustrate:

- Oil Pump → Oil Filters → Oil Cooler → Main Gallery → Bearings → Return to Sump.

Key Components Ensuring Proper Lubrication

- Oil Pump: Draws oil from the sump and pressurizes it for distribution.

- Filters: Remove contaminants from the oil, ensuring cleanliness.

- Oil Cooler: Maintains optimal oil temperature by dissipating heat.

- Relief Valves: Regulate oil pressure to prevent damage from overpressurization.

- Thermatic Oil Control Valve: Controls oil flow through the cooler based on temperature.

Proper maintenance of these components is vital to avoid engine failures caused by overheating or inadequate lubrication.

Oil Pump and Pressure Regulation

The oil pump is a gear-driven component that pressurizes the lubrication system, while relief valves ensure the pressure stays within operational limits.

Maintenance of the Oil Pump and Pressure Relief Valves

- Inspection:

- Remove the oil pump during major services and inspect for wear.

- Check gears, shafts, and bushings for signs of damage or wear.

- Cleaning:

- Disassemble the pump and clean components in solvent to remove sludge or debris.

- Dry thoroughly with compressed air before reassembly.

- Reassembly:

- Replace worn gears, bushings, or seals.

- Torque bolts to specifications during reinstallation.

Adjusting and Testing Oil Pressure Settings

- Testing:

- Use a pressure gauge at the oil pressure port to verify operational pressure.

- Ideal pressure range for Series 60 engines is 40–60 psi at normal operating temperature.

- Adjustment:

- If pressure is too high or too low, check the relief valve spring for wear or damage.

- Replace the spring or valve if necessary to restore proper regulation.

- Verification:

- After adjustments, retest pressure and ensure no leaks are present.

- After adjustments, retest pressure and ensure no leaks are present.

Pro Tip: Always use manufacturer-approved seals and components to avoid leaks or pressure inconsistencies.

Thermatic Oil Control Valve

The thermatic oil control valve ensures optimal engine performance by regulating oil flow to the cooler. It modulates based on oil temperature, preventing overcooling during startups and ensuring proper cooling during high-load operation.

Controlling Oil Temperature for Optimal Engine Performance

- Functionality:

- At temperatures below 220°F, the valve bypasses the oil cooler, allowing oil to warm quickly.

- As the temperature rises, the valve opens, directing oil through the cooler to maintain temperatures within 220°F–237°F.

- Benefits:

- Faster warm-ups reduce engine wear during cold starts.

- Consistent oil temperatures improve lubrication efficiency and reduce fuel consumption.

Diagnosing and Replacing Faulty Thermatic Valves

- Symptoms of a Faulty Valve:

- Overheating or underheating of engine oil.

- Fluctuating oil pressures or delayed warm-up times.

- Diagnosis:

- Remove the valve and test its operation by immersing it in heated oil.

- The valve should start opening at 220°F and fully open at 237°F.

- Replacement Steps:

- Drain the oil and remove the oil filter adaptor.

- Replace the thermatic valve with a new component, ensuring proper seating.

- Reinstall the filter adaptor and refill the oil to the correct level.

Pro Tip: Lubricate the valve seals lightly with petroleum jelly before installation to prevent damage during seating.

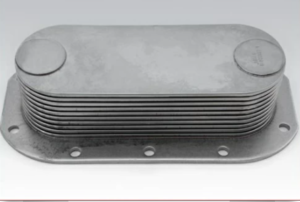

Oil Coolers (1991 and Later Models)

Oil coolers are critical for maintaining the proper oil temperature and protecting the engine under heavy loads. They ensure the lubricating oil does not overheat, preserving its viscosity and effectiveness.

Importance of Maintaining Proper Oil Cooling

- Heat Dissipation:

- Oil absorbs heat from engine components and must be cooled before recirculation.

- An efficient cooler prevents excessive oil temperatures that degrade lubrication quality.

- Preventing Contamination:

- Coolers with leaks can allow coolant or contaminants to mix with oil, leading to engine damage.

- Coolers with leaks can allow coolant or contaminants to mix with oil, leading to engine damage.

Step-by-Step Guide for Cleaning, Testing, and Replacing Oil Coolers

- Cleaning:

- Remove the cooler and submerge it in a cleaning solution like Tech Solv 340.

- Flush the cooler with clean water to remove residue and debris.

- Testing:

- Cap one end of the cooler and pressurize it with air (75–100 psi).

- Submerge the cooler in water and watch for bubbles, which indicate leaks.

- Replacement:

- If leaks are detected, replace the cooler core with a new component.

- Install new gaskets and O-rings to ensure a proper seal.

- Torque cooler housing bolts to specifications during reinstallation.

- Final Steps:

- Reconnect hoses and refill the cooling system with the appropriate coolant.

- Start the engine and verify oil pressure and temperature readings are within normal ranges.

Pro Tip: Always use fresh coolant and oil after cooler replacement to avoid contamination.

By maintaining the lubrication system in optimal condition, technicians can extend the life of the Detroit Diesel Series 60 engine and ensure consistent performance under demanding conditions. Proper care of oil pumps, valves, and coolers prevents costly repairs and downtime.

Parts Catalog for 11.1L Detroit Diesel 60 Series Marine Engine

Parts Catalog for 12.7L Detroit Diesel 60 Series Marine Engine

Parts Catalog for 14L Detroit Diesel 60 Series Marine Engine

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588