Marine CAT C9 Coolant System Specific Component Maintenance Life

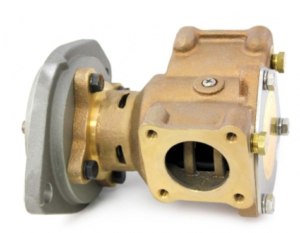

Engine Water Pump for Caterpillar C9

Please note that these are typical maintenance intervals for the Marine CAT C9 engine’s coolant system components, and some results may vary based on operating conditions. Adhering to these schedules is essential for ensuring reliable performance and extending the engine’s operational life.

Component |

Maintenance Interval (Hours) |

Notes |

| Coolant | 1,000 hours | Change to maintain optimal cooling and prevent corrosion in the system. |

| Freshwater Pump | 2,000-3,000 hours | Inspect for leaks, wear, and corrosion; replace seals or rebuild as necessary. |

| Raw Water Pump | 500-1,000 hours | Inspect the impeller for wear; replace the impeller and seals as needed to maintain proper cooling. |

| Thermostats | 1,500-2,000 hours | Inspect and test; replace if malfunctioning or during major coolant system service. |

Maintaining these components according to the recommended intervals is crucial for the reliable operation of the CAT C9 engine, particularly in marine environments. Regular inspections and timely servicing help extend the engine’s life and minimize the risk of unexpected failures.

Disclaimer: The most accurate data for each specific engine will always be found in the OEM service manual. The numbers provided here are estimates and can vary based on operating conditions. Factors such as inadequate cooling, lubrication, or fuel quality issues can affect other engine components, potentially altering maintenance intervals. Engine components are interconnected, so one issue can impact others, leading to different service needs. Always tailor your maintenance approach to the specific conditions in which your engine operates.

Engine Specifications & Applications of the Caterpillar C9 Engine

Overview of the Caterpillar C9

The Caterpillar C9 is a 6-cylinder, 8.8-liter inline diesel engine designed to deliver reliable mid- to high-power performance for heavy-duty off-highway, industrial, and generator applications. Introduced as part of the ACERT (Advanced Combustion Emissions Reduction Technology) family, the C9 filled the horsepower gap between the C7 and larger C13, offering superior torque delivery, efficient fuel burn, and dependable emissions control in demanding duty cycles.

The C9 gained wide adoption in the early 2000s across Tier 3 and Tier 4 Interim regulated markets and is still used in many export and repower applications today. Its combination of electronic fuel injection, robust turbocharging, and durable internals has made it a workhorse in sectors ranging from construction and power generation to mining and oilfield operations.

Though production of new C9 engines for on-highway use has ceased, the platform remains widely supported in aftermarket installations, repowers, and industrial machinery around the world.

Caterpillar C9 Engine Specifications

|

Specification |

Details |

|

Engine Configuration |

Inline 6-cylinder, 4-stroke diesel |

|

Displacement |

8.8 Liters (537 cubic inches) |

|

Bore x Stroke |

112 mm x 149 mm |

|

Compression Ratio |

16.0:1 |

|

Aspiration |

Turbocharged and Aftercooled |

|

Power Output Range |

275 – 375 HP (205 – 280 kW) @ 2,200 RPM |

|

Peak Torque |

Up to 1,250 lb-ft (1,695 Nm) @ 1,400 RPM |

|

Fuel System |

HEUI (Hydraulic Electronic Unit Injection) or Common Rail |

|

Emissions Compliance |

Tier 3 / Tier 4 Interim / Euro III |

|

Aftertreatment (where required) |

DOC or DOC + DPF (varies by application) |

|

ECM and Control |

ADEM III / ADEM IV Electronic Control |

|

Cooling System |

Water-cooled via radiator or remote cooling loop |

|

Dry Weight |

Approx. 2,100–2,400 lbs (950–1,090 kg) |

|

Oil Capacity |

28 – 36 liters depending on sump configuration |

|

Fuel Consumption |

~0.34–0.36 lb/hp-hr under load |

Applications of the Caterpillar C9 Engine

The Caterpillar C9’s powerful output, advanced fuel system, and electronic engine management make it suitable for high-demand environments. Its versatility is demonstrated by its use in construction equipment, generator sets, oilfield machines, industrial systems, and export repowers.

1. Power Generation

One of the most prominent uses for the C9 is in diesel generator sets. With a typical genset output range of 175–300 kW, the C9 is suited to both prime and standby applications in harsh environments.

Generator Applications:

-

Standby power for hospitals, banks, and commercial buildings

-

Prime power for construction sites, data centers, and remote camps

-

Mobile power units and containerized gensets

-

Export units for Tier 3 markets or regions with no emissions regulation

-

Industrial backup systems and remote pumping stations

Its reliability, combined with a steady power curve and remote monitoring capability, makes it ideal for mission-critical power systems.

2. Construction & Heavy Equipment

The C9 is widely used in large construction machines where mid- to high-horsepower output is needed without the bulk of a larger displacement engine.

Common Machinery:

-

Excavators in the 30–40 ton range

-

Wheel loaders and motor graders

-

Articulated dump trucks

-

Trenchers and directional boring machines

-

Soil compactors and roadbuilding equipment

Its torque-rich characteristics help drive hydraulic systems and propulsion in demanding terrain and climate conditions.

3. Oilfield & Mining Equipment

The Caterpillar C9 has been a mainstay in energy-sector and mining support equipment. With durability under continuous duty and the ability to withstand heavy particulate loads, it’s often found in oil patch and quarry environments.

Use Cases:

-

Frac pump power units

-

Coil tubing injectors

-

Mud pumps and cementing skids

-

Conveyor drives in open-pit mining

-

Dust suppression and blasting support equipment

Its serviceability and cooling system design make it especially suitable for extreme-duty applications in hot, dusty, or corrosive environments.

4. Industrial & Stationary Equipment

The C9’s robust architecture supports a wide range of industrial tasks that demand continuous runtime and efficient fuel burn.

Typical Installations:

-

Large hydraulic power units

-

Mechanical drive systems for dredging and barge loading

-

Stationary water pumps and firefighting engines

-

Material handling cranes

-

Diesel-powered compressors and refrigeration units

Because of its adaptable mounting and ECM control, the C9 can be easily integrated into both custom-engineered and OEM platforms.

5. Marine Auxiliary Use

The C9 is used in marine generator sets and auxiliary drives, especially in commercial workboats and dredging vessels.

Marine Applications:

-

Shipboard gensets (200–300 kW)

-

Fire pump engines

-

Hydraulic power sources for winches, cranes, or steering

-

Bilge and fuel transfer systems

-

Deck machinery power

Its compact footprint relative to output makes it valuable in space-restricted engine rooms, and aftermarket support is strong in both coastal and inland waterways.

6. Global Repower and Export Markets

The Caterpillar C9 remains in high demand in repower and resale markets, especially in Latin America, Africa, Southeast Asia, and the Middle East, where Tier 3 and Tier 4 Interim engines are still accepted.

Repower Scenarios:

-

Replacement of 3306, 3176, or early C10 engines

-

Updating gensets to more efficient Tier 3 platforms

-

Export of trailer-mounted pump skids and utility equipment

-

Retrofitting aging equipment for industrial fleet modernization

-

Refurbishing municipal or emergency response machinery

Its wide emissions tier coverage and availability in both electronic and semi-mechanical formats give it exceptional retrofit flexibility.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588