The Cummins QSC 8.3L marine diesel engine stands as a cornerstone in marine propulsion, blending cutting-edge technology with robust durability. This six-cylinder powerhouse is an ideal choice for operators seeking reliability, efficiency, and optimal performance in demanding marine environments. Whether you’re navigating open seas or powering through challenging waters, the QSC 8.3L delivers the dependability that Cummins engines are renowned for.

Please note that these are typical maintenance intervals for the Marine Cummins QSC engine, and some results may vary based on operating conditions. Adhering to these schedules is essential for ensuring reliable performance and extending the engine’s operational life.

Marine Cummins QSC Component Maintenance Life

Component |

Maintenance Interval (Hours) |

Notes |

| Oil and Filter Change | 250 hours | Regular oil changes are essential for maintaining lubrication and preventing wear. |

| Fuel Filters | 500 hours | Replace to ensure clean fuel and prevent injector issues. |

| Air Filters | 500 hours | Inspect regularly; replace when dirty to protect the engine. |

| Coolant | 1,000 hours | Change to maintain cooling efficiency and prevent corrosion. |

| Injectors | 2,000 hours | Inspect, clean, or replace to ensure proper fuel delivery and combustion. |

| Valve Adjustment | 1,500 hours | Regular adjustments help maintain engine timing and performance. |

| Turbocharger Inspection | 2,000-3,000 hours | Inspect for wear; service or replace if necessary to maintain boost pressure. |

| Cylinder Head Overhaul | 4,000-5,000 hours | Overhaul to address wear, cracks, and sealing issues. |

| Piston Rings | 6,000 hours | Replace during major overhauls to maintain compression and reduce oil consumption. |

| Crankshaft Bearings | 6,000-8,000 hours | Inspect during overhauls; replace if signs of wear are detected. |

| Complete Engine Overhaul | 10,000-12,000 hours | Comprehensive overhaul including pistons, liners, bearings, and other major components. |

Marine Cummins QSC Coolant System Specific Component Maintenance Life

Component |

Maintenance Interval (Hours) |

Notes |

| Coolant | 1,000 hours | Change to maintain optimal cooling and prevent corrosion in the system. |

| Freshwater Pump | 2,000-3,000 hours | Inspect for leaks, wear, and corrosion; replace seals or rebuild as necessary. |

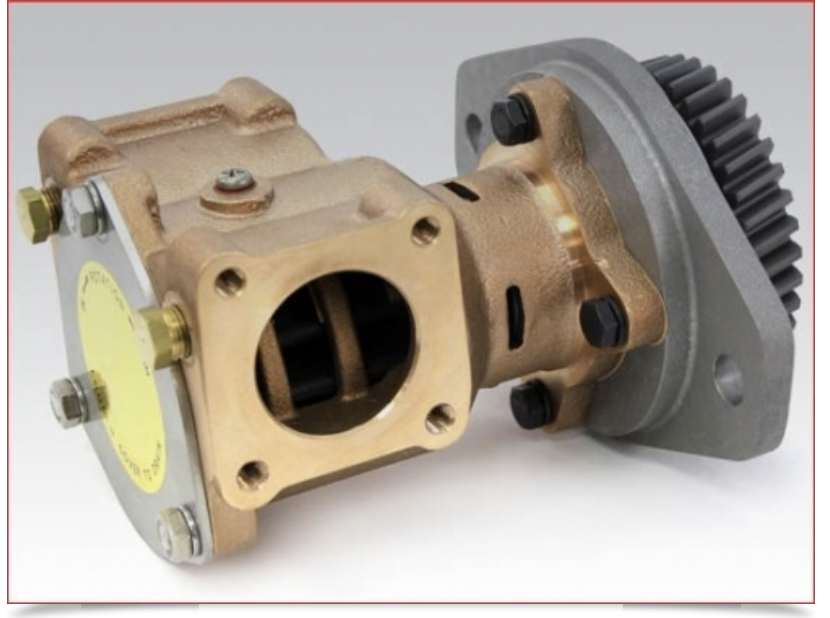

| Raw Water Pump | 500-1,000 hours | Inspect impeller for wear; replace impeller and seals as needed to maintain proper cooling. |

| Thermostats | 1,500-2,000 hours | Inspect and test; replace if malfunctioning or during major coolant system service. |

Regular maintenance according to these intervals is crucial for the reliable performance of the Cummins QSC engine in marine applications. Consistent inspections and servicing help extend the engine’s life and minimize the risk of unexpected failures.

Disclaimer: The most accurate data for each specific engine will always be found in the OEM service manual. The numbers provided here are estimates and can vary based on operating conditions. Factors such as inadequate cooling, lubrication, or fuel quality issues can affect other engine components, potentially altering maintenance intervals. Engine components are interconnected, so one issue can impact others, leading to different service needs. Always tailor your maintenance approach to the specific conditions in which your engine operates.

Overview of the Cummins QSC 8.3L

The Cummins QSC 8.3L is a turbocharged, electronically controlled engine designed for marine applications. Part of the Quantum System series, the QSC 8.3L features advanced fuel systems and diagnostic capabilities, ensuring superior efficiency and simplified maintenance.

Key Features of the Cummins QSC 8.3L

- Electronic Control Module (ECM)

The ECM provides precise control over fuel delivery and timing, optimizing engine performance and fuel efficiency while minimizing emissions.

- High Power-to-Weight Ratio

The QSC 8.3L’s design delivers impressive power output without compromising on weight, making it an excellent choice for various vessel types.

- Advanced Fuel System

The high-pressure common rail (HPCR) fuel system ensures cleaner combustion, reduced noise, and improved fuel economy.

- Durability and Corrosion Resistance

With marine-grade materials and coatings, the QSC 8.3L is built to withstand the harsh conditions of saltwater environments.

Applications of the Cummins QSC 8.3L in Marine Settings

The versatility of the Cummins QSC 8.3L makes it suitable for a wide range of marine applications:

-

Commercial Fishing Boats

The QSC 8.3L’s reliability and fuel efficiency are critical for extended fishing trips where downtime is not an option.

-

Workboats and Tugs

Its high torque and robust construction make the QSC 8.3L ideal for towing, maneuvering, and heavy-duty applications.

-

Recreational Yachts

With smooth operation and impressive performance at varying speeds, the QSC 8.3L is a favorite among yacht owners seeking comfort and efficiency.

-

Passenger Vessels

Operators of ferries and passenger boats benefit from the engine’s quiet operation, fuel efficiency, and low maintenance requirements.

Maintenance Guidelines for the Cummins QSC 8.3L

Regular maintenance is crucial to keep your Cummins QSC 8.3L engine performing at its best. Following a consistent maintenance schedule can extend the engine’s lifespan, enhance reliability, and reduce operational costs.

Key Maintenance Practices

- Oil and Filter Changes

- Replace the oil and oil filter every 250 hours or according to the manufacturer’s recommendations.

- Use high-quality marine-grade oil to reduce engine wear and maintain optimal lubrication.

- Cooling System Maintenance

- Regularly inspect and clean the heat exchanger and raw water pump to prevent scale buildup and overheating.

- Replace the coolant as recommended to avoid corrosion and maintain proper engine temperature.

- Fuel System Care

- Replace primary and secondary fuel filters at recommended intervals.

- Use clean, high-quality marine diesel to prevent injector fouling and ensure consistent performance.

- Air System Checks

- Inspect the turbocharger and air filters regularly to ensure proper airflow and prevent loss of power.

- Inspect the turbocharger and air filters regularly to ensure proper airflow and prevent loss of power.

- Valve Adjustments

- Perform valve lash adjustments at scheduled intervals to maintain optimal engine operation.

- Perform valve lash adjustments at scheduled intervals to maintain optimal engine operation.

- Electronic Diagnostics

- Utilize the ECM’s diagnostic capabilities to monitor engine performance and identify potential issues early.

- Utilize the ECM’s diagnostic capabilities to monitor engine performance and identify potential issues early.

- Belt and Hose Inspections

- Check all belts and hoses for wear, cracks, or leaks, and replace them as needed to avoid unexpected failures.

- Check all belts and hoses for wear, cracks, or leaks, and replace them as needed to avoid unexpected failures.

Troubleshooting Common Issues

Even with proper maintenance, occasional issues may arise with the Cummins QSC 8.3L. Below are some common problems and how to address them:

-

Overheating

- Cause: Blocked cooling system, worn impeller, or low coolant levels.

- Solution: Clean the heat exchanger, inspect and replace the impeller, and refill the cooling system as necessary.

-

Black Smoke from Exhaust

- Cause: Incomplete combustion caused by dirty air filters, injector issues, or poor-quality fuel.

- Solution: Replace air filters, inspect injectors, and use high-quality fuel.

-

Loss of Power

- Cause: Turbocharger issues, clogged fuel lines, or injector malfunction.

- Solution: Check the turbocharger for damage, clean fuel lines, and replace faulty injectors.

-

Diagnostic Alarms

- Cause: ECM identifying issues such as low oil pressure or coolant temperature anomalies.

- Solution: Use the ECM diagnostics to pinpoint the issue and take corrective action promptly.

Benefits of Using Premium Aftermarket Parts for the QSC 8.3L

Maintaining your Cummins QSC 8.3L with high-quality aftermarket parts ensures long-term reliability and performance. Diesel Pro Power offers a wide range of aftermarket parts specifically designed to meet or exceed OEM standards.

Why Choose Aftermarket Parts?

- Cost Savings

Aftermarket parts are typically more affordable than OEM components, helping you manage maintenance costs without compromising quality.

- Availability

Diesel Pro Power ensures a consistent supply of parts for the QSC 8.3L, reducing downtime for your vessel.

- Modern Design Enhancements

Many aftermarket parts incorporate advanced materials and updated designs for improved durability and performance.

- Rigorous Quality Standards

Diesel Pro Power’s aftermarket parts are thoroughly tested to withstand the demands of marine applications.

Technical Specifications of the Cummins QSC 8.3L

Here are some key specifications for the Cummins QSC 8.3L engine:

- Displacement: 8.3 liters (506 cubic inches)

- Bore and Stroke: 4.49 x 5.31 inches

- Power Output: 305–600 horsepower (depending on configuration)

- Compression Ratio: 16.1:1

- Dry Weight: Approximately 1,610 lbs

These specifications highlight the QSC 8.3L’s excellent power-to-weight ratio and its ability to handle demanding marine applications effectively.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588