Parts Catalog for Twin Disc MG521 Marine Transmissions

Rebuilt Twin Disc MG521 Marine Transmissions

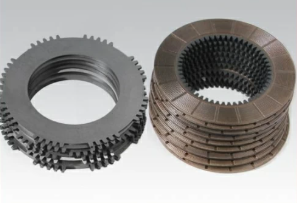

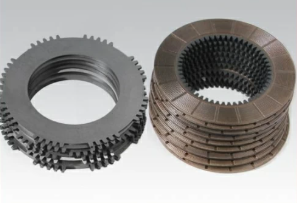

Plate Kit For Twin Disc MG521 Marine Transmission

Gasket Kits For Twin Disc MG521 Marine Transmission

The Twin Disc MG521 marine transmission is engineered for reliability and long service life, but like any heavy-duty marine component, it contains parts that wear over time and require scheduled replacement. Understanding which components need regular inspection, when to replace them, and how to ensure proper reassembly with accurate torque specifications can make the difference between smooth operation and unexpected downtime.

This guide covers the most frequently replaced parts in the MG521, including aftermarket options and premium kits offered by Diesel Pro Power. Whether you’re conducting a routine overhaul or a major service, this section provides everything you need to keep your MG521 operating at peak performance.

Common Wear Components (Clutch Plates, Seals, Bearings)

Although the MG521 is a rugged gearbox, it has moving internal components that naturally degrade over time. These parts are designed to be serviceable, and replacing them before failure is critical to the long-term health of your transmission.

1. Clutch Plates

Function:

Clutch plates are responsible for engaging and disengaging the forward and reverse gears by applying hydraulic pressure. Each clutch pack consists of alternating friction and steel plates.

Wear Symptoms:

- Slipping under load

- Delay when shifting into gear

- Burnt oil smell

- Overheating

Typical Wear Points:

- Friction material wears thin or becomes glazed

- Steel plates warp or develop scoring

- Inner and outer splines become loose or damaged

Replacement Recommendation:

Inspect every 1,000 hours or annually. Replace whenever signs of slippage, overheating, or visible wear are present.

2. Bearings

Function:

Bearings support the input shaft, output shaft, and intermediate gear assemblies under constant load.

Wear Symptoms:

- High-pitched whining or humming

- Vibration under load

- Radial or axial shaft play

Typical Wear Points:

- Inner and outer races develop brinelling

- Roller elements become pitted or discolored

- Bearing cages crack

Replacement Recommendation:

Replace during major overhauls (every 2,000–3,000 hours) or immediately if noise or movement is detected.

3. Oil Seals and Gaskets

Function:

Oil seals keep transmission fluid inside while preventing contamination from entering. Gaskets maintain a tight seal between housing components.

Wear Symptoms:

- Visible oil leaks at input/output shaft

- Seepage around covers or case joints

- Drops in oil level between inspections

Typical Wear Points:

- Shaft sealing lips become hardened or cracked

- Gaskets degrade from heat and pressure

- Seal spring tension weakens

Replacement Recommendation:

Replace every time the transmission is disassembled. Preventive replacement is recommended every 1,500 hours, even without visible leakage.

Recommended Replacement Intervals

While exact replacement times vary depending on vessel use, environment, and maintenance habits, the following intervals provide a strong guideline for MG521 longevity:

Component |

Recommended Interval |

Notes |

| Clutch Plates | 1,000–1,500 hours | Replace if slipping or overheating occurs |

| Input/Output Bearings | 2,000–3,000 hours | Inspect for noise or play |

| Seals and Gaskets | 1,000–1,500 hours or annually | Replace anytime transmission is opened |

| Oil Filter | Every 250 hours | Replace with oil change |

| Oil Cooler Lines | Every 1,500 hours | Inspect for cracking or bulging |

| Control Cables | 1,000 hours or when damaged | Look for stiffness, fraying, or stretch |

Always monitor real-time wear indicators like oil condition, engagement performance, and vibration to determine if earlier service is needed.

Interchangeable Parts and Aftermarket Options

Using high-quality aftermarket parts is a cost-effective way to maintain performance without compromising durability. Diesel Pro Power offers aftermarket components for the MG521 that meet or exceed OEM specifications. However, not all parts are created equal, and compatibility should always be verified before installation.

Interchangeable Components

These parts are commonly swapped with aftermarket versions with no reduction in performance:

- Clutch Plates: Aftermarket friction materials provide equal or better heat resistance.

- Bearings: Most units use standard metric/tapered roller bearings available from trusted industrial manufacturers.

- Seals and Gaskets: Premium Viton or nitrile rubber compounds offer superior lifespan.

- Filters: Equivalent to OEM spin-on or cartridge filters, often with higher filtration ratings.

- Mounting Hardware: High-strength Grade 8 bolts match OEM torque specs and durability.

Tip: Always match the part number or dimensions to ensure compatibility, especially for clutch discs and gearsets.

Diesel Pro Power Premium Rebuild Kits

For convenience, Diesel Pro Power offers complete MG521 rebuild kits containing every critical service component in one box. These kits are ideal for preventive maintenance or full overhauls and are engineered to simplify the process for marine technicians and fleet managers.

What’s Included in a Premium Kit:

- Forward and reverse clutch plates (friction and steel)

- Input and output shaft bearings

- Intermediate bearings and thrust washers

- Input and output shaft oil seals

- Gasket and O-ring set for entire gearbox

- Oil filter (spin-on or cartridge)

- Snap rings, shims, and wear spacers

- Detailed part identification guide

Why Choose Diesel Pro Power Kits:

- Components are manufactured to precise tolerances and proven under marine conditions.

- Kits are compatible with all MG521 configurations and submodels.

- Eliminates the need to source individual parts.

- Reduces risk of using mismatched components.

- Backed by Diesel Pro’s OEM-matching warranty.

Ordering Tip: When placing an order, have your transmission serial number ready for verification. Diesel Pro Power customer service can help match the correct rebuild kit based on year, model, and configuration.

Importance of Using Proper Gasket and Seal Kits

One of the most common causes of leaks and transmission failure in the MG521 is improper gasket sealing. Many DIY rebuilds fail because of reusing old gaskets or using inferior aftermarket materials.

Why Gasket Quality Matters:

- Poor gasket seal leads to internal and external leaks.

- Incorrect material may degrade in hot marine environments.

- Improper thickness affects preload on shafts and bearings.

- Low-grade sealants can clog oil passages or break loose inside the case.

What to Look for in a Gasket/Seal Kit:

- Nitrile, Viton, or marine-rated rubber seals

- Pre-cut, model-specific gaskets with correct bolt-hole alignment

- Double-lip seals for added protection on input/output shafts

- Matching O-rings for cooler ports, valve body covers, and filter housing

Diesel Pro Power kits are guaranteed to contain all correct seals and gaskets specifically for the MG521 model — no trimming or guessing required.

Seal Installation Tips:

- Lightly coat seals with clean oil before installation.

- Use seal drivers or sockets that match the outer diameter.

- Never hammer directly on the seal.

- Ensure all mating surfaces are clean, dry, and free from gouges.

- Apply anaerobic or RTV sealant only where specified.

Torque Specs for Major Component Reinstallation

Proper torque is not optional. Under-torquing leads to vibration and loosening. Over-torquing risks distortion or stripping of threads. Use a calibrated torque wrench and apply specs exactly as outlined.

Torque Specification Chart for MG521

Component |

Torque Value (lb-ft) |

| Bell housing mounting bolts | 75–85 |

| Output flange bolts | 90–100 |

| Bearing carrier bolts | 35–50 |

| Snap ring retainers | 20–30 |

| Filter housing bolts | 25–35 |

| Servo cover bolts (EC300) | 18–22 |

| Shaft nut (with tab washer) | 200–220 |

| Control linkage clevis bolt | 12–15 |

Torque Tips:

- Always torque in a crisscross or star pattern to avoid warping.

- Replace bolts that show signs of stretching or corrosion.

- Apply anti-seize or thread locker where indicated.

- Verify torque after 25 hours of operation post-rebuild.

Final Tips for Reassembly and Post-Replacement Testing

Once parts are replaced and the MG521 has been reassembled, follow these essential steps:

1. Lubricate All Bearings and Seals

- Use marine-grade assembly lube or clean transmission oil.

- Ensure every bearing, clutch plate, and gear is coated before startup.

2. Rotate Input Shaft By Hand

- Confirm smooth movement and absence of binding.

- Check for clutch drag or shaft wobble.

3. Fill With Correct Oil

- Use SAE 30 non-detergent oil unless otherwise specified.

- Fill to the “Full” mark and allow oil to settle before rechecking.

4. Prime the Hydraulic System

- Follow priming procedures as outlined in the startup guide.

- Crank the engine without fuel or ignition to build pressure.

5. Run Through Full Shift Cycle

- Engage forward, neutral, and reverse while monitoring pressure.

- Confirm no delay, noise, or vibration.

6. Inspect for Leaks

- After engine runs 10–15 minutes at idle, inspect all seals and flanges.

- Re-torque fasteners as needed.

Conclusion: Confidence Through Correct Parts and Rebuild Practices

Maintaining the Twin Disc MG521 isn’t just about turning wrenches — it’s about using the right parts, at the right time, installed with the right torque. From clutch plates to shaft seals, every component contributes to the reliability and performance of your marine transmission.

Diesel Pro Power is your trusted partner for:

- Rebuild Kits with premium aftermarket components

- Detailed technical support for identifying wear and matching parts

- Fast shipping so you get back on the water sooner

- Expert content, like this guide, to support DIY and professional technicians alike

Rebuilt Twin Disc MG521 Marine Transmissions

Plate Kit For Twin Disc MG521 Marine Transmission

Gasket Kits For Twin Disc MG521 Marine Transmission

Videos About Twin Disc Transmissions

6 Reasons Your Twin Disc Transmission Has Low Oil Pressure

7 Reasons Your Twin Disc Transmission Is Overheating

3 Reasons Your Clutch Plates in Your Twin Disc Transmission Are Making Excessive Noise

Bull Gear On A Twin Disc Transmission

Rebuilt Twin Disc Transmissions

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588