Daily and Periodic Maintenance Schedules for Detroit Diesel Series 60 Engines

Preventive maintenance ensures optimal performance, longevity, and reliability of Detroit Diesel Series 60 engines. Adherence to scheduled inspections and service routines is essential.

Parts Catalog for 11.1L Detroit Diesel 60 Series Marine Engine

Parts Catalog for 12.7L Detroit Diesel 60 Series Marine Engine

Parts Catalog for 14L Detroit Diesel 60 Series Marine Engine

Daily Maintenance Checklist:

- Lubricating Oil: Check levels and look for leaks.

- Fuel Tank: Inspect for sufficient fuel and any signs of contamination.

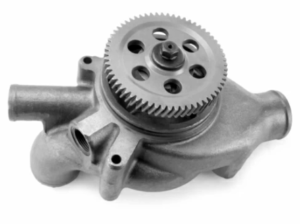

- Cooling System: Verify coolant levels and inspect hoses for leaks or damage.

- Turbocharger: Inspect for excessive noise, vibration, or visible leaks.

- Hoses and Belts: Check for wear, cracks, or improper tension.

Periodic Maintenance Intervals:

- 7,500 Miles (12,000 km): Inspect batteries, drive belts, and air compressors.

- 15,000 Miles (24,000 km): Replace lubricating oil, fuel filters, and coolant filters.

- 30,000 Miles (48,000 km): Inspect the radiator, air-to-air charge cooler, and exhaust system.

- 135,000 Miles (217,000 km): Comprehensive service, including engine steam cleaning and alternator inspection.

For heavy-duty applications like city transit, specific schedules are tailored to accommodate intense usage patterns, including replacing coalescing fuel filters and spark plugs at predefined intervals.

Inspections for Lubrication, Cooling, and Fuel Systems in Detroit Diesel Series 60 Engines

Lubrication System:

- Inspect oil levels daily.

- Look for signs of contamination, such as milky oil or metal shavings.

- Ensure oil pressure is within specified parameters.

Cooling System:

- Check coolant levels and ensure the presence of inhibitors.

- Inspect hoses and seals for leaks or degradation.

- Test pressure caps to confirm they maintain system pressure.

Fuel System:

- Inspect filters for clogs or water contamination.

- Check flexible fuel lines for wear and leaks.

- Ensure fuel pump pressure meets specifications.

Recordkeeping for Wear and Repairs in Detroit Diesel Series 60 Engines

Accurate recordkeeping is essential for monitoring engine performance and scheduling maintenance. Key practices include:

- Log Maintenance Activities: Include date, mileage, and type of service performed.

- Track Component Wear: Document belt tension, oil pressure, and coolant condition.

- Repair Histories: Record replaced parts and repair details for future reference.

Digital systems or logs can help streamline this process, ensuring timely preventive maintenance.

Troubleshooting Common Issues in Detroit Diesel Series 60 Engines

Common Problems:

- Low Oil Pressure:

- Cause: Worn bearings, clogged filters, or low oil levels.

- Solution: Replace worn parts and refill with appropriate oil grade.

- Overheating:

- Cause: Low coolant, faulty thermostats, or restricted airflow.

- Solution: Refill coolant, replace thermostats, or clean radiator fins.

- Fuel Starvation:

- Cause: Blocked fuel filters or faulty pumps.

- Solution: Replace filters and inspect fuel lines.

Noise, Vibration, and Leak Diagnoses for Detroit Diesel Series 60 Engines

Noise Issues:

- Investigate unusual engine noises, such as knocking or squealing. Causes may include loose belts, failing bearings, or improper injector timing.

Vibration Issues:

- Excessive vibration can indicate misaligned components, unbalanced driveshafts, or worn mounts.

Leak Detection:

- Check for oil, coolant, or fuel leaks. Use fluorescent dye or soapy water to identify difficult-to-see leaks.

Recommended Solutions and Guidelines for Detroit Diesel Series 60 Engines

- Use high-quality aftermarket parts from reputable suppliers like Diesel Pro Power.

- Replace components as per scheduled intervals to prevent unexpected failures.

- Perform diagnostics using recommended tools to ensure accurate fault detection.

By following these preventive maintenance strategies, Detroit Diesel Series 60 engines can operate efficiently, reducing downtime and extending service life.

Parts Catalog for 11.1L Detroit Diesel 60 Series Marine Engine

Parts Catalog for 12.7L Detroit Diesel 60 Series Marine Engine

Parts Catalog for 14L Detroit Diesel 60 Series Marine Engine

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588