The Cummins KTA19 is a powerhouse engine known for its durability and performance in demanding applications, from marine vessels to industrial equipment. However, even the most robust engines require consistent preventive maintenance to maximize lifespan, optimize performance, and minimize costly downtime. This guide outlines comprehensive maintenance strategies, including recommended service intervals, checklists, and best practices to ensure your KTA19 runs smoothly for years to come.

Parts Catalog for Cummins KTA19 Marine Engine

Recommended Service Intervals

Effective maintenance starts with understanding when to perform specific tasks. While service intervals can vary depending on usage conditions (e.g., marine vs. industrial environments), the following general guidelines provide a strong foundation. Always consult the Cummins service manual for model-specific recommendations.

1. Daily Maintenance (Pre-Start Checks)

Perform these checks before every operation to identify potential issues early:

- Check engine oil level and top up if needed.

- Inspect coolant level in the radiator and expansion tank.

- Look for visible leaks (oil, coolant, fuel).

- Check belts and hoses for signs of wear or cracking.

- Ensure the air filter indicator is in the green zone (if equipped).

- Inspect the exhaust system for loose connections or damage.

- Verify the fuel supply and check for water in the fuel separator.

2. Weekly Maintenance

Weekly checks help catch developing problems before they escalate:

- Inspect battery terminals for corrosion and ensure secure connections.

- Check alternator belt tension and condition.

- Clean or replace the air filter if dirty (depending on operating conditions).

- Drain water from the fuel-water separator.

- Verify engine mounts are secure.

- Inspect the turbocharger for oil leaks and unusual noises.

3. Monthly Maintenance

Monthly maintenance focuses on deeper system checks:

- Check coolant concentration with a refractometer to ensure proper freeze and boil protection.

- Inspect fuel lines and fittings for leaks or deterioration.

- Test emergency shutdown systems for proper function.

- Check crankcase breather for clogging or excessive oil buildup.

- Perform a visual inspection of wiring harnesses for chafing or damage.

4. Quarterly or 250-Hour Maintenance

For engines running frequently, every 250 operating hours (or quarterly) is a key interval:

- Change engine oil and filter using Cummins-recommended lubricants.

- Replace the fuel filter(s) to maintain clean fuel delivery.

- Inspect and clean the turbocharger compressor wheel and housing.

- Check and adjust valve lash (if needed).

- Perform an oil analysis to monitor engine wear trends.

5. Semi-Annual or 500-Hour Maintenance

At 500-hour intervals or twice a year:

- Change the coolant filter (if equipped).

- Flush and replace the crankcase ventilation filter.

- Inspect and test the cooling system thermostat.

- Clean the radiator and aftercooler to prevent overheating.

- Inspect injector performance using diagnostic tools.

6. Annual or 1,000-Hour Maintenance

Annually (or after 1,000 operating hours), perform comprehensive checks:

- Flush and replace coolant to prevent corrosion and scale buildup.

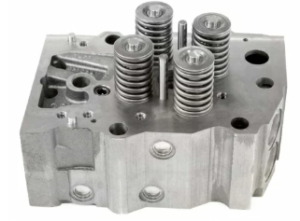

- Inspect cylinder head bolts for torque accuracy.

- Perform a compression test to evaluate engine health.

- Test the fuel injection system for proper spray patterns and pressure.

- Inspect engine mounts for signs of wear or deterioration.

7. Major Overhaul (10,000 to 15,000 Hours)

Depending on the engine’s operating conditions, a major overhaul may be required between 10,000–15,000 hours:

- Rebuild or replace key components like pistons, liners, bearings, and turbochargers.

- Complete fuel system overhaul (injectors, pumps).

- Replace or recondition the cylinder head.

- Inspect the crankshaft for wear or damage.

- Evaluate the camshaft and associated components.

Daily, Weekly, and Monthly Maintenance Checklists

Organized maintenance checklists help ensure no critical tasks are overlooked. Here’s a breakdown of what to include in your regular inspections.

✅ Daily Maintenance Checklist

- Oil Level: Check and top off as needed.

- Coolant Level: Inspect the radiator and reservoir.

- Leaks: Look for oil, coolant, and fuel leaks.

- Belts & Hoses: Check for cracks, fraying, or wear.

- Fuel Supply: Ensure adequate fuel and drain any water separators.

- Exhaust System: Inspect for leaks or damage.

- Air Filter Indicator: Ensure it’s in the safe zone.

- Warning Lights: Check for diagnostic alerts on the control panel.

✅ Weekly Maintenance Checklist

- Battery: Check charge, clean terminals, and ensure secure mounting.

- Turbocharger: Inspect for oil leaks and unusual sounds.

- Belt Tension: Adjust if necessary.

- Drain Water: From fuel-water separator.

- Mounts: Inspect engine mounts for looseness or cracking.

- General Cleanliness: Remove dirt and debris around the engine.

✅ Monthly Maintenance Checklist

- Coolant Quality: Test concentration with a refractometer.

- Fuel System: Inspect lines and fittings for leaks or cracks.

- Crankcase Breather: Clean or replace if clogged.

- Emergency Shutdown: Test for proper functionality.

- Wiring Harnesses: Inspect for signs of wear, chafing, or heat damage.

Extending Engine Life Through Proper Care

The longevity of your Cummins KTA19 isn’t just about following service intervals—it’s about adopting best practices that protect the engine in day-to-day operations. Here are proven strategies for maximizing engine life:

1. Maintain Proper Operating Temperatures

- Avoid prolonged idling, which leads to carbon buildup and incomplete combustion.

- Ensure the cooling system is functioning correctly to prevent overheating.

- Use proper thermostats to maintain optimal engine temperature.

Thermostat for Cummins KTA19, KTA38, KTA50 and QSK19 engines.

2. Monitor Oil and Fluid Quality

- Perform regular oil analyses to detect early signs of contamination or internal wear.

- Use high-quality lubricants recommended by Cummins for your specific engine model.

- Replace all filters (oil, fuel, coolant) at the specified intervals to prevent debris from circulating through the system.

3. Protect the Fuel System

- Always use clean, high-quality diesel fuel to prevent injector fouling.

- Drain the fuel-water separator regularly, especially in humid environments where condensation can accumulate.

- Add fuel stabilizers if the engine will sit idle for extended periods.

4. Address Issues Promptly

- Don’t ignore unusual noises, vibrations, or warning lights. These are often early indicators of larger problems.

- Fix small leaks immediately to prevent bigger issues down the line.

- Track engine performance over time. A gradual decline can signal the need for preventive action before a major failure occurs.

5. Keep the Engine Clean

- Dirt and debris can cause corrosion, overheating, and damage to sensitive components.

- Pressure wash the engine periodically (avoiding electrical components) to prevent buildup of grime and oil residues.

- Apply anti-corrosion sprays to exposed metal parts, especially in marine environments.

6. High Quality Parts & Fluids

- Always use genuine Cummins parts or high-quality aftermarket components such as those from Diesel Pro Power Inc, that meet or exceed OEM specifications.

- The use of low-quality parts can lead to premature wear, poor performance, and voided warranties.

7. Document All Maintenance Activities

- Keep a detailed maintenance log with dates, services performed, parts replaced, and operating hours.

- Tracking maintenance history helps identify patterns, aids troubleshooting, and improves resale value.

Special Considerations Based on Operating Conditions

1. Marine Applications

Engines in marine environments are exposed to saltwater, humidity, and constant load conditions, requiring more frequent maintenance:

- Flush the cooling system with fresh water after each use in saltwater environments.

- Apply anti-corrosion sprays to metal components.

- Check for electrical corrosion due to salt exposure.

2. High-Dust or Off-Road Environments

For engines in mining, construction, or dusty regions:

- Clean or replace air filters more frequently to prevent dust ingestion.

- Inspect turbocharger blades for dust erosion.

- Use pre-filters to reduce dust load on the primary air filter.

3. Standby Power Applications

Standby generators may sit unused for long periods but must start instantly when needed:

- Perform monthly test runs to keep seals lubricated and prevent fuel degradation.

- Use fuel stabilizers to maintain fuel quality during extended storage.

- Check battery health regularly to ensure reliable starting.

Common Preventive Maintenance Mistakes to Avoid

- Neglecting Scheduled Maintenance: Delaying oil changes or inspections can lead to catastrophic failures.\n

- Overlooking Minor Leaks: Small coolant or oil leaks often lead to bigger problems if ignored.\n

- Improper Torque: Failing to torque bolts to spec during maintenance can cause component failures.\n

- Using Incompatible Fluids: Mixing coolants or using the wrong oil grade can damage engine components.\n

- Ignoring Warning Lights: Engine management systems alert you to issues early—don’t ignore them.\n

- Skipping Valve Adjustments: Incorrect valve lash can lead to poor performance and early wear.\n

- Not Priming Fuel Systems Properly: After filter changes, improper priming can cause hard starts or damage injectors.

Disclaimer

Preventive maintenance schedules should be tailored to engine usage conditions. Operating environments, load factors, and duty cycles significantly impact service requirements. Always refer to the official Cummins KTA19 service manual for detailed service intervals, recommended procedures, and torque specifications. When in doubt, consult with a Cummins-certified technician to ensure proper care of your engine.

Parts Catalog for Cummins KTA19 Marine Engine

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588