The Process Of Rebuilding A Cummins Engine

Rebuilding a Cummins engine can be a complex and time-consuming process, but it can also be a rewarding and cost-effective way to breathe new life into an aging engine. Whether you’re a seasoned mechanic or a DIY enthusiast, rebuilding a Cummins engine requires careful planning, attention to detail, and the right tools and equipment.

Step 1: Assessment and Disassembly

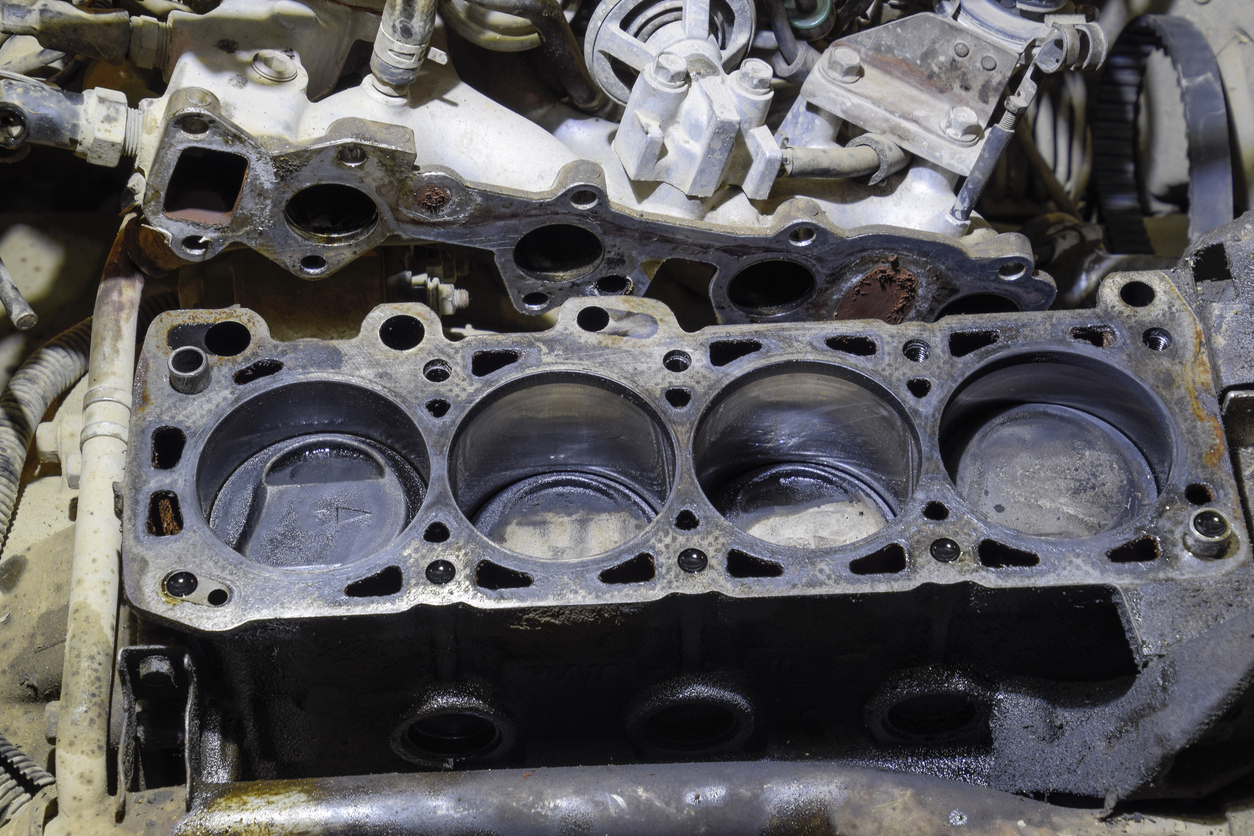

Before you begin the rebuilding process, it’s important to assess the condition of your Cummins engine and determine the scope of the work that needs to be done. This will involve a thorough inspection of the engine’s components, including the cylinder head, pistons, crankshaft, bearings, and connecting rods. If any of these parts are damaged or worn beyond repair, they will need to be replaced.

Once you have a clear understanding of the work that needs to be done, you can begin the disassembly process. This may involve removing the engine from the boat or vehicle, draining the fluids, and removing the cylinder head, pistons, and other components. It’s important to label and organize each component as you remove it to ensure that it can be reassembled correctly later on.

Step 2: Cleaning and Inspection

After disassembly, the engine components should be thoroughly cleaned and inspected for damage or wear. This may involve using a combination of chemical cleaners, wire brushes, and abrasive tools to remove dirt, rust, and corrosion. Once cleaned, each component should be carefully inspected for cracks, warping, or other signs of damage.

Step 3: Replacing and Rebuilding Components

If any components are found to be damaged or worn beyond repair, they will need to be replaced. This may involve ordering new parts. In addition to replacing damaged parts, it’s also a good idea to replace wear items like gaskets, seals, and bearings, even if they appear to be in good condition.

With all new components in hand, it’s time to begin rebuilding the engine. This will involve reassembling the components in the correct order, following the manufacturer’s specifications and torque values. The process will also involve measuring clearances and tolerances to ensure that each component is properly aligned and functioning as it should.

Step 4: Final Assembly and Testing

Once the engine has been fully rebuilt and all components are in place it’s time to start the engine. Before starting the engine, it’s important to check all fluid levels and perform a thorough inspection to ensure that everything is properly connected and tightened.

When it comes time to start the engine, it’s a good idea to do so in a controlled environment, such as a garage or shop. This will allow you to monitor the engine for any unusual noises, leaks, or other issues that may arise during the initial break-in period. Once you’re satisfied that the engine is running smoothly, it’s time to hit the water or the road and enjoy the fruits of your labor.

In conclusion, rebuilding a Cummins engine is not a task for the faint of heart, but it can be a satisfying and cost-effective way to restore an aging engine to like-new condition. By following these steps and paying attention to the details, you can ensure that your rebuilt Cummins engine will provide reliable and efficient performance for years to come.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588