Parts Catalog for Twin Disc MG5075A Marine Transmissions

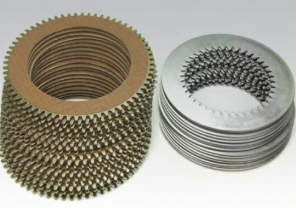

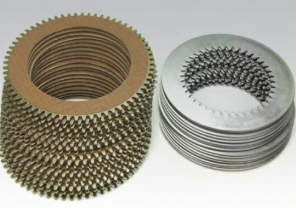

Plate Kit For Twin Disc MG5075A Marine Transmission

Gasket Kits For Twin Disc MG5075A Marine Transmission

Introduction to Routine Maintenance of the Twin Disc MG5075A Transmission

Routine maintenance is crucial to ensuring the Twin Disc MG5075A marine transmission operates at peak performance. Neglecting maintenance can lead to premature wear, costly repairs, and unexpected breakdowns, which can be particularly problematic in marine environments where downtime can be expensive and dangerous.

A proactive maintenance approach helps extend the lifespan of the transmission, optimizes fuel efficiency, and minimizes the risk of failures. This guide covers maintenance scheduling, fluid and filter changes, hydraulic system inspections, clutch adjustments, bearing and seal checks, and cooling system maintenance to ensure your Twin Disc MG5075A transmission remains in optimal working condition.

1. Maintenance Schedule for Optimal Performance

A structured maintenance schedule helps technicians and vessel operators keep track of essential servicing tasks. Below is a recommended routine maintenance schedule based on operating hours and conditions.

A. Daily Maintenance Checks

✔ Inspect for leaks around the transmission housing, hoses, and fittings.

✔ Check fluid levels using the dipstick; top off if needed.

✔ Monitor transmission temperature during operation.

✔ Observe for unusual noises or vibrations that indicate wear.

B. Weekly Maintenance Checks

✔ Check hydraulic system pressure to ensure proper clutch engagement.

✔ Inspect all mounting bolts for tightness.

✔ Verify cooling system function by checking oil temperature and flow rate.

C. Monthly Maintenance Checks

✔ Inspect transmission filters for contamination.

✔ Examine clutch operation for proper engagement and shifting performance.

✔ Check and clean external oil cooler to prevent overheating.

✔ Inspect transmission control cables for wear or misalignment.

D. Quarterly (Every 250 Hours) Maintenance Tasks

✔ Change transmission fluid and replace filters.

✔ Check for excessive bearing play or noise.

✔ Inspect seals and gaskets for signs of deterioration.

✔ Torque check all bolts to ensure no loosening due to vibration.

E. Annual (Every 1,000 Hours) Maintenance Tasks

✔ Perform a complete transmission inspection, including clutch packs.

✔ Disassemble and clean key components if necessary.

✔ Flush and replace hydraulic fluid to remove contaminants.

✔ Replace any worn seals, gaskets, and bearings.

Following this schedule minimizes downtime and maximizes the longevity of the Twin Disc MG5075A transmission.

2. Fluid and Filter Change Intervals

Transmission fluid serves as both a lubricant and a hydraulic medium in the MG5075A. Over time, the fluid can become contaminated with debris, moisture, and metal particles, reducing its effectiveness and causing damage to internal components.

A. Importance of Regular Fluid Changes

- Ensures smooth clutch engagement.

- Prevents overheating by maintaining proper cooling properties.

- Reduces wear on bearings, seals, and gears.

B. Recommended Transmission Fluid Types

✔ Use only Twin Disc-approved hydraulic transmission oil.

✔ Ensure the oil has high thermal stability and anti-wear properties.

✔ Select oil with proper viscosity for the operating environment.

C. Transmission Fluid Change Procedure

1. Draining Old Fluid

✔ Warm up the engine to operating temperature to help the oil drain easily.

✔ Shut down the engine and allow the transmission to cool.

✔ Locate the drain plug and place an oil collection pan beneath it.

✔ Remove the plug and allow all fluid to drain completely.

2. Replacing the Transmission Filter

✔ Remove the old filter and inspect for debris.

✔ Install a new filter, ensuring it is properly seated.

3. Refilling with New Transmission Fluid

✔ Pour the recommended amount of fresh fluid into the transmission filler port.

✔ Check the fluid level using the dipstick.

✔ Start the engine and cycle through gears to distribute oil evenly.

✔ Recheck fluid levels and top off if necessary.

Changing the transmission fluid every 250 hours prevents contamination and ensures smooth transmission performance.

3. Checking Hydraulic System Pressure and Leaks

The hydraulic system plays a vital role in gear engagement and shifting. Ensuring proper pressure levels and leak-free operation prevents clutch slipping and shifting issues.

A. Signs of Hydraulic System Issues

✔ Slow or delayed gear engagement.

✔ Inconsistent shifting or slipping clutches.

✔ Low hydraulic pressure readings on the gauge.

✔ Visible hydraulic fluid leaks around hoses and fittings.

B. Checking Hydraulic Pressure

- Locate the hydraulic pressure test port on the MG5075A transmission.

- Attach a hydraulic pressure gauge.

- Start the engine and shift into neutral.

- Observe pressure readings and compare them to manufacturer specifications.

C. Inspecting for Hydraulic Leaks

✔ Check hydraulic lines and fittings for leaks or cracks.

✔ Tighten any loose hose fittings to prevent leaks.

✔ Replace damaged hydraulic hoses immediately.

Proper hydraulic system maintenance ensures consistent and smooth shifting performance.

4. Inspecting and Adjusting Clutch Engagement

The MG5075A transmission uses hydraulically actuated clutch packs to engage gears. Improper clutch operation can lead to slipping, harsh shifting, or delayed engagement.

A. Symptoms of Clutch Issues

✔ Slipping under load (indicates worn clutch plates).

✔ Harsh or jerky engagement (caused by hydraulic pressure irregularities).

✔ Delayed shifting between forward and reverse.

B. Adjusting Clutch Engagement

- Ensure transmission fluid levels are correct.

- Verify hydraulic pressure is within recommended limits.

- If slipping occurs, inspect clutch friction plates for wear.

- Replace worn clutch packs as necessary.

Routine clutch inspections prevent transmission failures and ensure reliable operation.

5. Bearing and Seal Condition Checks

Bearings and seals prevent friction, overheating, and oil leaks within the MG5075A transmission. Regular inspection ensures these components remain in good condition.

A. Signs of Bearing or Seal Problems

✔ Excessive noise or grinding sounds.

✔ Oil leaks near the output or input shaft.

✔ Increased vibration during operation.

B. Checking Bearings

✔ Rotate the output shaft manually and feel for resistance.

✔ Use a stethoscope or vibration meter to detect irregular bearing noises.

✔ If worn, replace bearings to prevent catastrophic failures.

C. Inspecting and Replacing Seals

✔ Check shaft seals for wear or damage.

✔ If leaking, remove the seal and install a new OEM-approved seal.

Regular bearing and seal inspections prevent transmission damage and extend service life.

6. Cooling System Maintenance

The Twin Disc MG5075A transmission relies on an external oil cooler to regulate temperature and prevent overheating.

A. Signs of Cooling System Issues

✔ Transmission oil overheating under load.

✔ Reduced oil pressure due to thermal breakdown.

✔ Clogged or restricted oil cooler lines.

B. Cooling System Maintenance Steps

✔ Inspect oil coolers for debris or blockages.

✔ Flush cooler lines every 500 hours to remove contaminants.

✔ Check coolant flow rate and replace hoses if necessary.

A properly maintained cooling system ensures optimal operating temperatures and prevents transmission failure.

Conclusion

Routine maintenance is essential for ensuring the Twin Disc MG5075A transmission operates smoothly, efficiently, and reliably.

Key Takeaways:

✔ Follow a structured maintenance schedule based on engine hours.

✔ Regularly change transmission fluid and filters to prevent contamination.

✔ Monitor hydraulic system pressure to maintain shifting performance.

✔ Inspect clutch packs, bearings, and seals for wear.

✔ Maintain the cooling system to prevent overheating.

By adhering to these maintenance procedures, marine operators reduce downtime, optimize performance, and extend the lifespan of their MG5075A transmission.

Plate Kit For Twin Disc MG5075A Marine Transmission

Gasket Kits For Twin Disc MG5075A Marine Transmission

Videos About Twin Disc Transmissions

6 Reasons Your Twin Disc Transmission Has Low Oil Pressure

7 Reasons Your Twin Disc Transmission Is Overheating

3 Reasons Your Clutch Plates in Your Twin Disc Transmission Are Making Excessive Noise

Bull Gear On A Twin Disc Transmission

Rebuilt Twin Disc Transmissions

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588