The Caterpillar 3208 marine engine requires a thorough maintenance overhaul every 36,000 liters (9000 US gallons) of fuel consumption, 1000 service hours, or every two years, whichever comes first. This critical service interval includes comprehensive inspections, deep cleaning, component replacements, and system testing to ensure continued performance, reliability, and safety in demanding marine environments.

Cleaning and Testing the Aftercooler Core

Importance of Aftercooler Core Maintenance

The aftercooler core is vital for cooling compressed air before it enters the combustion chamber, enhancing engine efficiency and reducing emissions. Over time, it can accumulate debris, salt deposits, and oil, restricting airflow and heat transfer.

Step-by-Step Cleaning Procedure

- Engine Cool-Down: Allow the Caterpillar 3208 marine engine to cool completely before starting.

- Remove the Aftercooler Core: Disconnect air pipes and secure bolts; carefully extract the core.

- Inspect the Core: Look for corrosion, blockages, or physical damage.

- Flush Internally: Use a Caterpillar-recommended cleaning solution or a mild detergent in warm water. Backflush with low-pressure water to dislodge debris.

- Use Approved Cleaners: Caterpillar’s Hydrosolv solutions are recommended. Avoid caustic cleaners that can damage internal metals.

- Steam Clean: After chemical cleaning, use steam or hot water to remove residue and trapped debris.

- Dry Thoroughly: Use compressed air to remove water, directing airflow opposite to normal air path.

- Pressure Test the Core: Ensure no leaks; if present, repair or replace the core.

- Reinstall the Core: Follow OEM torque specifications.

Tips

- Clean more frequently in environments with high dust or salt exposure.

- Document cleaning intervals and findings.

Changing Coolant (DEAC)

Why Coolant Replacement is Crucial

Coolant degrades over time, losing its ability to regulate temperature and prevent corrosion. Dirty coolant can lead to overheating, gasket failure, and metal corrosion.

Steps for DEAC Change

- Allow the Engine to Cool: Never open a hot pressurized system.

- Drain Coolant: Open the drain valve or remove drain plugs. Collect coolant in an appropriate container.

- Flush the System: Use clean water and Caterpillar-recommended cooling system cleaner to remove residue and contaminants.

- Inspect Components: Check hoses, water pump, and thermostat for wear or leaks.

- Close Drains and Refill: Add Caterpillar DEAC (Diesel Engine Antifreeze Coolant) to system specifications.

- Bleed Air: Start the engine at low idle, gradually increase to operating temperature to purge trapped air.

- Check Levels and Leaks: Top off as needed and inspect for leaks.

Best Practices

- Use OEM-approved coolant and additive concentrations.

- Dispose of old coolant per environmental regulations.

Replacing Cooling System Water Temperature Regulator

Role of the Temperature Regulator

The water temperature regulator (thermostat) controls coolant flow to maintain optimal engine temperature. A faulty regulator can cause overheating or overcooling.

Replacement Steps

- Locate the Regulator: Usually at the coolant outlet housing.

- Drain Coolant Below Housing Level: Open the drain valve or remove the housing.

- Remove the Regulator: Take out the old unit, inspect for deposits or corrosion.

- Install New Regulator: Ensure proper orientation; use a new gasket or sealant as recommended.

- Reassemble Housing: Torque to manufacturer specifications.

- Refill Coolant and Test: Run the engine, check for proper temperature regulation and leaks.

Safety Tips

- Ensure the engine is cool before removal.

- Double-check torque specs to prevent leaks.

Thorough Engine Cleaning

Why a Clean Engine Matters

Accumulated grease and grime can hide leaks, increase fire hazards, and impede cooling. Regular engine cleaning improves inspection accuracy and heat dissipation.

Cleaning Procedure

- Cover Sensitive Components: Protect alternator, sensors, and electrical connectors with plastic.

- Apply Degreaser: Use an approved solvent or biodegradable cleaner.

- Brush Stubborn Areas: Loosen built-up grime with a soft brush.

- Rinse with Low-Pressure Water: Avoid high-pressure systems that may force water into sensitive parts.

- Inspect for Leaks or Damage: Once clean, check for hidden issues.

- Dry Thoroughly: Use compressed air or allow sufficient drying time.

Best Practices

- Schedule engine cleaning with other major services.

- Always use Caterpillar-approved or marine-safe cleaning agents.

Draining Governor Housing

Purpose

The governor housing regulates engine speed by controlling fuel delivery. Water condensation or contamination can accumulate inside, affecting performance.

Procedure

- Locate Drain Plugs: At the bottom rear of the governor housing.

- Remove Plugs: Allow water and sediment to drain completely.

- Inspect for Contaminants: If excessive debris is present, consult a technician.

- Reinstall Plugs: Ensure proper torque.

- Prime Fuel System: As required, using Caterpillar procedures.

Notes

- Drain more frequently in humid environments.

- Monitor for recurring water presence.

Cleaning or Inspecting Marine Transmission Oil Cooler

Importance

The marine transmission oil cooler removes excess heat from transmission fluid, preventing overheating and failure.

Procedure

- Isolate and Drain the System: Close valves and drain oil from the cooler.

- Remove the Cooler Core: Follow OEM steps.

- Clean Using Approved Solutions: Backflush with low-pressure water, avoiding damage.

- Inspect for Corrosion or Blockage: Replace the core if necessary.

- Reinstall and Test: Restore connections, refill oil, and test for leaks and performance.

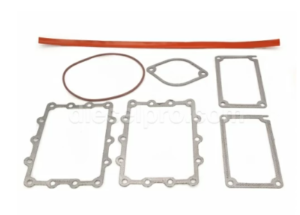

Tips

- Replace seals and gaskets during reassembly.

- Schedule cooler inspection with aftercooler cleaning.

Inspecting PCV Valve

Function

The Positive Crankcase Ventilation (PCV) valve prevents pressure buildup and recirculates blow-by gases, improving efficiency and reducing emissions.

Inspection Steps

- Locate the PCV Assembly: Typically at the crankcase breather.

- Disassemble and Inspect: Look for carbon buildup, diaphragm damage, and valve sticking.

- Clean or Replace Components: Use solvent or replace with new parts if needed.

- Reassemble and Test: Ensure a snug fit and proper operation.

Maintenance Tips

- Include PCV checks during valve lash or oil change intervals.

- Replace the diaphragm and seals during overhaul periods.

Summary

Servicing the Caterpillar 3208 marine engine every 36,000 L (9000 US gallons), 1000 service hours, or every two years is essential for long-term performance and reliability. Thorough inspections, cleaning, and part replacements keep the engine running smoothly and minimize the risk of costly failures.

Always follow Caterpillar’s official Operation & Maintenance Manual for specific procedures, torque settings, and fluid specifications.

Additional Resources

Practical Guide To Servicing The Caterpillar 3208 Marine Engine

Marine CAT 3208 Component Maintenance Life

Caterpillar 3208 Injectors: High-Quality Aftermarket Options from Diesel Pro Power

The History of the Caterpillar 3208 Engine

Common Applications of the Caterpillar 3208 Engine

Troubleshooting Common Issues with the Caterpillar 3208

Maintenance Tips for Maximizing the Life of Your Caterpillar 3208 Engine

Comparing the Caterpillar 3208 to Other Marine Engines

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588