Lubrication System

A well-maintained lubrication system ensures smooth operation, reduces wear, and prevents overheating of critical engine components. The Detroit Diesel Series 60 engine’s lubrication system includes the oil pump, pressure regulation valves, oil coolers, and filters. Proper maintenance and timely replacements are crucial for optimal performance.

Parts Catalog for 11.1L Detroit Diesel 60 Series Marine Engine

Parts Catalog for 12.7L Detroit Diesel 60 Series Marine Engine

Parts Catalog for 14L Detroit Diesel 60 Series Marine Engine

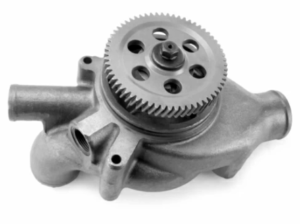

Oil Pump Mechanics

The oil pump is a gear-driven component that provides a steady flow of lubricating oil to all critical parts of the engine. Located at the engine’s lower front, it is directly driven by the crankshaft.

Key Features:

- Helical Gears: Minimize noise and wear.

- Relief Valve Integration: Prevents excess pressure build-up.

Maintenance Steps:

- Inspect the oil pump for wear or damage to gears and housing. Replace if wear exceeds tolerances.

- Test oil pressure at multiple RPMs to ensure the pump operates within specifications.

- Replace shims or adjust mounting as necessary to maintain proper gear lash (0.051–0.229 mm).

Pressure Relief and Regulation Valves

These valves maintain oil pressure within optimal ranges to ensure proper lubrication without causing component damage.

Relief Valve:

- Protects against excessive oil pressure by redirecting oil to the sump.

- Opens at approximately 105 psi (724 kPa).

Regulator Valve:

- Ensures stable pressure (around 45 psi or 310 kPa) to all critical engine parts.

Inspection and Maintenance:

- Remove the valves and inspect for scoring, sticking, or spring wear.

- Replace springs or valves if opening pressure deviates from specifications.

- Clean valve bodies and passages to remove any sludge or debris.

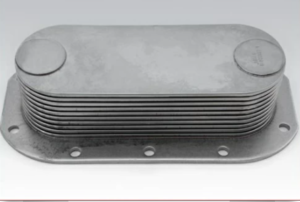

Oil Coolers and Filters

The oil cooler dissipates heat from the lubricating oil, ensuring it remains within optimal temperature ranges (104–114°C or 220–237°F). The filters remove contaminants that could harm the engine.

Oil Cooler Maintenance:

- Flush the oil cooler with an alkaline cleaning solution and rinse with hot water.

- Perform a pressure test at 75–100 psi to detect leaks. Replace the core if leaks are found.

Filter Replacement:

- Replace spin-on filters during every oil change or at recommended intervals (15,000 miles for on-highway applications).

- Pre-fill filters with clean engine oil before installation to prevent air pockets.

Fuel System

The Series 60 engine employs advanced fuel systems designed for efficiency and performance, including diesel fuel configurations and optional natural gas systems. Proper maintenance of these systems ensures optimal combustion, power output, and emissions compliance.

Diesel Fuel System Configuration

This system uses high-pressure injectors controlled by an electronic control module (ECM) for precise fuel delivery.

Components:

- Fuel pump

- Fuel injectors

- Fuel filters

Maintenance Tips:

- Inspect the fuel pump for wear and leaks. Replace seals or the entire unit if necessary.

- Test injectors for proper spray pattern and atomization. Replace any that are clogged or worn.

- Replace fuel filters at specified intervals to maintain clean fuel flow and prevent injector damage.

Natural Gas System Overview

The natural gas variant of the Series 60 engine includes components like gas injectors, a pressure regulator, and an electronic control module designed for compressed natural gas (CNG) or liquefied natural gas (LNG).

Maintenance Considerations:

- Regularly inspect gas lines and fittings for leaks.

- Clean or replace gas injectors if performance issues occur.

- Test pressure regulators for consistent output pressure and replace if fluctuating.

High-Pressure Fuel Injectors

Fuel injectors operate under high pressure (up to 30,000 psi) to deliver precise amounts of fuel directly into the combustion chamber.

Inspection and Servicing:

- Use specialized tools to remove and test injectors for leakage and spray patterns.

- Clean injectors using ultrasonic baths or replace them if clogging persists.

- Torque injector hold-down bolts to the specified value during reinstallation.

Cooling System

The cooling system of the Series 60 engine prevents overheating by regulating engine temperature through efficient coolant circulation. Proper maintenance of the radiator, water pump, and related components is essential to avoid costly repairs and downtime.

Radiator and Water Pump Details

Radiator:

The radiator dissipates heat from the coolant via airflow. Aluminum cores are common for their lightweight and efficient heat transfer.

Maintenance:

- Flush the radiator annually to remove sediment and scale.

- Inspect hoses and clamps for leaks or wear. Replace as necessary.

Water Pump:

The water pump circulates coolant throughout the engine and radiator. It is typically gear-driven or belt-driven.

Maintenance:

- Check for leaks at the weep hole, indicating seal failure.

- Inspect the impeller for damage or corrosion. Replace the pump if worn.

Coolant Flow Optimization

Proper coolant flow is vital for even heat distribution across the engine. Blockages or restrictions can lead to localized overheating and potential engine damage.

Steps to Optimize Coolant Flow:

- Use manufacturer-recommended coolant with the proper mix of water and antifreeze.

- Check for obstructions in coolant passages using a borescope.

- Verify thermostat functionality; replace it if it fails to open/close at the specified temperature.

Troubleshooting Overheating Issues

Overheating can lead to severe engine damage, including warped cylinder heads and seized pistons. Common causes include coolant loss, blockages, or pump failure.

Diagnosis and Resolution:

- Symptom: Rapid coolant temperature rise.

Cause: Low coolant levels or air pockets.

Fix: Refill coolant and bleed the system of air.

- Symptom: Intermittent overheating.

Cause: Malfunctioning thermostat or partially blocked radiator.

Fix: Replace the thermostat and flush the radiator.

- Symptom: Persistent overheating.

Cause: Faulty water pump or head gasket failure.

Fix: Replace the water pump or repair the head gasket.

By adhering to these maintenance procedures for the lubrication, fuel, and cooling systems, technicians can ensure the Detroit Diesel Series 60 engine operates efficiently and reliably for its intended lifespan.

Parts Catalog for 11.1L Detroit Diesel 60 Series Marine Engine

Parts Catalog for 12.7L Detroit Diesel 60 Series Marine Engine

Parts Catalog for 14L Detroit Diesel 60 Series Marine Engine

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588