February 11, 2025

Turbocharger Inspection and Maintenance

Routine Turbocharger Inspection

Visual Inspection:

Check Shaft Play:

Inspect Compressor and Turbine Blades:

Examine Oil Supply Lines:

Maintenance Tips:

Recognizing Signs of Turbocharger Failure

Loss of Power:

Excessive Exhaust Smoke:

Unusual Noises:

Oil Leaks:

Increased Oil Consumption:

Cleaning and Servicing the Turbocharger

Tools You’ll Need:

Steps to Clean the Turbocharger:

Proper Reinstallation Techniques

Reinstallation Steps:

Air Filtration and Manifold Servicing

Air Filtration System Components:

Ensuring Proper Airflow to the Engine

Troubleshooting Common Air Intake Issues

1. Restricted Airflow:

2. Air Leaks:

3. Turbo Lag:

Exhaust System Overview

Diagnosing Exhaust Leaks and Emission Control Issues

Common Symptoms of Exhaust Leaks:

Emission Control Issues:

Servicing the Exhaust Manifold

1. Inspection:

2. Removing the Manifold:

3. Cleaning and Repair:

4. Reinstallation:

Maintenance Best Practices

Disclaimer

Read More

February 11, 2025

Preparing for Disassembly

Required Tools and Safety Equipment

Precautions Before Starting

Draining Fluids and Disconnecting Components

1. Draining Engine Fluids:

2. Disconnecting External Components:

Step-by-Step Disassembly Process

1. Removing the Valve Cover and Rocker Arms

2. Removing the Cylinder Head

3. Extracting Pistons and Connecting Rods

4. Removing the Crankshaft

5. Handling Fuel System Components Safely

Inspecting Major Engine Components for Wear

1. Cylinder Head:

2. Pistons and Rings:

3. Crankshaft and Bearings:

4. Engine Block:

Reassembly Techniques

1. Cleaning and Preparation:

2. Installing the Crankshaft:

3. Installing Pistons and Connecting Rods:

4. Installing the Cylinder Head:

Proper Torque Specs and Bolt Tightening Sequences

Aligning Timing Marks Correctly

1. Setting the Crankshaft Timing:

2. Camshaft and Gear Alignment:

Tips for Ensuring Optimal Performance After Rebuild

Disclaimer

Read More

February 11, 2025

Overview of the Cummins KTA19 Engine for the Cummins KTA19

Applications: Marine, Industrial, and Power Generation for Cummins KTA19

Marine Applications for Cummins KTA19

1. Types of Marine Vessels Powered by the KTA19

2. Key Features for Marine Applications

3. Advantages in Marine Operations

Industrial Applications for Cummins KTA19

1. Industrial Equipment Powered by the KTA19

2. Key Features for Industrial Applications

3. Benefits in Industrial Operations

Power Generation Applications for Cummins KTA19

1. Types of Power Generation Applications

2. Key Features for Power Generation Applications

3. Advantages in Power Generation

What This Blog Series Covers for Cummins KTA19

Detailed Technical Specifications:

Maintenance and Service Guidelines:

Performance Optimization Tips:

Parts and Component Insights:

Real-World Applications and Case Studies:

Disclaimer

Read More

February 10, 2025

Introduction

This guide covers:

1. Deciding Between a Rebuild and Replacement

A. When to Choose an Overhaul (Rebuild)

B. When to Consider Engine Replacement

2. Key Steps in Overhauling a Cummins C Series Engine

A. Preparation

B. Engine Disassembly

C. Cleaning and Inspection

D. Reassembly with Diesel Pro Power Overhaul Kits

3. Post-Overhaul Testing and Inspection

A. Initial Testing

B. Break-In Procedure

C. Post-Overhaul Inspection

Conclusion

Read More

February 10, 2025

General Information for Cummins C Series Engines (6C, 6CT, 6CTA) (1991 and 1994 Certification Levels)

Question: What is the Cummins C Series engine used for?

Question: What are the common models in the Cummins C Series?

Question: What is the displacement of the Cummins C Series engine?

Question: What is the firing order for the Cummins C Series?

Question: What type of fuel does the Cummins C Series use?

Maintenance and Service for Cummins C Series Engines (6C, 6CT, 6CTA) (1991 and 1994 Certification Levels)

Question: How often should the oil be changed?

Question: What type of oil should be used?

Question: What is the oil capacity?

Question: What is the valve clearance specification?

Question: How often should valve adjustments be made?

Troubleshooting for Cummins C Series Engines (6C, 6CT, 6CTA) (1991 and 1994 Certification Levels)

Question: Why is my Cummins C Series engine overheating?

Question: What causes white smoke from the exhaust?

Question: Why is my engine hard to start in cold weather?

Question: What does low oil pressure indicate?

Question: What should I do if the engine won't start?

Specifications and Technical Data For Cummins C Series Engines (6C, 6CT. 6CTA)(1991 and 1994 Certification Levels)

Question: What is the compression ratio of the Cummins C Series?

Question: What is the normal operating oil pressure?

Question: What is the maximum allowable coolant temperature?

Question: What is the recommended battery size?

Question: What is the maximum turbocharger boost pressure?

Fuel System For Cummins C Series Engines (6C, 6CT. 6CTA)(1991 and 1994 Certification Levels)

Question: What type of fuel filter does the Cummins C Series use?

Question: How often should fuel filters be replaced?

Question: What is the fuel injection pressure?

Question: What is the fuel consumption rate?

Question: What causes fuel contamination issues?

Cooling System For Cummins C Series Engines (6C, 6CT. 6CTA)(1991 and 1994 Certification Levels)

Question: How do I bleed air from the cooling system?

Question: What is the coolant capacity?

Question: What coolant should be used?

Question: What causes coolant loss without visible leaks?

Question: How often should coolant be changed?

Lubrication System for Cummins C Series Engines (6C, 6CT, 6CTA) (1991 and 1994 Certification Levels)

Question: What is the oil filter part number for the C Series?

Question: How do I check the oil level?

Question: What causes oil dilution in diesel engines?

Question: How do I reset the oil change indicator?

Question: Can synthetic oil be used?

Electrical System for Cummins C Series Engines (6C, 6CT, 6CTA) (1991 and 1994 Certification Levels)

Question: What voltage does the Cummins C Series operate on?

Question: What size alternator is recommended?

Question: How do I troubleshoot charging system issues?

Question: What causes battery drain when the engine is off?

Question: How do I test the starter motor?

Exhaust and Emissions for Cummins C Series Engines (6C, 6CT, 6CTA) (1991 and 1994 Certification Levels)

Question: What is the EGR system?

Question: How do I know if my turbocharger is failing?

Question: What causes black smoke from the exhaust?

Question: How do I check for exhaust leaks?

Engine Testing and Diagnostics for Cummins C Series Engines (6C, 6CT, 6CTA) (1991 and 1994 Certification Levels)

Question: How do I perform a compression test?

Question: What is the normal compression pressure?

Question: How do I check timing on the C Series?

Question: What are signs of a blown head gasket?

Question: How do I diagnose poor engine performance?

Engine Assembly and Components for Cummins C Series Engines (6C, 6CT, 6CTA) (1991 and 1994 Certification Levels)

Question: What material is the Cummins C Series engine block made of?

Question: How many cylinders does the Cummins C Series have?

Question: What is the bore and stroke of the Cummins C Series engine?

Question: What is the purpose of the camshaft in the C Series engine?

Question: How is the camshaft driven in the C Series?

Turbocharger System for Cummins C Series Engines (6C, 6CT, 6CTA) (1991 and 1994 Certification Levels)

Question: Does the Cummins C Series have a turbocharger?

Question: What are signs of turbocharger failure?

Question: How do I maintain the turbocharger?

Question: What causes turbo lag?

Question: Can I upgrade the turbo on my Cummins C Series?

Cooling System (Advanced) for Cummins C Series Engines (6C, 6CT, 6CTA) (1991 and 1994 Certification Levels)

Question: What causes overheating despite having enough coolant?

Question: What is cavitation in the cooling system?

Question: How do I prevent cavitation?

Question: How do I test the thermostat?

Question: Why is there oil in my coolant?

Fuel System (Advanced) for Cummins C Series Engines (6C, 6CT, 6CTA) (1991 and 1994 Certification Levels)

Question: How do I bleed air from the fuel system?

Question: What are the symptoms of a clogged fuel filter?

Question: How do I know if my fuel injectors are bad?

Question: What causes injector failure?

Question: Can I clean diesel fuel injectors?

Electrical System (Advanced) for Cummins C Series Engines (6C, 6CT, 6CTA) (1991 and 1994 Certification Levels)

Question: Why is my alternator not charging the battery?

Question: What is a parasitic draw?

Question: How do I test for parasitic draw?

Question: Why does my starter click but not turn the engine?

Question: How do I check for a bad ground connection?

Exhaust System (Advanced) for Cummins C Series Engines (6C, 6CT, 6CTA) (1991 and 1994 Certification Levels)

Question: What causes excessive exhaust backpressure?

Question: How do I measure exhaust backpressure?

Question: What are the dangers of excessive exhaust backpressure?

Question: What causes a noisy exhaust?

Crankshaft and Bearings for Cummins C Series Engines (6C, 6CT, 6CTA) (1991 and 1994 Certification Levels)

Question: What causes crankshaft wear?

Question: How do I check for crankshaft end play?

Question: What is the purpose of main bearings?

Question: What causes bearing failure?

Question: How do I identify a spun bearing?

Cylinder Head and Valves for Cummins C Series Engines (6C, 6CT, 6CTA) (1991 and 1994 Certification Levels)

Question: What are signs of a cracked cylinder head?

Question: How do I check valve seat wear?

Question: What is valve float?

Question: What causes bent valves?

Question: How do I adjust valve lash?

Gaskets and Seals for Cummins C Series Engines (6C, 6CT, 6CTA) (1991 and 1994 Certification Levels)

Question: What causes head gasket failure?

Question: How do I detect a blown head gasket?

Question: What is the purpose of O-rings in diesel engines?

Question: How do I prevent gasket leaks?

Question: Why do seals fail prematurely?

Engine Overhaul and Rebuild for Cummins C Series Engines (6C, 6CT, 6CTA) (1991 and 1994 Certification Levels)

Question: When is an engine rebuild necessary?

Question: What parts are typically replaced during an overhaul?

Question: How long does an engine overhaul take?

Question: What causes premature engine wear?

Question: How do I break in a rebuilt engine?

Read More

January 8, 2025

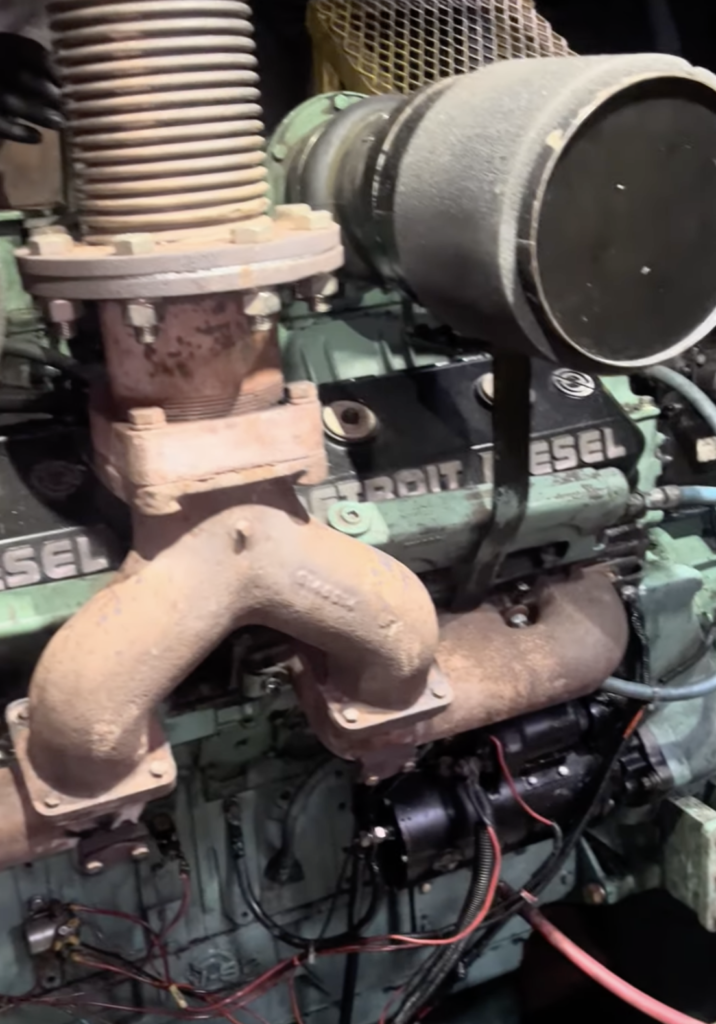

Introduction

Detroit Diesel 12V92 Configuration Comparison

Typical Marine Vessel Applications

Common Marine Transmission Pairings

Turbocharged Variants: Aftercooled and Intercooled Configurations

Aftermarket Support for Detroit Diesel 12V92 Marine Engines

Available Parts

Recommended Sources

Maintenance and Troubleshooting

Preventive Maintenance:

Common Issues:

Why Fleet Owners, Managers, and Mechanics Choose Diesel Pro Power for Detroit Diesel 12V92 Marine Engine Parts

Read More

Page 1 of 1012345...10...»Last »

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588