Cummins 6CTA 8.3 Marine Engine Torque Specs: A Comprehensive Guide

The Cummins 6CTA 8.3 engine is a trusted workhorse in various industries, including marine, agricultural, and industrial applications. Known for its reliability, efficiency, and durability, this engine is a popular choice among professionals who require high performance. However, maintaining its peak performance requires strict adherence to recommended torque specifications during assembly, repairs, and routine maintenance. This article provides a detailed overview of torque specs for key components of the Cummins 6CTA 8.3 engine, ensuring that you have all the information you need to keep your engine running smoothly.

Why Torque Specs Matter

Torque specifications are critical for achieving the correct clamping force in engine components. If bolts or capscrews are over-tightened, they can stretch beyond their elastic limit, leading to failure. Conversely, under-tightened bolts may loosen over time, causing leaks, misalignment, or catastrophic failure. By following the exact torque specs provided by Cummins, you can avoid these issues and ensure your engine operates efficiently and safely.

Torque Specs For The Cummins 6CTA 8.3 Marine Engine Cylinder Head

The cylinder head is one of the most important components of any engine, sealing the combustion chamber and maintaining compression. Proper torqueing of the cylinder head bolts is essential to prevent head gasket failure and maintain engine performance.

CYLINDER HEAD POST 1991 ( New Capscrews)

For engines manufactured after 1991 using new capscrews, follow this sequence:

- All 26 Capscrews: Torque to 95 N·m (70 ft-lb).

- 14 Long Capscrews: Torque to 145 N·m (107 ft-lb).

- 6 Short Capscrews (Exhaust Side): Torque to 105 N·m (77 ft-lb).

- 6 Short Capscrews (Intake Side): Torque to 95 N·m (70 ft-lb).

PART/MATERIAL/COLOR |

LENGTH |

TORQUE VALUE IN NM [ FT-LB ] |

| NEW CYLINDER HEAD CAPSCREWS (ALL 26 CAPSCREWS) | N/A | 95 N•M [ 70 FT-LB ] |

![NEW CYLINDER HEAD CAPSCREWS (ALL 26 CAPSCREWS) N/A 95 N•M [ 70 FT-LB ]](http://dieselpro.com/blog/content/uploads/2023/04/21-1024x474.png)

Cylinder Head& related components for Cummins 6CTA8.3 Marine Engine

PART/MATERIAL/COLOR |

LENGTH |

TORQUE VALUE IN NM [ FT-LB ] |

| NEW CYLINDER HEAD LONG CAPSCREWS ( 14 LONG CAPSCREWS) | N/A | 145 N•M [ 107 FT-LB ] |

![NEW CYLINDER HEAD LONG CAPSCREWS ( 14 LONG CAPSCREWS) N/A 145 N•M [ 107 FT-LB ]](http://dieselpro.com/blog/content/uploads/2023/04/17-1024x474.png)

Cylinder Head& related components for Cummins 6CTA8.3 Marine Engine

PART/MATERIAL/COLOR |

LENGTH |

TORQUE VALUE IN NM [ FT-LB ] |

| NEW CYLINDER HEAD SHORT CAPSCREWS (6 SHORT CAPSCREWS EXHAUST SIDE) | N/A | 105 N•M [ 77 FT-LB ] |

![NEW CYLINDER HEAD SHORT CAPSCREWS (6 SHORT CAPSCREWS EXHAUST SIDE) N/A 105 N•M [ 77 FT-LB ]](http://dieselpro.com/blog/content/uploads/2023/04/18-1024x474.png)

Cylinder Head& related components for Cummins 6CTA8.3 Marine Engine

PART/MATERIAL/COLOR |

LENGTH |

TORQUE VALUE IN NM [ FT-LB ] |

| NEW CYLINDER HEAD SHORT CAPSCREWS (6 SHORT CAPSCREWS INTAKE SIDE) | N/A | 95 N•M [ 70 FT-LB ] |

![NEW CYLINDER HEAD SHORT CAPSCREWS (6 SHORT CAPSCREWS INTAKE SIDE) N/A 95 N•M [ 70 FT-LB ]](http://dieselpro.com/blog/content/uploads/2023/04/19-1024x474.png)

Cylinder Head& related components for Cummins 6CTA8.3 Marine Engine

CYLINDER HEAD POST 1991 (Used Capscrews)

If you are reusing capscrews, the sequence changes slightly:

- All 26 Capscrews: Initial torque to 70 N·m (52 ft-lb).

- 14 Long Capscrews: Torque to 145 N·m (107 ft-lb).

- 12 Short Capscrews: Torque to 70 N·m (52 ft-lb). These are positioned on the exhaust and intake sides (positions 3, 4, 5, 6, 11, 12, 13, 14, 19, 20, 21, and 22).

PART/MATERIAL/COLOR |

LENGTH |

TORQUE VALUE IN NM [ FT-LB ] |

| USED CYLINDER HEAD CAPSCREWS (ALL 26 CAPSCREWS) | N/A | 70 N•M [ 52 FT-LB ] |

![USED CYLINDER HEAD CAPSCREWS (ALL 26 CAPSCREWS) N/A 70 N•M [ 52 FT-LB ]](http://dieselpro.com/blog/content/uploads/2023/04/21-1-1024x474.png)

Cylinder Head& related components for Cummins 6CTA8.3 Marine Engine

PART/MATERIAL/COLOR |

LENGTH |

TORQUE VALUE IN NM [ FT-LB ] |

| USED CYLINDER HEAD LONG CAPSCREWS ( 14 LONG CAPSCREWS) | N/A | 145 N•M [ 107 FT-LB ] |

![USED CYLINDER HEAD LONG CAPSCREWS ( 14 LONG CAPSCREWS) N/A 145 N•M [ 107 FT-LB ]](http://dieselpro.com/blog/content/uploads/2023/04/17-1-1024x474.png)

Cylinder Head& related components for Cummins 6CTA8.3 Marine Engine

PART/MATERIAL/COLOR |

LENGTH |

TORQUE VALUE IN NM [ FT-LB ] |

| USED CYLINDER HEAD SHORT CAPSCREWS (12 SHORT CAPSCREWS ON EXHAUST AND INTAKE SIDE, NUMBERS 3, 4, 5, 6, 11, 12, 13, 14, 19, 20, 21, & 22) | N/A | 70 N•M [ 52 FT-LB ] |

![USED CYLINDER HEAD SHORT CAPSCREWS (12 SHORT CAPSCREWS ON EXHAUST AND INTAKE SIDE, NUMBERS 3, 4, 5, 6, 11, 12, 13, 14, 19, 20, 21, & 22) N/A 70 N•M [ 52 FT-LB ]](http://dieselpro.com/blog/content/uploads/2023/04/20-1024x474.png)

Cylinder Head& related components for Cummins 6CTA8.3 Marine Engine

CYLINDER HEAD PRE 1991

For older engines built before 1991, use the following sequence:

- Torque all 26 capscrews to 40 N·m (30 ft-lb).

- Increase torque to 150 N·m (111 ft-lb).

- Perform a final torque of 220 N·m (162 ft-lb).

PART/MATERIAL/COLOR |

LENGTH |

TORQUE VALUE IN NM [ FT-LB ] |

| CYLINDER HEAD CAPSCREWS (ALL 26 CAPSCREWS) | N/A | 1. 40 N•M [ 30 FT-LB ] 2. 150 N•M [ 111 FT-LB ] 3. 220 N•M [ 162 FT-LB ] |

![CYLINDER HEAD CAPSCREWS (ALL 26 CAPSCREWS) N/A "1. 40 N•M [ 30 FT-LB ] 2. 150 N•M [ 111 FT-LB ] 3. 220 N•M [ 162 FT-LB ]"](http://dieselpro.com/blog/content/uploads/2023/04/21-2-1024x474.png)

Cylinder Head& related components for Cummins 6CTA8.3 Marine Engine

Torque Specs For The Cummins 6CTA8.3 Marine Engine Piston & Connecting Rod Assembly

The piston and connecting rod assembly is subjected to intense pressure and motion during engine operation. Ensuring that the connecting rod bolts and capscrews are torqued correctly is vital for the durability of these components.

Connecting Rod Nuts

- Torque to 30 N·m (22 ft-lb).

- Increase torque to 70 N·m (52 ft-lb).

- Perform an additional 60-degree turn.

Connecting Rod Capscrews

- Torque to 30 N·m (22 ft-lb).

- Increase torque to 70 N·m (52 ft-lb).

- Perform an additional 90-degree turn.

PART/MATERIAL/COLOR |

LENGTH |

TORQUE VALUE IN NM [ FT-LB ] |

| CONNECTING ROD NUTS | N/A | 1. 30 N•M [ 22 FT-LB ] 2. 70 N•M [ 52 FT-LB ] 3. 60 DEGREE TURN. |

![CONNECTING ROD NUTS N/A "1. 30 N•M [ 22 FT-LB ] 2. 70 N•M [ 52 FT-LB ] 3. 60 DEGREE TURN."](http://dieselpro.com/blog/content/uploads/2023/04/23-1024x643.png)

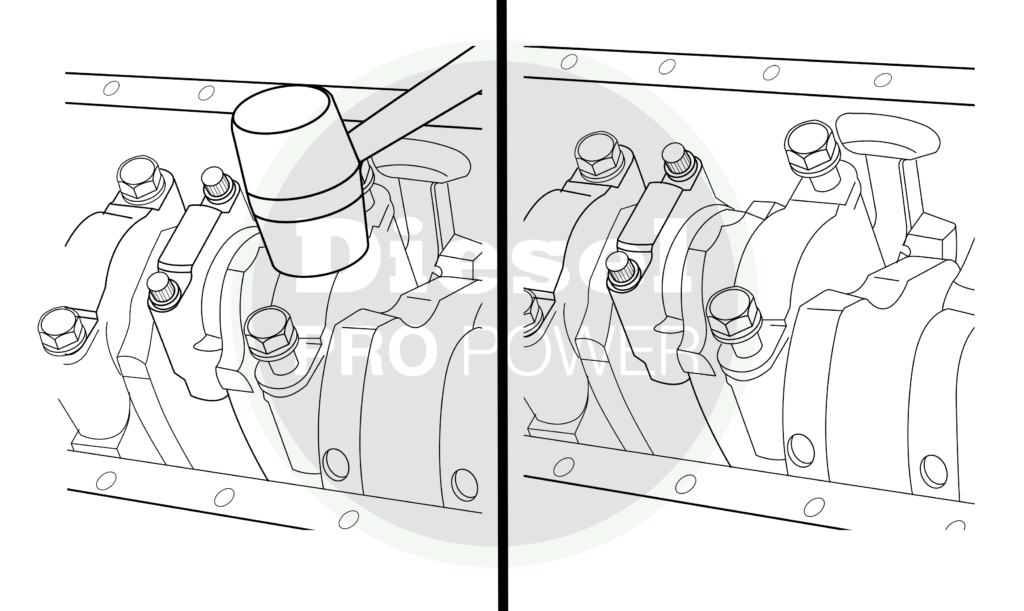

Connecting Rod & related components for Cummins 6CTA8.3 Marine Engine

PART/MATERIAL/COLOR |

LENGTH |

TORQUE VALUE IN NM [ FT-LB ] |

| CONNECTING ROD CAPSCREWS | N/A | 1. 30 N•M [ 22 FT-LB ] 2. 70 N•M [ 52 FT-LB ] 3. 90 DEGREE TURN. |

![CONNECTING ROD CAPSCREWS N/A "1. 30 N•M [ 22 FT-LB ] 2. 70 N•M [ 52 FT-LB ] 3. 90 DEGREE TURN."](http://dieselpro.com/blog/content/uploads/2023/03/12-1024x774.png)

Connecting Rod & related components for Cummins 6CTA8.3 Marine Engine

Torque Specs for Cummins 6CTA 8.3 Marine Engine Crankshaft

The crankshaft is the heart of the engine, converting linear motion into rotational power. Proper torque specs ensure that it operates smoothly without excessive vibration or wear.

- Crankshaft Capscrews (Initial Torque): Torque to 50 N·m (37 ft-lb).

- Final Torque for Capscrews: Increase to 190 N·m (140 ft-lb).

- Main Bearing Capscrews: Torque in stages:

- First stage: 40 N·m (30 ft-lb).

- Second stage: 150 N·m (111 ft-lb).

- Final stage: 270 N·m (199 ft-lb).

PART/MATERIAL/COLOR |

LENGTH |

TORQUE VALUE IN NM [ FT-LB ] |

| CRANKSHAFT CAPSCREWS (INITIAL TORQUE) | N/A | 50 N•M [ 37 FT-LB ] |

Crankshaft & related components for Cummins 6CTA8.3 Marine Engine

PART/MATERIAL/COLOR |

LENGTH |

TORQUE VALUE IN NM [ FT-LB ] |

| CRANKSHAFT CAPSCREWS (INITIAL TORQUE) | N/A | 1. 50 N.M [37 FT-LB] 2. 95 N.M [70 FT-LB] 3. 60° TURN. |

![CRANKSHAFT CAPSCREWS (INITIAL TORQUE) N/A "1. 50 N.M [37 FT-LB] 2. 95 N.M [70 FT-LB] 3. 60° TURN. "](http://dieselpro.com/blog/content/uploads/2023/04/22-1024x552.png)

Crankshaft & related components for Cummins 6CTA8.3 Marine Engine

Flywheel and Flywheel Housing

The flywheel and its housing play a critical role in engine operation by smoothing out power delivery and providing a connection point for the transmission.

Flywheel Bolts

- Torque to 120 N·m (89 ft-lb).

- Perform an additional 90-degree turn.

Flywheel Housing Bolts

- Torque to 55 N·m (41 ft-lb).

Rocker Arms and Valve Train

The valve train controls air and fuel flow in and out of the combustion chamber. Proper torqueing of the rocker arm bolts ensures that the valves open and close precisely as intended.

- Rocker Arm Bolts: Torque to 44 N·m (32 ft-lb).

- Valve Cover Bolts: Torque to 10 N·m (7 ft-lb).

Torque Specs for 6CTA 8.3 Marine Engine Injector and Fuel System

The fuel system is responsible for delivering precise amounts of fuel to the combustion chamber. Improper torqueing of injector bolts can lead to fuel leaks or improper spray patterns.

- Injector Hold-Down Bolts: Torque to 27 N·m (20 ft-lb).

- Fuel Line Nuts: Torque to 25 N·m (18 ft-lb).

Water Pump and Timing Components Torque Specs for 6CTA 8.3 Marine Engine

Cooling and timing systems are critical for engine longevity and performance. Torque specs for these components are equally important.

Water Pump Bolts

- Torque to 24 N·m (18 ft-lb).

Timing Gear Cover Bolts

- Torque to 22 N·m (16 ft-lb).

General Tips for Torqueing

- Use a Calibrated Torque Wrench: Always use a properly calibrated torque wrench to ensure accuracy.

- Follow the Tightening Sequence: For components like cylinder heads, always follow the recommended tightening sequence to avoid warping or uneven clamping force.

- Apply Proper Lubrication: Many bolts require lubrication to achieve the correct torque. Check the service manual for specific guidelines.

- Recheck After Warm-Up: For some components, it’s recommended to retorque after the engine has been warmed up and cooled down.

- Avoid Over-Tightening: Excessive torque can damage threads and lead to failure.

Common Mistakes to Avoid

- Skipping Steps in the Torque Sequence: Following the proper sequence is essential for uniform clamping.

- Not Replacing Damaged Bolts: Always inspect bolts and capscrews for signs of wear or damage before reuse.

- Using Incorrect Tools: A poor-quality torque wrench or the wrong socket size can lead to inaccurate torque application.

Frequently Asked Questions

1. What happens if I over-torque a bolt?

Over-torqueing can stretch the bolt beyond its elastic limit, weakening it and potentially causing it to snap or fail under load.

2. Can I reuse old bolts?

It depends on the condition of the bolts. Inspect them for wear, corrosion, or damage. For critical components like the cylinder head, it’s often recommended to replace bolts during reassembly.

3. How do I find the correct torque sequence?

The correct torque sequence is usually provided in the Cummins service manual. Following this sequence ensures even distribution of clamping force.

Conclusion

Adhering to the recommended torque specs for the Cummins 6CTA 8.3 engine is crucial for maintaining its performance, reliability, and longevity. From the cylinder head to the fuel system, every component has specific torque requirements that must be followed precisely. By using the guidelines outlined in this article, you can ensure that your engine remains in top condition and continues to deliver the performance you rely on.

For additional resources and support, consult the Diesel Pro blog or contact a Cummins-certified technician. Proper maintenance and attention to detail will keep your engine running smoothly for years to come.

Watch the video below to see On-site Diesel install a cylinder head on a Cummins 6CTA 8.3L :

Parts Catalog for Cummins 6CTA 8.3 Marine Engine

- Overhaul Kits for Cummins 6CTA 8.3 Marine Engine: Complete kits to refresh your engine, restoring power and efficiency and extending its lifespan.

- Fresh Water Pumps for Cummins 6CTA 8.3 Marine Engine: These pumps keep your engine cool by circulating fresh water through the cooling system, crucial for long hours of operation.

- Raw Water Pumps for Cummins 6CTA 8.3 Marine Engine: Essential for marine applications, these pumps draw seawater into the system to regulate engine temperature, preventing thermal damage.

- Cylinder Heads for Cummins 6CTA 8.3 Marine Engine: Engineered to handle high pressures, these cylinder heads support efficient combustion and reliable power output.

- Fuel Pumps for Cummins 6CTA 8.3 Marine Engine: Fuel pumps ensure optimal combustion by delivering fuel at the correct pressure, enhancing engine smoothness and fuel economy.

- Injectors for Cummins 6CTA Marine Engine: Precision-engineered injectors ensure fuel is delivered correctly to maximize power, efficiency, and reduce emissions.

- Oil Coolers & Oil Lubricating Pump for Cummins 8.3 6CTA Marine Engine: These components help maintain oil viscosity by cooling the oil and pumping it through the engine for lubrication.

- Turbos for Cummins 6CTA 8.3 Marine Engine: Designed to boost airflow into the combustion chamber, turbos enhance power and efficiency, ideal for heavy-duty applications.

- Crankshafts for Cummins 6CTA 8.3 Marine Engine: Our crankshafts convert engine power into rotational motion, ensuring reliable performance under demanding conditions.

- Camshafts for Cummins6CTA 8.3 Marine Engine: These control the engine’s valve timing, crucial for efficient combustion and maintaining optimal performance.

- Gaskets for Cummins 6CTA 8.3 Marine Engine : High-quality gaskets prevent leaks, maintain compression, and ensure overall engine efficiency and durability.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588