Parts Catalog for Twin Disc MG521 Marine Transmissions

Rebuilt Twin Disc MG521 Marine Transmissions

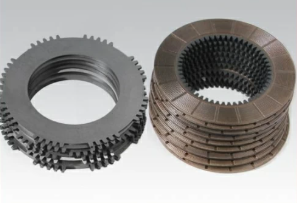

Plate Kit For Twin Disc MG521 Marine Transmission

Gasket Kits For Twin Disc MG521 Marine Transmission

The Twin Disc MG521 marine gear is engineered for long-lasting durability, precision engagement, and smooth power transmission. However, like all mechanical systems operating under high loads and in corrosive environments, issues may eventually arise. Whether you’re a marine technician, fleet manager, or vessel owner, this troubleshooting guide offers an in-depth walkthrough of the most common problems with the MG521 and how to resolve them before they lead to major failure or downtime.

Slipping or Delayed Engagement

Symptoms:

- The transmission does not respond immediately when shifting into forward or reverse.

- The vessel fails to move even though the engine RPM increases.

- Engagement occurs several seconds after the shift is made or slips under load.

Potential Causes:

- Low Hydraulic Oil Pressure

- Insufficient pressure can prevent the clutches from fully engaging.

- Possible sources include a weak pump, clogged filter, or low oil level.

- Contaminated or Incorrect Oil

- Using the wrong oil viscosity or type can impact clutch friction and hydraulic performance.

- Using the wrong oil viscosity or type can impact clutch friction and hydraulic performance.

- Worn Clutch Discs

- Friction material can wear out, especially if the transmission has been slipping for an extended period.

- Friction material can wear out, especially if the transmission has been slipping for an extended period.

- Faulty Shift Linkage or Control Cable

- If the cable does not move the control valve far enough, the clutch may not fully engage.

- If the cable does not move the control valve far enough, the clutch may not fully engage.

- Air in Hydraulic Lines

- Trapped air can compress under pressure, reducing effective clutch actuation.

- Trapped air can compress under pressure, reducing effective clutch actuation.

Solutions:

- Check and top off transmission oil. Use only SAE 30 non-detergent oil or approved hydraulic oil.

- Replace the oil filter if clogged or dirty.

- Purge hydraulic lines to remove air.

- Inspect clutch plates for glazing, thinning, or contamination and replace if needed.

- Adjust or replace control cables if there is excessive slack or misalignment.

Unusual Noises (Whine, Grind, Knock)

Symptoms:

- High-pitched whine at idle or under load.

- Grinding noise during shift transitions or acceleration.

- Intermittent knocking or clunking sounds while in gear.

Potential Causes:

- Worn Bearings or Gears

- Gear whine or bearing whirring typically stems from wear, misalignment, or lack of lubrication.

- Gear whine or bearing whirring typically stems from wear, misalignment, or lack of lubrication.

- Improper Gear Backlash

- Incorrect spacing between gear teeth leads to clunking or rhythmic knocking.

- Incorrect spacing between gear teeth leads to clunking or rhythmic knocking.

- Broken or Chipped Gear Teeth

- A chipped gear may grind against its counterpart, producing metal-on-metal noise.

- A chipped gear may grind against its counterpart, producing metal-on-metal noise.

- Loose Coupling or Mounting Bolts

- A loose output coupling may cause rotational slack and audible knocking.

- A loose output coupling may cause rotational slack and audible knocking.

- Excessive Prop Shaft Vibration

- Misalignment of the shaft can cause the noise to transmit through the gearbox.

- Misalignment of the shaft can cause the noise to transmit through the gearbox.

Solutions:

- Perform an inspection with a mechanic’s stethoscope to isolate the noise.

- Use a dial indicator to measure gear backlash and realign as necessary.

- Disassemble gear assembly and inspect for broken teeth or worn bearings.

- Torque all external fasteners to OEM specs.

- Check alignment of the engine and prop shaft.

High Operating Temperatures

Symptoms:

- Gearbox housing becomes extremely hot to the touch.

- Transmission oil temperatures exceed 200°F (93°C).

- Oil smells burnt or appears dark brown/black.

Potential Causes:

- Insufficient Oil Level

- Low oil reduces lubrication and increases friction.

- Low oil reduces lubrication and increases friction.

- Clogged or Failing Oil Cooler

- Heat exchange is restricted, allowing temperatures to rise quickly.

- Heat exchange is restricted, allowing temperatures to rise quickly.

- Slipping Clutches

- Partial engagement produces heat through friction.

- Partial engagement produces heat through friction.

- High Ambient Temperatures + Heavy Load

- May exceed the gearbox’s thermal capacity without additional cooling.

- May exceed the gearbox’s thermal capacity without additional cooling.

- Dirty or Low-Quality Oil

- Degraded oil loses its viscosity and heat-carrying capacity.

- Degraded oil loses its viscosity and heat-carrying capacity.

Solutions:

- Check oil level and top off using recommended lubricant.

- Flush and replace oil if discolored or contaminated.

- Inspect oil cooler lines and clean/replace cooler core if needed.

- Replace clogged filters that may restrict oil flow.

- Use infrared thermometer to identify hot spots and confirm cooler operation.

Oil Leaks (Input/Output Seal, Sump)

Symptoms:

- Visible oil under the gearbox or near flanges.

- Drips from the input shaft area or output coupling.

- Decreasing oil level over time without external explanation.

Potential Causes:

- Worn Shaft Seals

- Input and output seals degrade over time or may become cut by damaged shafts.

- Input and output seals degrade over time or may become cut by damaged shafts.

- Improper Flange Alignment

- Misalignment stresses the seal and causes leaks.

- Misalignment stresses the seal and causes leaks.

- Cracked Housing or Gasket Failure

- Impact, corrosion, or overtightening can compromise the case.

- Impact, corrosion, or overtightening can compromise the case.

- Overfilled Transmission

- Can cause oil to push past seals when heated.

- Can cause oil to push past seals when heated.

- Blocked Vent

- A plugged breather forces pressure to escape through seals.

- A plugged breather forces pressure to escape through seals.

Solutions:

- Clean and inspect leaking area to locate source.

- Replace damaged seals with OEM-quality or Diesel Pro Power aftermarket options.

- Check shaft surfaces for scoring and polish or replace if necessary.

- Ensure breather vents are clear and oil level is within correct range.

- Use proper seal installation tools and lubricate seal lips before insertion.

Low Oil Pressure

Symptoms:

- Oil pressure gauge reads below 200 PSI at idle.

- Sluggish or no response when shifting.

- Warning indicator triggered on EC300 systems.

Potential Causes:

- Oil Level Too Low

- Not enough fluid to supply the pump.

- Not enough fluid to supply the pump.

- Worn or Failing Pump

- Internal wear reduces pumping capacity.

- Internal wear reduces pumping capacity.

- Clogged Filter or Blocked Passage

- Restricts oil flow and starves clutch packs.

- Restricts oil flow and starves clutch packs.

- Bypassed Control Valve

- Defective valve allows oil to return without building pressure.

- Defective valve allows oil to return without building pressure.

- Internal Leakage from Seals or O-Rings

- Oil bypasses internally and doesn’t maintain pressure.

- Oil bypasses internally and doesn’t maintain pressure.

Solutions:

- Check and refill oil as needed.

- Replace filter and inspect for signs of metal or debris.

- Pressure-test pump using a calibrated gauge.

- Disassemble and inspect valve block for damage or stuck components.

- Replace worn seals in high-pressure sections.

Excessive Vibration

Symptoms:

- Noticeable shaking or rattling at idle or under load.

- Loud humming noise at certain RPMs.

- Couplings or mounts appear to move or deflect excessively.

Potential Causes:

- Engine-to-Gear Misalignment

- Uneven mounting surfaces, worn mounts, or hull deformation.

- Uneven mounting surfaces, worn mounts, or hull deformation.

- Propeller Shaft Imbalance

- Bent shaft or unbalanced prop transmits vibration upstream.

- Bent shaft or unbalanced prop transmits vibration upstream.

- Damaged Flexible Coupling

- Cracked or worn bushings transmit shock loads.

- Cracked or worn bushings transmit shock loads.

- Failed Engine or Gear Mounts

- Mounts no longer absorb vibration as designed.

- Mounts no longer absorb vibration as designed.

- Worn Bearings

- Allows radial or axial play during shaft rotation.

- Allows radial or axial play during shaft rotation.

Solutions:

- Use dial indicator to confirm alignment within ±0.003”.

- Replace flexible coupling if any cracks or offset are found.

- Inspect and replace engine/gear mounts as needed.

- Check shaft straightness and balance.

- Re-torque mounting bolts and isolate transmission with new shims if necessary.

Troubleshooting Charts and Flow Processes

The following flowcharts simplify the troubleshooting of the most common issues with the MG521:

1. Engagement Issues

Symptom: Slipping or delayed response

→ Check oil level

→ Inspect shift linkage for full travel

→ Measure oil pressure

→ Inspect clutch pack condition

→ Check for air in hydraulic lines

2. Overheating

Symptom: Gear housing feels hot, oil discolored

→ Confirm oil level

→ Inspect oil cooler flow

→ Check for slipping clutch

→ Replace oil and filter

→ Test pressure and recheck under load

3. Noisy Operation

Symptom: Grinding or whining

→ Use stethoscope to isolate sound

→ Check coupling and flange alignment

→ Inspect gear teeth for wear

→ Check bearing play

→ Replace damaged gears or bearings

4. Oil Leak

Symptom: Drips near shaft or housing

→ Clean area and trace origin

→ Inspect shaft seal condition

→ Confirm vent is clear

→ Replace seals and torque bolts evenly

→ Refill oil and recheck

5. Vibration

Symptom: Shaking under load

→ Confirm alignment at flanges

→ Check coupling and mounts

→ Inspect prop shaft

→ Verify bearing tolerances

→ Rebalance or realign

Emergency Bypass Procedures

In rare cases, you may encounter a situation that requires temporary operation or emergency shifting to maneuver a vessel back to port. While not a substitute for repair, these emergency measures can buy you time.

1. Manual Engagement

- Remove shift cable and manually move the control lever on the MG521 into forward or reverse.

- Do not operate at high RPMs—limit to idle speeds only.

- Watch for clutch overheating or vibration.

2. Overriding EC300 Controls

- Shut down and power-cycle EC300.

- If non-responsive, remove fuse and engage gear manually as above.

- Contact your controller manufacturer for reset instructions.

3. Cooling System Bypass

- If the oil cooler is leaking, loop hoses to bypass and reduce pressure.

- Limit operation to short durations and monitor temperature closely.

4. Limp Mode

- If excessive vibration or noise develops mid-transit, reduce RPM and keep shifts to a minimum.

- Use shortest route to safety and do not engage reverse if forward clutch is compromised.

Always document emergency procedures and prioritize full inspection and repair immediately after reaching safe harbor.

Conclusion: Confidence Through Diagnostic Clarity

The MG521 is a proven, rugged marine transmission—but even the best equipment needs a reliable diagnostic framework. Whether you’re troubleshooting poor engagement, chasing down a leak, or chasing out a vibration, this guide arms you with the knowledge to isolate and resolve the issue quickly.

Keep this checklist close, especially if you’re managing a fleet or working in remote conditions. And for every repair job, Diesel Pro Power has your back with:

- Premium aftermarket replacement parts

- Expert customer support

- Rebuild kits with bearings, gaskets, seals, and filters

- Shift cables and EC300-compatible controllers

Rebuilt Twin Disc MG521 Marine Transmissions

Plate Kit For Twin Disc MG521 Marine Transmission

Gasket Kits For Twin Disc MG521 Marine Transmission

Videos About Twin Disc Transmissions

6 Reasons Your Twin Disc Transmission Has Low Oil Pressure

7 Reasons Your Twin Disc Transmission Is Overheating

3 Reasons Your Clutch Plates in Your Twin Disc Transmission Are Making Excessive Noise

Bull Gear On A Twin Disc Transmission

Rebuilt Twin Disc Transmissions

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588