Parts Catalog for Twin Disc MG5075A Marine Transmissions

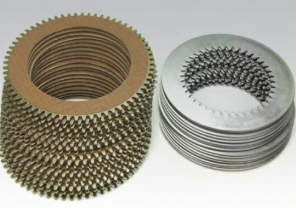

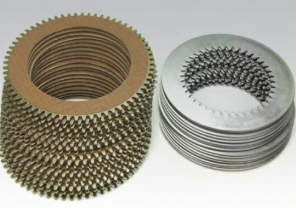

Plate Kit For Twin Disc MG5075A Marine Transmission

Gasket Kits For Twin Disc MG5075A Marine Transmission

Introduction to the Twin Disc MG5075A Transmission System

The Twin Disc MG5075A transmission is a high-performance marine gear system designed for various marine applications, including commercial workboats, fishing vessels, pleasure crafts, and military ships. Its primary function is to efficiently transfer power from the engine to the propeller while allowing precise control over speed and direction.

Understanding how the Twin Disc MG5075A transmission system operates, along with its core components, hydraulic system, lubrication requirements, and gear engagement principles, is essential for proper maintenance, troubleshooting, and optimization. This section provides a detailed breakdown of the MG5075A transmission system, helping marine technicians, engineers, and vessel operators to keep their propulsion systems in top working condition.

1. Transmission Components and Their Functions

The Twin Disc MG5075A transmission consists of multiple key components that work together to ensure efficient power transfer, precise shifting, and durability. Below is an in-depth look at the core components and their specific functions.

A. Input Shaft

- Receives power from the engine’s flywheel.

- Transmits rotational force to the internal gearing system.

- Designed for high torque capacity to handle marine engine loads.

B. Clutch Assembly (Hydraulically Actuated)

- Engages and disengages the forward and reverse gears.

- Uses hydraulic pressure to control engagement smoothly.

- Minimizes shock loading and reduces wear on components.

C. Reduction Gears

- Adjust the speed ratio between the engine RPM and propeller RPM.

- Provide multiple gear ratios to optimize power output.

- Help in reducing stress on the engine during high-load conditions.

D. Forward and Reverse Gear Sets

- Allow the vessel to change direction efficiently.

- Controlled by hydraulic clutch packs for smooth gear engagement.

- Made from hardened marine-grade steel for durability.

E. Hydraulic Pump

- Supplies pressurized oil to operate clutch packs and control shifting.

- Ensures smooth and reliable gear engagement.

- Prevents dry shifting, which can cause excessive wear.

F. Output Shaft

- Transfers final rotational power to the propeller shaft.

- Maintains alignment and torque transmission to the vessel’s drivetrain.

G. Bearings and Seals

- Support rotational components and reduce friction.

- Prevent oil leaks and fluid contamination.

- Require regular inspection and replacement when worn.

H. Cooling System Integration

- Works alongside external oil coolers to regulate transmission temperature.

- Prevents overheating and ensures fluid longevity.

- Essential for marine applications under high-load conditions.

Each of these components plays a vital role in the operation and efficiency of the MG5075A transmission. Regular maintenance and proper handling ensure longevity and peak performance.

2. Hydraulic System Overview

The Twin Disc MG5075A uses a hydraulic system to operate its clutch packs, providing smooth and reliable gear shifting. Unlike mechanical clutch systems, hydraulic operation ensures minimal wear and precise engagement, making it ideal for marine applications where consistent performance is critical.

A. Functions of the Hydraulic System

- Engages and disengages clutches without excessive wear.

- Provides instant response for forward and reverse shifting.

- Protects internal components from excessive shock loading.

B. Key Hydraulic System Components

1. Hydraulic Pump

- Pressurizes transmission fluid for clutch operation.

- Ensures a steady flow of hydraulic oil under all operating conditions.

- Requires periodic servicing to prevent failures.

2. Hydraulic Clutch Packs

- Engage forward and reverse gears using oil pressure.

- Provide smooth, slip-free transitions between gears.

- Must be inspected for wear and fluid contamination.

3. Control Valves

- Direct hydraulic fluid to the appropriate clutch pack.

- Ensure proper shifting operation and engagement timing.

- Require clean hydraulic oil to prevent clogging and malfunctions.

C. Hydraulic System Maintenance

- Regularly check hydraulic fluid levels to prevent starvation.

- Change hydraulic filters to prevent debris buildup.

- Inspect hoses and seals for leaks to maintain optimal performance.

- Ensure proper cooling to prevent fluid breakdown under high loads.

A well-maintained hydraulic system ensures smooth shifting, extended transmission life, and reduced wear on internal components.

3. Lubrication System and Cooling Requirements

The Twin Disc MG5075A transmission operates under heavy loads and high torque, requiring a high-performance lubrication and cooling system to prevent overheating and excessive wear.

A. Importance of Proper Lubrication

- Reduces friction between moving parts.

- Prevents metal-to-metal contact, which can lead to premature failure.

- Helps dissipate heat generated during operation.

B. Recommended Transmission Fluids

- Use high-quality marine-grade transmission oil.

- Ensure oil meets OEM specifications for viscosity and performance.

- Change fluid at manufacturer-recommended intervals to maintain performance.

C. External Cooling System

- The MG5075A transmission requires an external oil cooler.

- Helps dissipate heat and prevents fluid degradation.

- Must be free of blockages to ensure proper fluid flow.

D. Routine Maintenance for Lubrication and Cooling Systems

- Check oil levels before and after each trip.

- Flush and replace transmission fluid at scheduled intervals.

- Inspect oil coolers and heat exchangers for blockages.

- Monitor temperature gauges to prevent overheating.

By maintaining proper lubrication and cooling, operators can avoid costly repairs and maximize transmission lifespan.

4. Gear Engagement and Operation Principles

The Twin Disc MG5075A transmission allows for precise gear engagement, ensuring efficient vessel maneuverability. Understanding how the transmission engages gears is crucial for smooth operation and troubleshooting.

A. How Gear Engagement Works

- Operator selects gear (forward or reverse).

- Hydraulic pump pressurizes clutch pack.

- Clutch engages appropriate gear set.

- Power transfers from the input shaft to output shaft.

- Transmission shifts smoothly into gear.

B. Forward vs. Reverse Engagement

- Forward Gear Engagement: Uses primary clutch pack to rotate the output shaft in the desired direction.

- Reverse Gear Engagement: Uses secondary clutch pack, altering the gear set to change propeller rotation direction.

C. Common Gear Engagement Issues

- Slipping Clutch: Indicates worn friction plates or low hydraulic pressure.

- Delayed Engagement: Can be caused by contaminated fluid or air in hydraulic lines.

- Harsh Shifting: Often results from incorrect fluid viscosity or internal component wear.

D. Best Practices for Smooth Gear Engagement

- Always use the correct hydraulic fluid for smooth operation.

- Avoid rapid shifting between forward and reverse gears.

- Regularly inspect clutch packs for signs of wear.

- Ensure hydraulic pressures are within manufacturer specifications.

Understanding gear engagement principles helps technicians diagnose shifting problems and ensure smooth propulsion.

Conclusion

The Twin Disc MG5075A transmission is a critical component in marine propulsion systems, providing precise power control, efficient torque transfer, and smooth shifting.

Key Takeaways:

✔ The MG5075A is hydraulically actuated for smooth gear engagement.

✔ Proper lubrication and cooling prevent overheating and wear.

✔ Routine maintenance extends transmission lifespan and performance.

✔ Understanding gear engagement ensures smooth vessel operation.

By following best practices in maintenance, hydraulic system care, and fluid management, vessel operators can maximize the performance and longevity of their Twin Disc MG5075A transmission.

Plate Kit For Twin Disc MG5075A Marine Transmission

Gasket Kits For Twin Disc MG5075A Marine Transmission

Videos About Twin Disc Transmissions

6 Reasons Your Twin Disc Transmission Has Low Oil Pressure

7 Reasons Your Twin Disc Transmission Is Overheating

3 Reasons Your Clutch Plates in Your Twin Disc Transmission Are Making Excessive Noise

Bull Gear On A Twin Disc Transmission

Rebuilt Twin Disc Transmissions

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588