Weekly maintenance ensures that your Detroit Diesel 92 Series engine remains in optimal operating condition by addressing key systems such as lubrication, cooling, fuel, and electrical components. Regular weekly checks help identify potential issues early, reduce wear, and improve overall engine efficiency.

Parts Catalog for 6V92 Detroit Diesel Engines

Parts Catalog for 8V92 Detroit Diesel Engines

Parts Catalog for 12V92 Detroit Diesel Engines

Parts Catalog for 16V92 Detroit Diesel Engines

Lubrication System

Proper lubrication is essential to reduce friction, manage heat, and ensure long-term reliability of the engine.

-

Oil Levels and Quality

Detroit Diesel Oil Filler Cap for Head Cover 92 Series

- Inspection:

Dipstick (44.25″long) for Detroit Diesel 92 Series Engine

Detroit Diesel Dipstick (27 1/4″ length) for 92 Series

- Use the dipstick to verify oil levels are within the recommended range.

- Check the oil’s color and consistency for signs of contamination, such as fuel or coolant mixing.

- Actions:

Detroit Diesel Dipstick Tube for 92 Series

- Replenish oil with the correct grade if levels are low.

- Replace oil if contamination is detected to prevent internal engine damage.

- Inspection:

-

Oil Filter

Oil Filter for Detroit Diesel 12V92 Non- Turbo

Oil filter for Detroit Diesel engine – Cartridge type 12V92 Non- Turbo

Inspection:

- Examine the oil filter for clogs or visible signs of wear.

- Actions:

Oil Filter Removal Wrench for Detroit Diesel 92 Series

- Replace the oil filter if necessary to maintain proper flow and filtration.

Oil Filter & Related Components for 6V92 Non- Turbo Detroit Diesel Marine & Industrial Engines

Oil Filter & Related Components for 6V92 Turbo Detroit Diesel Marine & Industrial Engines

Oil Filter & Related Components for 8V92 Non- Turbo Detroit Diesel Marine & Industrial Engines

Oil Filter & Related Components for 8V92 Turbo Detroit Diesel Marine & Industrial Engines

Oil Filter & Related Components for 12V92 Non- Turbo Detroit Diesel Marine & Industrial Engines

Oil Filter & Related Components for 12V92 Turbo Detroit Diesel Marine & Industrial Engines

Oil Filter & Related Components for 16V92 Non- Turbo Detroit Diesel Marine & Industrial Engines

Oil Filter & Related Components for 16V92 Turbo Detroit Diesel Marine & Industrial Engines

- Replace the oil filter if necessary to maintain proper flow and filtration.

- Examine the oil filter for clogs or visible signs of wear.

-

Oil Pressure Monitoring

Detroit Diesel Engine Oil Pressure Gauge Detroit Diesel 92 Series Engines

- Standard Range:

- Confirm oil pressure remains between 30–60 psi under load conditions.

- Confirm oil pressure remains between 30–60 psi under load conditions.

- Troubleshooting:

- Low pressure may indicate a worn oil pump or leaks; high pressure could suggest blockages or a faulty pressure relief valve.

- Standard Range:

Oil Pump & Related Components for 6V92 Non- Turbo Detroit Diesel Marine & Industrial Engines

Oil Pump & Related Components for 6V92 Turbo Detroit Diesel Marine & Industrial Engines

Oil Pump & Related Components for 8V92 Non- Turbo Detroit Diesel Marine & Industrial Engines

Oil Pump & Related Components for 8V92 Turbo Detroit Diesel Marine & Industrial Engines

Oil Pump & Related Components for 12V92 Non- Turbo Detroit Diesel Marine & Industrial Engines

Oil Pump & Related Components for 12V92 Turbo Detroit Diesel Marine & Industrial Engines

Oil Pump & Related Components for 16V92 Non- Turbo Detroit Diesel Marine & Industrial Engines

Oil Pump & Related Components for 16V92 Turbo Detroit Diesel Marine & Industrial Engines

Coolant System

The coolant system regulates engine temperature and prevents overheating, especially in high-demand applications like marine or industrial use.

-

Coolant Levels

- Inspection:

- Check the coolant reservoir or radiator for proper levels.

- Check the coolant reservoir or radiator for proper levels.

- Actions:

- Replenish coolant with a 50/50 mixture of antifreeze and distilled water, or as specified for your operating conditions.

- Replenish coolant with a 50/50 mixture of antifreeze and distilled water, or as specified for your operating conditions.

- Inspection:

-

Water Pump, Hoses, and Radiator

- Inspection:

- Inspect the water pump for leaks or unusual noises, such as squealing, which may indicate bearing wear.

- Check hoses for cracks, bulges, or loose connections.

- Examine the radiator or heat exchanger for corrosion, blockages, or damaged fins.

- Actions:

- Replace worn hoses, tighten connections, and clean the radiator to ensure optimal flow and heat dissipation.

- Replace worn hoses, tighten connections, and clean the radiator to ensure optimal flow and heat dissipation.

- Inspection:

Raw water Pump & Related Components for 6V92 Non- Turbo Detroit Diesel Marine Engines

Raw water Pump & Related Components for 6V92 Turbo Detroit Diesel Marine Engines

Raw water Pump & Related Components for 8V92 Non- Turbo Detroit Diesel Marine Engines

Raw water Pump & Related Components for 8V92 Turbo Detroit Diesel Marine Engines

Raw water Pump & Related Components for 12V92 Non- Turbo Detroit Diesel Marine Engines

Raw water Pump & Related Components for 12V92 Turbo Detroit Diesel Marine Engines

Raw water Pump & Related Components for 16V92 Non- Turbo Detroit Diesel Marine Engines

Raw water Pump & Related Components for 16V92 Turbo Detroit Diesel Marine Engines

Fresh water Pump & Related Components for 6V92 Non- Turbo Detroit Diesel Marine & Industrial Engines

Fresh water Pump & Related Components for 6V92 Turbo Detroit Diesel Marine & Industrial Engines

Fresh water Pump & Related Components for 8V92 Non- Turbo Detroit Diesel Marine & Industrial Engines

Fresh water Pump & Related Components for 8V92 Turbo Detroit Diesel Marine & Industrial Engines

Fresh water Pump & Related Components for 12V92 Non- Turbo Detroit Diesel Marine & Industrial Engines

Fresh water Pump & Related Components for 12V92 Turbo Detroit Diesel Marine & Industrial Engines

Fresh water Pump & Related Components for 16V92 Non- Turbo Detroit Diesel Marine & Industrial Engines

Fresh water Pump & Related Components for 16V92 Turbo Detroit Diesel Marine & Industrial Engines

Fuel System

Maintaining the fuel system ensures efficient combustion, optimal performance, and protection against contamination.

-

Fuel Filters

Primary Fuel Filter For Detroit Diesel 92 Series Engines

- Inspection:

- Examine fuel filters for clogs or dirt accumulation.

- Examine fuel filters for clogs or dirt accumulation.

- Actions:

- Replace clogged filters to maintain consistent fuel flow and prevent injector damage.

Fuel Filter & Related Components for 6V92 Non- Turbo Detroit Diesel Marine & Industrial Engines

Fuel Filter & Related Components for 6V92 Turbo Detroit Diesel Marine & Industrial Engines

Fuel Filter & Related Components for 8V92 Non- Turbo Detroit Diesel Marine & Industrial Engines

Fuel Filter & Related Components for 8V92 Turbo Detroit Diesel Marine & Industrial Engines

Fuel Filter & Related Components for 12V92 Non- Turbo Detroit Diesel Marine & Industrial Engines

Fuel Filter& Related Components for 12V92 Turbo Detroit Diesel Marine & Industrial Engines

Fuel Filter & Related Components for 16V92 Non- Turbo Detroit Diesel Marine & Industrial Engines

Fuel Filter & Related Components for 16V92 Turbo Detroit Diesel Marine & Industrial Engines

- Replace clogged filters to maintain consistent fuel flow and prevent injector damage.

- Inspection:

-

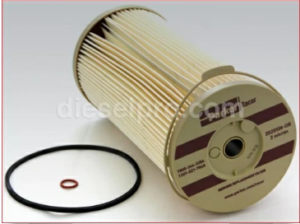

Fuel-Water Separator

1000 Racor Replacement fuel and water separator filter unit

900 Racor Replacement fuel and water separator

- Inspection:

- Check the separator for water or sediment buildup.

- Actions:

- Drain accumulated water or debris to prevent contamination of the fuel system.

- Inspection:

Battery and Electrical System

Reliable electrical components are essential for starting, charging, and powering auxiliary systems.

- Battery Terminals

- Inspection:

- Inspect terminals for corrosion, loose connections, or frayed cables.

- Inspect terminals for corrosion, loose connections, or frayed cables.

- Actions:

- Clean terminals with a wire brush and apply a thin coat of dielectric grease to prevent future corrosion.

- Secure all connections to ensure proper current flow.

- Inspection:

- Starting Motor

- Inspection:

- Test the starter motor for consistent engagement and cranking speed.

- Test the starter motor for consistent engagement and cranking speed.

- Troubleshooting:

- Slow cranking may indicate a weak battery, corroded connections, or a failing starter motor.

Starter & Related Components for 6V92 Non- Turbo Detroit Diesel Marine & Industrial Engines

Starter & Related Components for 6V92 Turbo Detroit Diesel Marine & Industrial Engines

Starter & Related Components for 8V92 Non- Turbo Detroit Diesel Marine & Industrial Engines

Starter & Related Components for 8V92 Turbo Detroit Diesel Marine & Industrial Engines

Starter & Related Components for 12V92 Non- Turbo Detroit Diesel Marine & Industrial Engines

Starter& Related Components for 12V92 Turbo Detroit Diesel Marine & Industrial Engines

Starter & Related Components for 16V92 Non- Turbo Detroit Diesel Marine & Industrial Engines

Starter & Related Components for 16V92 Turbo Detroit Diesel Marine & Industrial Engines

- Slow cranking may indicate a weak battery, corroded connections, or a failing starter motor.

- Inspection:

- Alternator

- Inspection:

- Test the alternator to confirm it maintains proper voltage output, typically 13.8–14.4 volts during operation.

- Test the alternator to confirm it maintains proper voltage output, typically 13.8–14.4 volts during operation.

- Actions:

- Replace a failing alternator to avoid insufficient battery charging and electrical system failures.

- Inspection:

Alternator & Related Components for 6V92 Non- Turbo Detroit Diesel Marine & Industrial Engines

Alternator & Related Components for 6V92 Turbo Detroit Diesel Marine & Industrial Engines

Alternator & Related Components for 8V92 Non- Turbo Detroit Diesel Marine & Industrial Engines

Alternator & Related Components for 8V92 Turbo Detroit Diesel Marine & Industrial Engines

Alternator & Related Components for 12V92 Non- Turbo Detroit Diesel Marine & Industrial Engines

Alternator & Related Components for 12V92 Turbo Detroit Diesel Marine & Industrial Engines

Alternator & Related Components for 16V92 Non- Turbo Detroit Diesel Marine & Industrial Engines

Alternator & Related Components for 16V92 Turbo Detroit Diesel Marine & Industrial Engines

Best Practices for Weekly Maintenance

- Use Quality Fluids and Components

- Ensure all replacement fluids and parts meet Detroit Diesel specifications or equivalent aftermarket standards.

- Ensure all replacement fluids and parts meet Detroit Diesel specifications or equivalent aftermarket standards.

- Record Observations

- Maintain a log of inspections, replacements, and adjustments for future reference and trend analysis.

- Maintain a log of inspections, replacements, and adjustments for future reference and trend analysis.

- Perform Checks During Downtime

- Schedule weekly maintenance during non-operational periods to avoid disrupting engine usage.

- Schedule weekly maintenance during non-operational periods to avoid disrupting engine usage.

- Address Issues Promptly

- Resolve any detected problems immediately to prevent minor issues from escalating into major failures.

Conclusion

Weekly maintenance for Detroit Diesel 92 Series engines ensures critical systems remain in peak condition and supports the long-term reliability of your engine. By focusing on the lubrication, coolant, fuel, and electrical systems, operators can identify potential problems early, minimize wear, and optimize performance. Regular, thorough maintenance is key to maximizing the efficiency and durability of these engines, reducing downtime, and avoiding costly repairs.

Parts Catalog for 6V92 Detroit Diesel Engines

Parts Catalog for 8V92 Detroit Diesel Engines

Parts Catalog for 12V92 Detroit Diesel Engines

Parts Catalog for 16V92 Detroit Diesel Engines

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588