Summary of Key Points

- Understanding Caterpillar Engines

- Maintenance History

- Parts Availability

- Performance and Fuel Efficiency

- Warranty and Documentation

- Compliance and Environmental Standards

- Total Cost of Ownership

- Vessel Condition

- Expert Evaluation

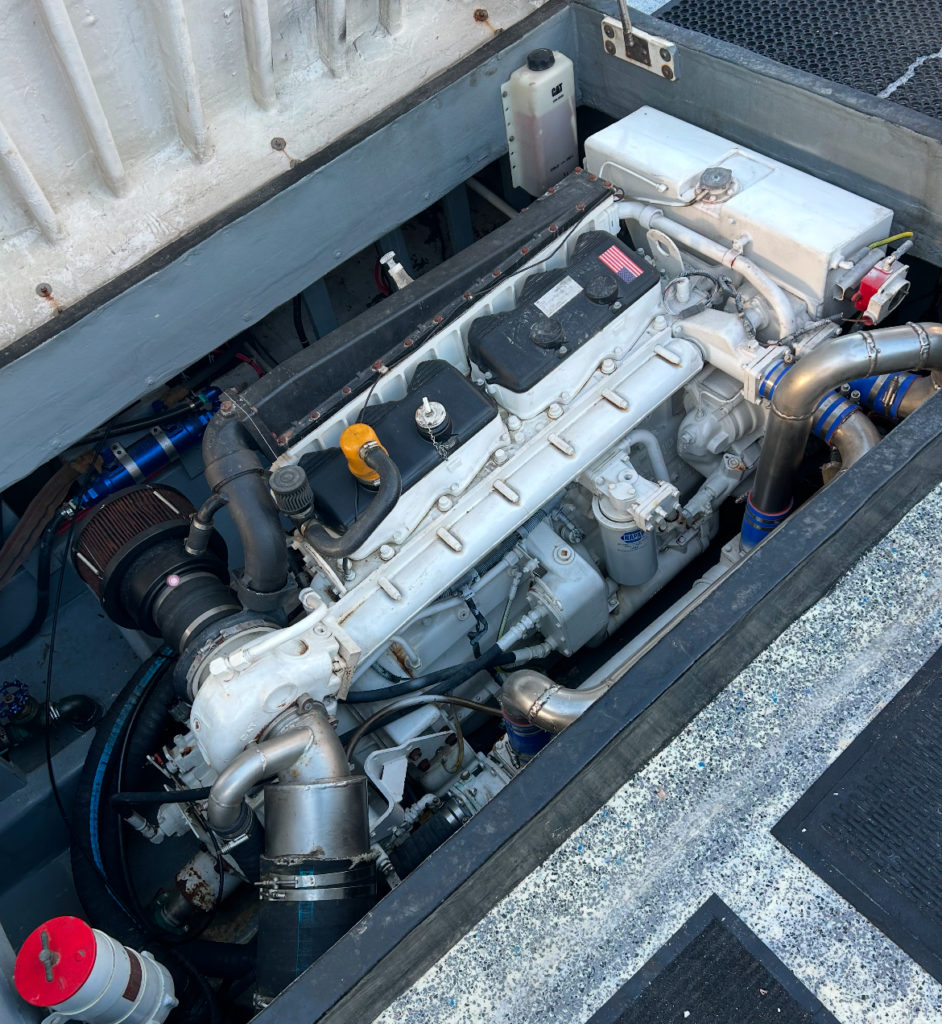

1. Understanding Caterpillar Marine Engines

Overview

- Caterpillar engines are designed for durability and heavy-duty use.

- Various engine models cater to different marine applications, including recreational, commercial, and industrial vessels.

- Knowledge of engine specifications ensures proper alignment with vessel requirements, enhancing performance and efficiency.

Engine Types

Caterpillar offers a wide range of marine engines, from high-speed to medium-speed models, catering to different vessel sizes and operational demands. High-speed engines, such as the 3400 series (e.g., 3406, 3408, and 3412), are widely used in recreational and light commercial vessels due to their power-to-weight efficiency. Medium-speed engines like the 3500 series (e.g., 3508, 3512, and 3516) are ideal for larger vessels requiring robust and sustained power.

For smaller applications, engines like the 3116, 3126, and 3208 are popular due to their compact size and reliability. Meanwhile, the 3304 and 3306 cater to medium-duty requirements with a balance of durability and fuel efficiency. Larger vessels, such as commercial fishing boats and tugboats, often rely on heavy-duty models like the D343 and D353, which are built to withstand intense workloads over long periods.

Key Features

Caterpillar engines are known for advanced engineering and innovative features that set them apart in the marine industry:

- Electronic Control Systems: Modern models like the C7, C9, C12, C13, C15, C18, and C32 feature advanced electronic control systems that optimize performance, monitor diagnostics, and improve fuel efficiency. These systems allow operators to fine-tune engines for specific operational needs.

- Fuel Efficiency: Many Caterpillar marine engines are designed with fuel economy in mind, making models such as the C12 and C18 suitable for long-range cruising or commercial operations.

- Robust Design: Models like the 3176 and 3196 are built with reinforced components, ensuring durability under challenging marine conditions.

- Versatility: Caterpillar engines are versatile, with configurations tailored for propulsion, auxiliary power, or both, depending on the vessel’s requirements.

Marine-Specific Models

Caterpillar offers a comprehensive range of marine engines designed to meet the unique challenges of marine environments. Below are some key models and their typical applications:

- 3116, 3126, and 3208: These lightweight engines are widely used in smaller recreational boats and commercial fishing vessels. They are valued for their reliability and ease of maintenance.

- 3176 and 3196: Designed for mid-sized vessels, these models offer higher horsepower while maintaining excellent fuel efficiency, making them suitable for ferries and patrol boats.

- 3304 and 3306: Known for their robustness, these engines are often used in tugboats and other workboats that demand consistent performance in tough conditions.

- 3406, 3408, and 3412: These versatile models serve a range of applications, from fishing trawlers to cargo vessels, offering a blend of power and reliability.

- 3508, 3512, and 3516: Built for heavy-duty applications, these engines are ideal for large commercial vessels like tankers and cruise ships, where sustained power is crucial.

- C7, C9, C12, C13, C15, C18, and C32: These modern engines are equipped with advanced electronic systems, making them highly efficient and suitable for both recreational and commercial marine applications. The C32, in particular, is known for its high horsepower, making it a favorite for luxury yachts and high-performance vessels.

- D343 and D353: These legacy models are still popular in industrial marine applications, offering unparalleled durability and reliability for older vessels that continue to operate globally.

By understanding these engine types, features, and specific models, buyers can ensure they select a Caterpillar engine that aligns with their vessel’s needs, ensuring long-term satisfaction and performance.

2. Maintenance History

Overview

- Proper documentation reveals the engine’s care and usage over its lifetime, offering insight into potential wear and tear.

- Regular maintenance ensures engine longevity, reliability, and optimal performance.

- Maintenance history directly impacts the resale value of the vessel, as well-maintained engines fetch higher prices in the market.

Scheduled Servicing

- Caterpillar engines require consistent servicing to perform at their peak. Key maintenance tasks include oil changes, filter replacements, and system inspections.

- Look for detailed records of routine servicing intervals. For Caterpillar engines, such as the 3116, 3208, or C18, oil changes are typically required every 250 to 500 hours, depending on operating conditions.

- Ensure that inspections for key components, like fuel injectors, cooling systems, and turbochargers, were conducted as recommended. Neglect in these areas can lead to costly repairs down the line.

- Servicing by certified Caterpillar technicians or a reputable marine diesel mechanic is a good indicator of quality care.

Repairs and Rebuilds

- Investigate the engine’s repair history, focusing on major repairs or component replacements. For instance, key components like turbochargers, cylinder heads, or water pumps for engines such as the 3406 or 3412 may indicate heavy use.

- Look for evidence of rebuilds, especially for engines with high operating hours. Rebuild kits for models like the 3406 or C32 can significantly extend engine life when installed correctly.

- Ensure that rebuilds adhered to proper standards using high-quality aftermarket kits or Caterpillar-specific rebuild kits with OEM-matching warranties.

- Review records for any recurring issues or improper repairs, as these can signal future reliability concerns.

Engine Hours

- Engine hours are a critical metric of usage and should be evaluated carefully. Caterpillar engines, like the 3508 or 3516, are built to handle thousands of hours under heavy-duty conditions, but maintenance becomes more frequent as hours accumulate.

- For recreational vessels, lower engine hours are generally preferable, as they indicate less wear and tear. However, for commercial vessels, high engine hours accompanied by a strong maintenance history can still indicate a reliable engine.

- Check for major service milestones, such as 10,000-hour or 20,000-hour overhauls. Engines like the C12 or C15typically require specific component inspections and replacements at these intervals.

- Verify engine hours against maintenance records to ensure that recommended service intervals were followed. Any discrepancies may indicate lapses in care.

By thoroughly reviewing the maintenance history of Caterpillar engines, buyers can gauge the engine’s current condition, identify potential future maintenance needs, and make an informed decision about their purchase. A well-documented maintenance history not only ensures engine reliability but also enhances the vessel’s resale value.

3. Parts Availability

Overview

- Aftermarket Options

- 3200 Series

- 3400 Series

- 3500 Series

- Raw Water Pump Support

- Supply Chains

- Long-Term Compatibility

Aftermarket Options

- Diesel Pro Power offers premium aftermarket parts that meet or exceed OEM quality, ensuring reliable performance for your Caterpillar marine engine.

- We provide comprehensive support for essential components, including raw water pumps, gaskets, seals, bearings, and rebuild kits.

- Our aftermarket parts are engineered to deliver long-lasting durability, whether you operate a 3208 in a recreational vessel or a 3516 in a commercial fleet.

- For the 3200, 3400, and 3500 series engines, we offer full aftermarket support, covering critical parts such as turbochargers, injectors, water pumps, and more.

3200 Series

- Aftermarket Parts for 3208: This engine is popular in recreational and light commercial vessels. Diesel Pro Power provides full aftermarket support, including raw water pumps, gasket kits, and fuel system components tailored for the 3208.

3400 Series

- Aftermarket Parts for 3406: Known for versatility in fishing boats and cargo vessels, we offer raw water pumps, rebuild kits, and turbochargers for the 3406.

- Aftermarket Parts for 3408: Supporting heavy-duty operations, Diesel Pro Power provides cylinder heads, seals, and marine cooling system components for the 3408.

- Aftermarket Parts for 3412: This powerhouse engine benefits from a wide range of parts, including injectors, bearings, and raw water pumps designed for durability.

3500 Series

- Aftermarket Parts for 3508: Designed for large commercial vessels, we offer camshafts, gaskets, and high-capacity raw water pumps for the 3508.

- Aftermarket Parts for 3512: For tugboats and ferries, Diesel Pro Power provides turbochargers, cooling system components, and gasket kits for the 3512.

- Aftermarket Parts for 3516: Supporting the most demanding marine applications, our inventory includes rebuild kits, bearings, and raw water pumps for the 3516.

Raw Water Pump Support

- Diesel Pro Power provides raw water pump support for nearly every Caterpillar marine engine model, from compact engines like the 3116 to larger models like the 3516.

- Raw water pumps are critical for cooling systems, especially in marine environments where saltwater and debris can cause wear. Our pumps are designed to withstand harsh conditions, ensuring reliability and longevity.

- Whether you need a replacement pump for a 3208 or a high-capacity pump for a 3508, we offer solutions tailored to your engine’s needs.

Supply Chains

- Reliable supply chains are essential, especially for vessels operating internationally. Diesel Pro Power ensures fast shipping and dependable support for Caterpillar engines worldwide.

- For global operators, having access to a trusted aftermarket supplier minimizes downtime, helping you avoid costly delays and keeping your vessel operational.

Long-Term Compatibility

- Ensuring the long-term availability of parts is critical, particularly for older engines such as the 3304, 3306, and 3406. These engines remain popular due to their durability, but parts availability can vary without a trusted supplier.

- Diesel Pro Power specializes in providing long-term support for both legacy and modern Caterpillar engines, ensuring your investment remains operational for years to come.

- For the 3200, 3400, and 3500 series, we stock a wide range of components to meet current and future maintenance needs, offering peace of mind for vessel operators.

With Diesel Pro Power’s extensive aftermarket support and raw water pump availability for nearly every marine Caterpillar engine, operators can rely on timely repairs and maintenance. Whether you’re managing a recreational vessel with a 3208 or a commercial fleet with 3516 engines, we ensure that your parts are always within reach to keep your operations running smoothly.

4. Performance and Fuel Efficiency

Overview

- Power Output

- Fuel Consumption

- Load Compatibility

Power Output

- The power output of a Caterpillar engine must match the demands of your vessel’s size and application. Selecting an undersized engine, like the 3116, for a larger vessel may result in poor performance, excessive strain, and shortened engine lifespan.

- Conversely, oversized engines, such as the 3516, installed in vessels that don’t require their full power capabilities may lead to wasted fuel and higher operational costs.

- Caterpillar offers a wide range of marine engines to suit different needs:

- Smaller Engines: The 3208 or 3406 are ideal for fishing boats, yachts, and smaller commercial vessels, balancing power and fuel efficiency.

- Mid-Range Engines: The 3412 or 3508 are suitable for mid-sized vessels like ferries or offshore support ships.

- High-Powered Engines: Larger models like the 3512 or 3516 deliver exceptional power for heavy-duty applications, such as tugboats or cargo ships.

Fuel Consumption

- Fuel consumption is a critical factor in operating costs, especially for vessels with long operating hours.

- Caterpillar engines, such as the C32, are designed to maximize fuel efficiency without sacrificing performance. This is particularly important for vessels that require consistent power over long distances.

- Check the manufacturer’s specifications for fuel consumption rates under different load conditions. For example:

- 3208: Known for its economical operation in smaller vessels.

- 3408: Offers a balance of power and fuel efficiency for mid-sized commercial applications.

- 3516: Though powerful, efficient operation depends on matching load requirements and performing regular maintenance.

- Regular servicing of key components, such as injectors, fuel pumps, and air filters, ensures fuel efficiency is maintained. Neglect in these areas can lead to increased consumption and operational costs.

Load Compatibility

- Engines perform best when operating within their designed load range. Overloading an engine like the 3406 can cause strain, overheating, and reduced lifespan.

- On the other hand, underloading a high-capacity engine like the 3512 can lead to incomplete combustion, carbon buildup, and decreased efficiency over time.

- Match your engine’s capacity to your vessel’s typical usage patterns:

- For Recreational Boats: The 3116 or 3208 provides reliable performance without excessive power, ensuring efficiency during cruising.

- For Commercial Vessels: The 3412 or 3512 handles consistent, heavy loads with ease, delivering steady performance in demanding environments.

- Operators should monitor engine load regularly, using onboard diagnostic tools or manual calculations, to ensure the engine is performing within its optimal range.

Optimizing Performance and Efficiency

- Conduct regular engine tune-ups to maintain peak performance. Cleaning aftercoolers, adjusting valves, and calibrating fuel injectors can significantly improve both power output and fuel efficiency.

- Use high-quality aftermarket parts, such as raw water pumps and gasket kits from Diesel Pro Power, to maintain the engine’s cooling and combustion efficiency.

- Consider operational factors such as speed and weather conditions, as running the engine at optimal RPMs can extend its life and reduce fuel usage.

By carefully evaluating Power Output, Fuel Consumption, and Load Compatibility, vessel operators can maximize the performance and fuel efficiency of their Caterpillar engines. Whether you’re managing a 3208 for recreational use or a 3516 in heavy-duty operations, proper alignment of the engine’s capabilities with your vessel’s needs ensures reliable performance and cost-effective operation over the long term.

5. Warranty and Documentation

Overview

- Warranty Scope

- Service Records

- Ownership Transfer

Warranty Scope

- For newer vessels or engines, warranties may still be in effect and can cover both parts and labor, including critical components like turbochargers, cylinder heads, and cooling systems.

- However, for many Caterpillar engines commonly found on older vessels—such as the 3208, 3408, 3412, or 3508—warranties are no longer applicable due to age. In these cases, proper documentation and maintenance history are more important than warranty coverage.

- Even if a warranty has expired, understanding the type of coverage it originally provided (if documentation is available) can give insights into the engine’s intended durability and service expectations.

Service Records

- For older engines, detailed documentation of maintenance and repairs becomes the primary indicator of the engine’s reliability and remaining lifespan.

- Critical Details to Look For:

- Dates and details of routine maintenance tasks such as oil changes, cooling system flushes, and inspections for wear. Engines like the 3406 or 3208 benefit significantly from consistent oil changes to prevent wear.

- Major repairs or rebuilds, including the parts used, such as injectors, cylinder heads, and raw water pumps. For example, if a 3516 underwent a rebuild, it is crucial to know whether premium aftermarket or OEM-grade parts were used.

- Records of upgrades or retrofits, such as newer fuel systems or emissions-compliant components for the 3412or 3508, which can enhance performance and meet modern standards.

- If service records are incomplete or unavailable, have a professional surveyor or mechanic perform a thorough inspection to evaluate the engine’s current condition.

- Engines like the 8V53, 12V53, and 3116—often found on vessels more than 20 years old—may require extra scrutiny, as incomplete documentation could hide potential neglect or improper maintenance.

Ownership Transfer

- For used vessels with Caterpillar engines, the focus shifts from warranty transfer to verifying and transferring maintenance history.

- Service logs and documentation should be passed to the new owner to provide continuity of care for engines like the 3304, 3306, or C32. These records are essential for planning future maintenance and identifying any recurring issues.

- While warranties for older engines, such as the 3208 or 3406, are often no longer valid, the service history still plays a critical role in determining the engine’s resale value.

- Non-transferable warranties should be noted in the transaction, but their absence should not outweigh the importance of maintenance records, which are far more relevant for older engines.

For Engines Without Warranties

- Many customers operate vessels with Caterpillar engines that are well over 20 years old, such as the 3208, 3412, or 3508, where warranty coverage is no longer applicable.

- Focus on Documentation: Detailed records of maintenance and repairs are the only reliable measure of an engine’s reliability and future performance.

- Evidence of Care: Look for evidence of regular servicing intervals, such as oil and filter changes, raw water pump replacements, and valve adjustments.

- Rebuild History: For engines like the 3512 or 3408, verify whether they have undergone major rebuilds and ensure that high-quality parts were used during the process.

- Inspection Recommendations: If no documentation is available, insist on an inspection by a qualified marine mechanic. This is particularly important for older engines, as undocumented issues could lead to significant repair costs.

Additional Considerations for Older Engines

- Documentation is critical for negotiating the price of older vessels. Engines like the 3306 or 12V71 may still perform reliably, but incomplete records could suggest potential risks.

- Maintenance records can also help establish the timeline for future repairs or rebuilds, such as when injectors, turbochargers, or water pumps may need to be serviced.

- Even without warranties, sourcing high-quality aftermarket parts, such as those from Diesel Pro Power, ensures the continued reliability of these older engines.

By focusing on Service Records, assessing Ownership Transfer requirements, and accepting that most older Caterpillar engines lack warranty coverage, vessel operators and buyers can still ensure confidence in their purchases. For engines like the 3208, 3408, or 3516, detailed documentation is often more valuable than a warranty, providing the critical insights needed to maintain reliable performance.

6. Compliance and Environmental Standards

Overview

- Environmental compliance ensures legal operation.

- Caterpillar engines often meet Tier 3 or Tier 4 standards.

- Retrofitting may be required for older engines.

Emissions Standards

- Compliance with emissions regulations is critical for legal operation, especially in regions with strict environmental standards. Many modern Caterpillar engines, such as the C32 or C18, meet or exceed Tier 3 and Tier 4 standards, ensuring reduced emissions and improved environmental performance.

- For older models like the 3208 or 3408, emissions compliance may require additional measures, as these engines were built before modern standards were established.

- Operating a non-compliant engine can result in fines, restrictions, or even the inability to operate in certain waters. Check the specific regulations for the regions where the vessel will be used.

Noise Pollution

- Noise pollution is a concern for both recreational and commercial vessels. Modern Caterpillar engines are designed to minimize noise, making models like the 3412 or 3516 suitable for use in marinas, harbors, or areas with noise restrictions.

- Older engines, such as the 3304 or 3406, may produce higher noise levels, which can be disruptive in certain environments. Consider retrofitting noise-reducing components like mufflers or insulation if quieter operation is required.

- Recreational boaters should verify noise specifications, especially if operating in areas with sensitive wildlife or residential restrictions.

Retrofit Options

- Retrofitting older engines to meet modern environmental standards is often necessary to comply with emissions or noise regulations. Retrofit kits for models like the 3508 or 3512 can include upgraded injectors, aftercoolers, or exhaust systems designed to reduce emissions and noise.

- Diesel Pro Power offers a variety of aftermarket parts for Caterpillar engines that can help improve environmental compliance while maintaining performance.

- Evaluate the cost of retrofitting versus replacing the engine. In some cases, installing a newer, emissions-compliant engine like the C7 or C9 may be more cost-effective in the long term.

7. Total Cost of Ownership

Overview

- Evaluate initial cost versus long-term expenses.

- Maintenance and fuel efficiency affect operating costs.

- Downtime for repairs impacts overall value.

Purchase Price

- Caterpillar engines are known for their quality, but they come with a premium price. Models like the 3516 or C32are significant investments due to their high power and advanced features.

- When purchasing a used vessel, factor in the engine’s age, condition, and any potential rebuild costs. For example, older engines like the 3408 or 3208 may require immediate maintenance or retrofitting to ensure reliable performance.

- Balance the upfront cost with the expected performance and operating lifespan of the engine. A slightly higher investment in a well-maintained or recently rebuilt engine can save money over time.

Operating Costs

- Fuel consumption, routine maintenance, and unexpected repairs all contribute to the total cost of ownership.

- Engines like the 3406 or C18 are designed for efficiency, but maintenance costs can increase if routine servicing is neglected.

- Unexpected repairs, such as replacing a raw water pump or turbocharger, can disrupt operations and add to overall expenses.

- Budget for routine maintenance and inspections to minimize unexpected costs and downtime.

Depreciation

- Caterpillar engines hold their value well when properly maintained. Regular upkeep, including oil changes, valve adjustments, and cooling system maintenance, minimizes depreciation.

- Older engines like the 3412 or 3306 may depreciate faster without a strong service record, but their inherent durability can still make them valuable for secondary applications.

- Investing in high-quality aftermarket parts can also preserve the engine’s value by maintaining performance and reliability.

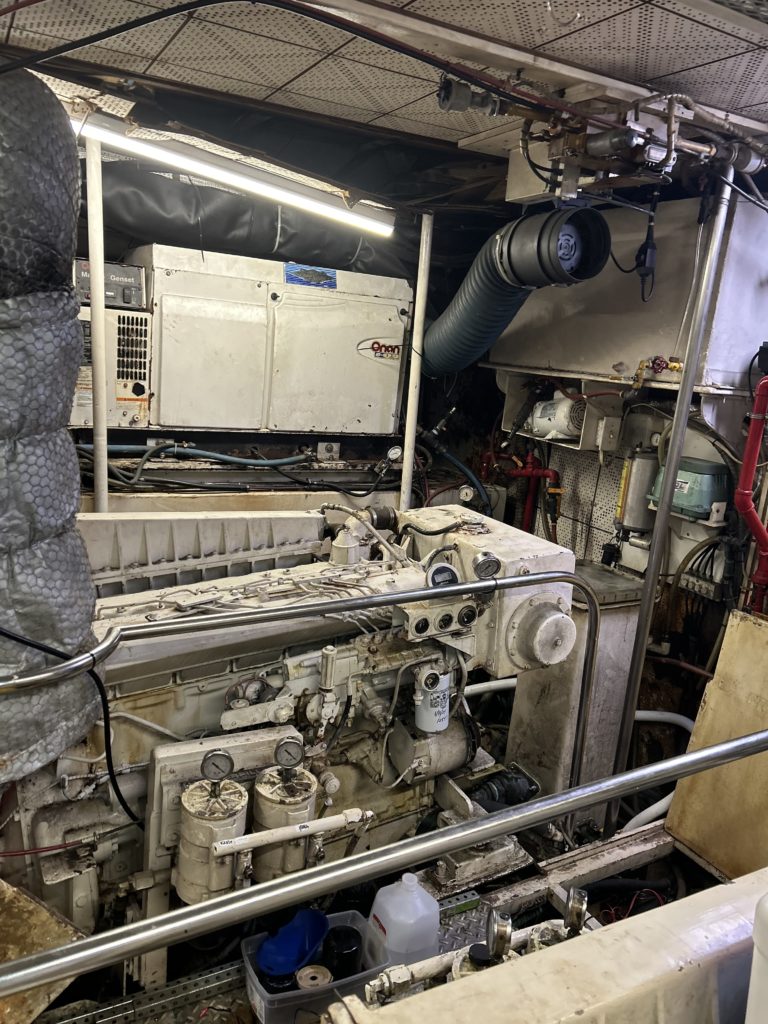

8. Vessel Condition

Overview

- The engine is only one component of the vessel.

- Hull integrity and design influence engine performance.

- Neglect in other areas may lead to costly repairs.

Hull Design

- A poorly designed or damaged hull can place excessive strain on the engine, reducing efficiency and increasing wear.

- Inspect the hull for structural integrity, balance, and hydrodynamic efficiency. Issues like uneven weight distribution or drag-inducing design flaws can cause engines like the 3406 or 3512 to work harder than necessary.

Age of Vessel

- Older vessels often hide issues such as corrosion, structural damage, or outdated components that can negatively impact engine performance.

- Conduct a thorough survey of the vessel, including electrical systems, plumbing, and propulsion compatibility with engines like the C18 or 3208.

- Plan for upgrades or repairs to other systems, as they may directly or indirectly affect the engine’s reliability and efficiency.

Propulsion System

- The propulsion system, including the gearbox, propeller, and drive shafts, must be compatible with the engine. Mismatched systems can reduce efficiency and reliability.

- Engines like the 3516 or C32 require heavy-duty propulsion systems to handle their high torque output. Ensure all components are designed to work together seamlessly.

10. Expert Evaluation

Overview

- Rely on professionals for thorough assessments.

- A marine surveyor ensures the vessel’s condition aligns with its value.

- Mechanics provide detailed insights into the engine’s health.

Marine Surveyor

- Hiring a certified marine surveyor is essential when purchasing a vessel. They will evaluate the overall condition of the hull, engine, and systems to ensure there are no hidden defects.

- A surveyor can also assess the value of the vessel and provide an estimate of necessary repairs or upgrades. For engines like the 3408 or 3412, they can help identify signs of wear or neglect that might not be immediately visible.

Trusted Mechanic

- A mechanic specializing in Caterpillar engines can provide a detailed evaluation of the engine’s health, including compression tests, diagnostics, and inspections of critical components like injectors and turbochargers.

- Their expertise is particularly valuable for older engines, such as the 3208 or 3512, where hidden wear or improper maintenance may impact reliability.

Test Runs

- Requesting a sea trial or test run is crucial to observe the engine’s real-world performance. Pay attention to:

- Acceleration and smoothness of operation.

- Unusual noises, vibrations, or smoke, which could indicate underlying issues.

- Compatibility with the vessel’s propulsion system under load conditions.

- A test run can highlight any immediate concerns and help you make an informed decision about the engine’s suitability for your needs.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588