Introduction: What You Need to Know About Cummins 6BT Sea Water Pumps

The Cummins 6BT marine diesel engine is one of the most widely used engines in commercial and recreational marine applications. Known for its reliability, simplicity, and abundant parts availability, the 6BT powers everything from fishing boats to small tugboats, pilot vessels, and pleasure crafts. A key component that ensures this engine stays cool and continues to run at optimal temperature is the sea water pump, also referred to as the raw water pump.

The seawater pump circulates raw water from outside the hull through the engine’s heat exchanger or aftercooler and back out of the vessel. If this pump fails, the engine can overheat rapidly—leading to catastrophic failure. For this reason, replacing or upgrading a worn seawater pump on your Cummins 6BT is a critical maintenance task.

This detailed guide covers everything you need to know to properly install a new seawater pump on your 6BT marine engine. Whether you’re a marine mechanic, boat owner, or commercial operator, follow this process to keep your Cummins 6BT performing reliably on the water.

Tools and Materials Needed

Tools and Materials Needed

Before starting the installation, make sure you have the following tools and materials on hand:

Basic Tools:

-

Ratchet and socket set (metric and SAE)

-

Wrenches (open-end and combination)

-

Flathead and Phillips screwdrivers

-

Torque wrench (with inch-pound and foot-pound settings)

-

Pliers and hose clamp pliers

-

Gasket scraper or razor blade

-

Thread sealant or pipe dope

-

Marine grease or anti-seize compound

Replacement Parts:

-

Replacement seawater pump for Cummins 6BT marine engine

-

New mounting gasket or O-ring (depending on pump style)

-

New hose clamps (stainless steel recommended)

-

Replacement impeller (if not pre-installed in the pump)

Safety Equipment:

-

Gloves

-

Safety glasses

-

Spill absorbent pads or drip trays

-

Bucket or drain pan

Step 1: Safety First – Engine Shutdown and Prep

-

Shut down the engine and allow it to cool completely. Never work on a hot engine, especially one circulating seawater, which can retain heat in the heat exchanger and hoses.

-

Turn off the battery disconnect switch or disconnect the negative terminal from the battery to avoid accidental starts.

-

Close the seacock (raw water intake valve) to prevent water from flowing into the bilge once hoses are removed.

-

Place absorbent pads or drip trays under the pump location to catch any coolant or seawater.

-

Drain the seawater from the system if necessary, using a bucket or drain pan under the pump inlet hose.

Step 2: Locate and Remove the Old Seawater Pump

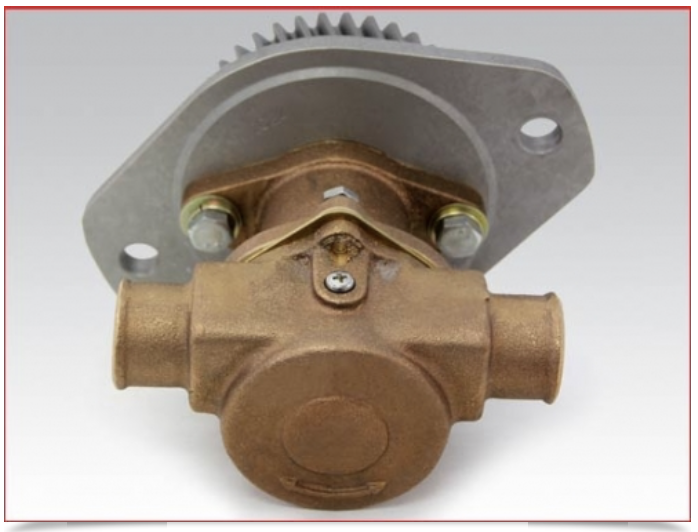

Raw Water Pump For Cummins 6BT Outlet: 1 3/4” Hose Inlet: 2” Hose

The seawater pump on the 6BT is typically mounted to the front gear housing and is driven either by a gear or V-belt depending on the model variant.

-

Identify the pump location on the front right side of the engine (looking from the flywheel end). The pump body will have a hose connected to the inlet (from the seacock) and outlet (to the heat exchanger or aftercooler).

-

Mark or photograph hose locations to ensure correct reassembly.

-

Loosen and remove hose clamps on the inlet and outlet hoses using pliers or a screwdriver.

-

Carefully twist and pull hoses free. If they are seized on, gently work them loose with a pick or flathead screwdriver, being cautious not to damage the fitting.

-

Remove the mounting bolts securing the pump to the engine front cover using the appropriate socket or wrench.

-

Gently pull the pump straight out. Some coolant may leak—this is normal. Remove any old gasket material left on the mounting surface with a scraper.

Step 3: Prepare the New Pump for Installation

-

Inspect the new pump to confirm it matches your old unit. Compare shaft lengths, bolt patterns, hose fitting locations, and impeller chamber orientation.

-

Install a new impeller if it’s not already pre-installed in the pump housing. Apply a light coating of glycerin or impeller lube to help with startup.

-

Install a new gasket or O-ring on the mounting surface. Do not reuse the old gasket. If your new pump has a machined groove for an O-ring, use marine grease to hold it in place during installation.

-

Apply anti-seize to the pump’s mounting bolts to prevent corrosion and make future removal easier.

-

Inspect the drive gear or pulley (if equipped) for wear, misalignment, or missing teeth. Replace or service it as needed.

Step 4: Install the New Seawater Pump

-

Position the new pump onto the front cover carefully. Align the drive gear or shaft splines as needed.

-

Hand-thread mounting bolts and torque them in a star pattern to ensure even pressure. Torque specs for Cummins 6BT seawater pump mounting bolts typically range from 18–24 ft-lbs (24–33 Nm)—refer to your service data.

-

Reinstall inlet and outlet hoses, making sure they are clean and free of cracks or debris. Secure tightly with marine-grade stainless steel hose clamps.

-

Double-check the orientation of the pump body and ensure that hose routing is not kinked or under strain.

Step 5: System Priming and Leak Check

-

Open the seacock to allow raw water to enter the system.

-

Reinstall the battery connection or turn the battery switch back on.

-

Start the engine and immediately check for leaks at:

-

Hose fittings

-

Pump mounting surface

-

Shaft seal or weep hole (small vent hole in pump body)

-

-

Check for flow at the discharge port (raw water outlet through the hull). A steady stream should be visible within seconds.

-

Let the engine run for 5–10 minutes and monitor engine temperature, which should remain in the optimal range of 160°F to 180°F (71°C to 82°C).

-

Shut down the engine and re-check all fittings for tightness.

Step 6: Post-Installation Maintenance Tips

To maximize the life of your new 6BT seawater pump, consider these best practices:

-

Inspect pump impeller every 100 hours or seasonally. Impellers degrade with time even if not used.

-

Flush the system with fresh water after each use in saltwater conditions to prevent corrosion and calcium buildup.

-

Keep a spare impeller and gasket onboard—especially for offshore or remote boating applications.

-

Lubricate impeller housing during storage to prevent impeller vanes from sticking.

-

Check for seawater drips near the shaft seal area regularly. This can indicate a worn seal and early pump failure.

Common Installation Mistakes to Avoid

-

Over-torquing bolts: Excess torque can warp the pump flange or damage the gasket.

-

Misaligning drive gear: Improper alignment can strip the gear or cause noise and early failure.

-

Using the wrong gasket: A mismatched gasket can lead to leaks or loss of prime.

-

Ignoring hose condition: Cracked or soft hoses can leak even when clamped.

-

Skipping system priming: Dry-running a new pump will destroy the impeller in seconds.

-

Not checking flow at the outlet: Just because the engine is running doesn’t mean water is moving through the cooling system.

Symptoms of a Failing Seawater Pump

Recognizing the signs of a failing seawater pump early can prevent severe engine damage:

-

High engine temperature

-

Decreased water flow from discharge outlet

-

Squealing or grinding noises from pump

-

Leaking around pump body or shaft

-

Discolored or milky oil (in rare cases of water intrusion)

If you encounter any of these issues, shut down the engine and inspect the seawater pump immediately.

OEM vs Aftermarket Seawater Pumps

At Diesel Pro Power, we offer premium aftermarket seawater pumps for the Cummins 6BT that meet or exceed OEM specifications. Here’s why many commercial operators choose aftermarket pumps:

-

Lower cost without sacrificing performance

-

OEM-matching fit and design for plug-and-play installation

-

Availability of complete pump or pump with impeller only

-

Extended warranty options

-

In-stock and ready to ship worldwide

To match your pump correctly, refer to the engine serial number or call our technical team for compatibility support.

Applications and Fitment Overview

The Cummins 6BT is used in a wide variety of marine applications, and pump configurations may vary depending on:

-

Aftercooler setup (with or without)

-

Heat exchanger design

-

Commercial vs recreational duty

-

Straight shaft vs gear-driven pump

Popular vessels that use the 6BT include:

-

Charter fishing boats

-

Dive boats

-

Small tugboats

-

Pilot boats

-

Trawlers

-

Workboats

-

Power catamarans

Always verify the inlet/outlet orientation, shaft style, and mounting type when selecting a replacement seawater pump.

FAQ – Frequently Asked Questions

1. How do I know if my Cummins 6BT uses a belt-driven or gear-driven seawater pump?

Inspect the pump front. Belt-driven models have a pulley and belt; gear-driven models mount directly into the timing gear housing.

2. How often should I replace the seawater pump?

The pump body can last 1,000+ hours with proper care, but impellers should be inspected or replaced every 100–250 hours or annually.

3. Should I replace the impeller or the whole pump?

If the housing, bearings, or shaft seals show wear or corrosion, replacing the entire pump is the safest choice.

4. Can I use a generic marine water pump?

No. The Cummins 6BT pump has specific mounting, flow, and shaft specs. Use a pump designed specifically for the 6BT engine.

5. What is the difference between raw water and freshwater pumps?

Raw (sea) water pumps pull water from outside the hull. Freshwater pumps circulate coolant internally through the engine.

6. What size hose fittings are on the 6BT seawater pump?

Most use 1.25” or 1.5” hose barbs, but always confirm your model before ordering.

7. Can I change the seawater pump while the engine is mounted in the boat?

Yes. Most installations provide enough front-end access to replace the pump without removing the engine.

8. Do I need to use gasket sealant on the new pump?

If using a flat gasket, a light coat of sealant helps. O-ring models do not require sealant.

9. What should I do if I see seawater leaking from the weep hole?

Replace the pump. This indicates the internal shaft seal has failed.

10. Where can I buy a replacement seawater pump for my Cummins 6BT?

Visit Diesel Pro Power for in-stock aftermarket seawater pumps, fast shipping, and technical support.

Diesel Pro Power has an enormous inventory of Cummins Engine Parts. We also carry tons of raw water pumps for Cummins.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588