Introduction: What You Need to Know About Sea Water Pumps For Cummins 6CTA

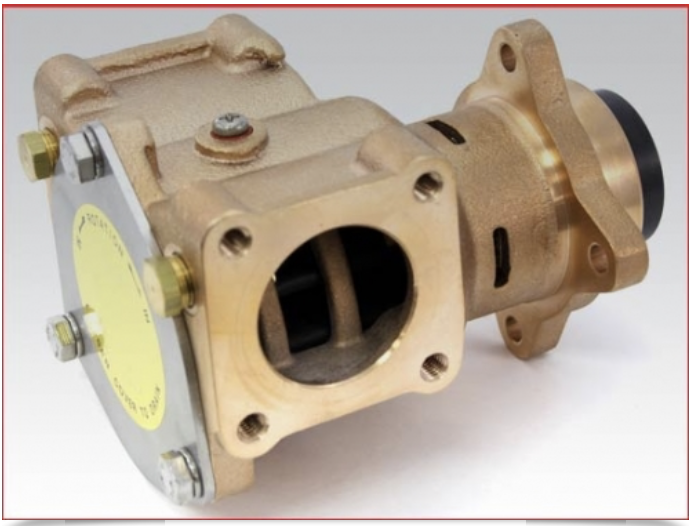

For Cummins marine engines, especially the widely used 6CTA 8.3 series, the sea water pump is a mission-critical component. It’s responsible for drawing raw (sea) water through the heat exchanger system to keep the engine at proper operating temperature. Without a fully functional sea water pump, your engine would quickly overheat, leading to serious damage.

Whether you’re a commercial captain, private yacht owner, or professional marine mechanic, understanding how to select, install, maintain, and troubleshoot a Cummins 6CTA sea water pump is essential to protect your investment and keep your vessel ready for duty.

This guide gives you everything you need to know for practical, real-world servicing and replacement. While it pulls extensively from Cummins technical standards and marine maintenance best practices, always remember that for precise tolerances, torque values, and detailed diagrams, you should consult the official Cummins service manual for the 6CTA engine.

Types of Sea Water Pumps For Cummins 6CTA

Before you start planning an installation or replacement, it’s vital to understand that there are three primary styles of sea water pumps used on Cummins 6CTA engines. Selecting the right style is critical for proper fitment and reliable operation.

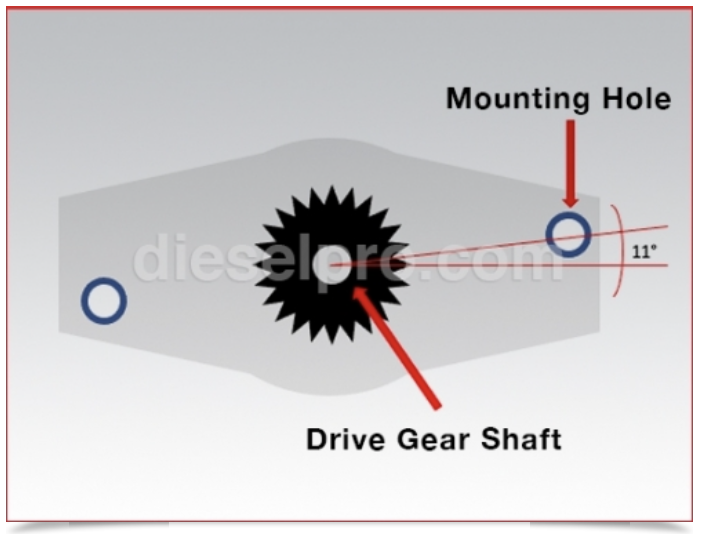

1. Sea Water Pump With 11° Offset Mounting Holes From The Center Of The Drive Gear Shaft For Cummins 6CTA

This pump has its mounting holes positioned 11 degrees offset from the center of the drive gear shaft. This detail is small but extremely important, as mounting holes that don’t align will prevent proper sealing or even damage the pump body or engine cover during tightening.

This style requires:

-

2. Sea Water Pump With 16° Offset Mounting Holes Off The Center Shaft For Cummins 6CTA

In this version, the mounting holes are 16 degrees offset from the center shaft, again emphasizing the importance of verifying before purchase. Using the incorrect style can result in leaks or catastrophic failures under load.

This style also uses:3. Bidirectional Sea Water Pump (Right or Left Rotation) For Cummins 6CTA

This type is designed to turn either direction — clockwise or counterclockwise — making it more versatile for certain marine configurations.

It requires:-

Uses the bolts from your old pump for installation

It’s recommended that before removing your old pump, you take clear photos and note the rotation, mounting orientation, and hose positions. This ensures that when installing the new pump, you can replicate the exact configuration needed for your cooling system.

Preparing for Installation (Site and Materials) For Cummins 6CTA

Proper preparation is half the job done. Here’s what you’ll need and what to inspect before installing or replacing your Cummins 6CTA sea water pump.

Tools & Materials Checklist

-

New sea water pump of correct style (verify 11°, 16°, or bidirectional)

-

Mounting gasket (if applicable)

-

Inlet & outlet port seals (always replace these)

-

Your original bolts (unless damaged — if so, replace with exact grade)

-

Socket wrench and appropriate metric sockets

-

Torque wrench (refer to service manual for exact torque)

-

Clean rags and degreaser

-

Marine-grade thread sealant (for certain installations)

-

A small container to catch residual seawater

Preparation Steps

-

Engine Cooldown: Always start with a cold engine. Working on a hot cooling system can cause burns or force you to drain coolant under pressure.

-

Shut Valves: Close the sea water inlet valves to prevent flooding when hoses are removed.

-

Check Old Pump: Verify style and take photos. Inspect old hoses for cracks or swelling — replace if needed.

-

Lay Out Workspace: Organize tools and keep new seals and gaskets clean and dry until ready to install.

Removing the Old Sea Water Pump For Cummins 6CTA

Follow these general steps, always keeping safety and cleanliness in mind.

Basic Removal Process

-

Drain Sea Water: Remove the inlet and outlet hoses from the sea water pump, allowing any residual water to drain into a container.

-

Mark Hoses: Use masking tape to label hoses (IN vs OUT) to avoid reversal.

-

Remove Mounting Bolts: Use your socket wrench to carefully remove the bolts holding the pump to the engine block. Keep bolts in a clean tray.

-

Remove Old Pump: Gently pull the pump away. If it sticks, wiggle by hand — avoid prying with metal tools that could damage sealing surfaces.

-

Clean Surface: Scrape off any old gasket material carefully and wipe with a clean rag and degreaser to prepare for the new gasket.

Installing the New Sea Water Pump For Cummins 6CTA

Key Points Before You Bolt It On

-

Always use new gaskets and seals. Reusing old ones is false economy and can cause leaks.

-

Lightly oil or use recommended sealant on the gasket if the service procedure requires it.

-

Ensure alignment pins or guides are in position if your configuration uses them.

Step-By-Step Installation

-

Position the New Pump: Align the new pump with the engine block, making sure the offset holes (11° or 16°) match your specific engine.

-

Hand-Thread Bolts: Start all bolts by hand to avoid cross-threading.

-

Tighten Evenly: Snug bolts in a crisscross pattern. This evenly compresses the gasket.

-

Torque Bolts: Use a torque wrench to tighten to the Cummins specification found in your service manual. This prevents leaks and warping.

Reconnecting Hoses

-

Slide the inlet and outlet hoses back on.

-

Secure with high-quality marine hose clamps — double clamp larger hoses for redundancy.

-

Ensure clamps are tight but do not cut into the hose.

Reopen Valves & Inspect

-

Slowly reopen the sea water inlet valves to fill the circuit.

-

Check visually for drips or seepage before starting the engine.

Testing Your Cummins 6CTA Sea Water Pump System For Cummins 6CTA

Once installed, testing is critical. Running without verifying can risk an immediate overheat if something was missed.

Static Leak Check

-

Open seacock fully with the engine off.

-

Check around the new pump, hose connections, and seacock fittings for leaks.

Engine Warm-Up Check

-

Start the engine and let it idle. Watch for leaks as the system pressurizes.

-

Feel the discharge hose — it should begin to warm as water circulates through the heat exchanger.

Sea Trial or Under-Load Check

-

Take the boat out at normal cruising speed.

-

Monitor engine temperature closely.

-

Stop and check bilge for leaks around the pump area.

Sea Water Pressure Test (Advanced)

Some marine mechanics perform a sea water pressure check using gauges at the inlet or outlet to confirm flow is within Cummins specs. If you suspect restricted flow, impeller issues, or partial blockages, this is the next diagnostic step.

Maintenance Tips and Common Checks For Cummins 6C, 6CT, & 6CTA

To get the longest life from your Cummins 6CTA sea water pump:

-

Inspect Seals & Weep Hole: Periodically check the weep hole on the pump for signs of salt crust or moisture — early warnings of seal failure.

-

Replace Impeller Annually: Even if it’s not failed, preventative replacement minimizes risk.

-

Flush System: Especially important if operating in silty or sandy water.

-

Monitor Temperature Gauges: An unexplained rise may mean partial restriction or pump inefficiency.

Additional Notes on Gaskets, Seals, and Mounting For Cummins 6CTA

-

The Cummins 6CTA uses specific mounting gaskets depending on the pump style. Always confirm the part number with your supplier.

-

The inlet and outlet port seals are critical. Even a tiny nick can allow air into the system, reducing suction efficiency and causing overheating under load.

-

Always torque bolts to Cummins specs. Over-tightening can crush gaskets; under-tightening can lead to leaks.

Troubleshooting Common Issues After Replacement For Cummins 6CTA

If engine temperature is higher than normal:

-

Ensure the pump is rotating in the correct direction (especially important with bidirectional pumps).

-

Check for air leaks on the suction side.

-

Verify that hoses are not collapsing under suction (old soft hoses can collapse internally).

-

Ensure no partial blockage in the sea strainer.

If you see water leaking from the pump body:

-

Likely failed seal — inspect the weep hole for salt deposits.

-

Confirm gasket was installed correctly and mounting bolts were evenly torqued.

If you hear unusual noises:

-

Could indicate impeller damage from debris.

-

Remove pump and inspect impeller vanes for breakage.

Disclaimer For Cummins 6CTA

This guide provides practical field-oriented insights based on common Cummins 6CTA marine installations. It is not a replacement for the detailed specifications, torque values, and model variations found in the official Cummins service manual. Always consult your Cummins service manual for the precise instructions applicable to your CPL or marine rating.

Conclusion: Protect Your Engine Investment For Cummins 6CTA

Your Cummins 6CTA sea water pump does the critical work of keeping your engine cool, protecting it from the devastating consequences of overheating. By understanding the different pump styles, preparing your installation carefully, using proper gaskets and seals, and performing diligent testing and maintenance, you’ll extend the life of your pump — and your engine.

Stay vigilant with periodic inspections and proactive servicing. A properly installed and maintained sea water pump means confidence every time you fire up your Cummins-powered vessel, whether for commercial duty or weekend cruising.

Additional Resources For The Cummins 6CTA

Marine Cummins 6CTA Component Maintenance Life

Cummins 6CTA 8.3 Marine Diesel Engine Specifications

A Comprehensive Guide to Cummins 6CTA Diamond Series Diesels 8.3 Parts and Maintenance

Buy Parts For Your Cummins 6CTA 8.3L

Guide To Buying A Cummins 6CTA Overhaul Kit

A Step-by-Step Guide to Installing a Cummins 6CTA Sea Water Pump

The Cummins 6CTA Marine Diesel Engine

Regular Service For Cummins 6CTA

Boats That Use The Cummins 6CTA

FAQ About The Cummins 6CTA Engine

Torque Specs For Cummins 6CTA 8.3

Cummins C Series Engine Comprehensive FAQ

Overview of Cummins C Series Engines (6C, 6CT, 6CTA) (1991 and 1994 Certification Levels)

Key Features of Cummins C Series Engines (6C, 6CT, 6CTA)

Tools and Preparation for Servicing Your Cummins 6C, 6CT, 6CTA

Engine Overhaul Basics for Cummins C Series Engines (6C, 6CT, 6CTA)

Comparing 1991 and 1994 Certification Levels for Cummins C Series Engines (6C, 6CT, 6CTA)

Understanding the Basics for Cummins 6C, 6CT, & 6CTA

Maintenance Essentials for Cummins 6C, 6CT, & 6CTA Engines

System Specific Servicing for Cummins 6C, 6CT, & 6CTA Engines

Advanced Repairs for Cummins 6C, 6CT, & 6CTA Engines

Certification Level Specific Insights for Cummins 6C, 6CT, & 6CTA Engines

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588