Freshwater Pumps For Cummins Engines

Freshwater pumps play a crucial role in the cooling system of Cummins engines. Freshwater pumps for Cummins engines are responsible for circulating coolant throughout the engine, preventing it from overheating and ensuring optimal performance. Without a properly functioning freshwater pump, the engine would be unable to dissipate the heat generated during operation, leading to overheating and potential engine failure.

In this guide, we will explore the different types of freshwater pumps used in Cummins engines, their function, installation, and maintenance. Additionally, we will provide key insights into how to select the right pump for your Cummins engine, ensuring longevity and peak performance.

The Importance of Freshwater Pumps in Cummins Engines

Cummins engines are known for their durability and efficiency, but like any internal combustion engine, they generate a significant amount of heat during operation. The cooling system is designed to manage this heat, with the freshwater pump playing a central role.

The primary function of a freshwater pump in a Cummins engine is to circulate coolant through the engine block, absorbing excess heat and transferring it to the radiator or heat exchanger. This process prevents the engine from overheating and helps maintain the ideal operating temperature for optimal performance and fuel efficiency.

Without a functioning freshwater pump, the engine’s temperature would quickly rise to dangerous levels, leading to:

- Reduced performance

- Increased fuel consumption

- Premature engine wear

- Potential catastrophic engine failure

Therefore, choosing the right freshwater pump and ensuring proper installation and maintenance are vital for the longevity of your Cummins engine.

Types of Freshwater Pumps for Cummins Engines

Cummins engines use different types of freshwater pumps, each with unique characteristics. The three most common types are:

1. Centrifugal Pumps

Centrifugal pumps are widely used in Cummins engines due to their efficiency and high flow rate. These pumps operate by using a rotating impeller to move coolant through the engine.

Advantages of Centrifugal Pumps:

- High flow rate, ensuring rapid heat dissipation

- Quiet operation, making them ideal for marine and industrial applications

- Low maintenance requirements

Disadvantages:

- Less effective at low speeds

- Sensitive to cavitation, which can lead to pump damage

2. Gear Pumps

Gear pumps are another common type of freshwater pump used in Cummins engines. These pumps operate by using interlocking gears to move coolant through the system.

Advantages of Gear Pumps:

- Provides a steady flow of coolant, even at high engine speeds

- Durable and capable of handling high-pressure applications

- Long lifespan due to robust design

Disadvantages:

- Noisy compared to centrifugal pumps

- More complex maintenance and repair process

3. Impeller Pumps

Impeller pumps use flexible rubber impellers to move coolant. These pumps are commonly found in marine applications and are known for their ability to provide excellent cooling performance.

Advantages of Impeller Pumps:

- Efficient cooling performance

- Self-priming capability, making them ideal for marine environments

- Easy to replace when worn out

Disadvantages:

- Rubber impellers wear out over time and require periodic replacement

- Less durable in high-pressure applications

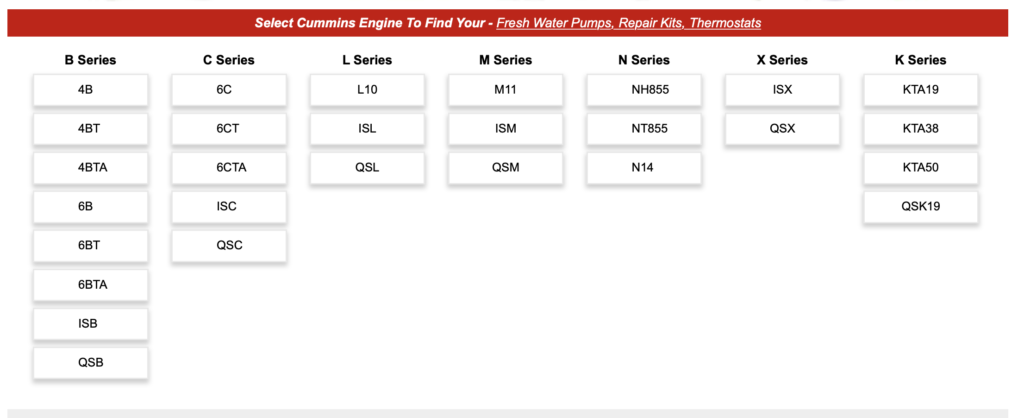

How to Find the Right Freshwater Pump for Your Cummins Engine

Choosing the correct freshwater pump for your Cummins engine is crucial for ensuring optimal cooling performance. Here are some factors to consider when selecting a replacement pump:

1. Engine Model Compatibility

Not all freshwater pumps are interchangeable. Ensure that the pump you select is designed specifically for your Cummins engine model. Check the engine’s specifications or consult your parts supplier for compatibility information.

Freshwater Pump for 4B Cummins Marine Engine

Freshwater Pump for 4BT Cummins Marine Engine

Freshwater Pump for 4BTA Cummins Marine Engine

Freshwater Pump for 6B Cummins Marine Engine

Freshwater Pump for 6BT Cummins Marine Engine

Freshwater Pump for 6BTA Cummins Marine Engine

Freshwater Pump for ISB 4.5 Cummins Marine Engine

Freshwater Pump for ISB 5.9 Cummins Marine Engine

Freshwater Pump for ISB 6.7 Cummins Marine Engine

Freshwater Pump for QSB 4.5 Cummins Marine Engine

Freshwater Pump for QSB 5.9 Cummins Marine Engine

Freshwater Pump for QSB 6.7 Cummins Marine Engine

Freshwater Pump for 6C Cummins Marine Engine

Freshwater Pump for 6CT Cummins Marine Engine

Freshwater Pump for 6CTA Cummins Marine Engine

Freshwater Pump for ISC Cummins Marine Engine

Freshwater Pump for QSC Cummins Marine Engine

Freshwater Pump for M11 Cummins Marine Engine

Freshwater Pump for ISM Cummins Marine Engine

Freshwater Pump for QSM Cummins Marine Engine

Freshwater Pump for NH855 Cummins Marine Engine

Freshwater Pump for NT855 Cummins Marine Engine

Freshwater Pump for N14 Cummins Marine Engine

Freshwater Pump for ISX Single Cam Cummins Marine Engine

Freshwater Pump for ISX Dual Cam Cummins Marine Engine

Freshwater Pump for QSX Cummins Marine Engine

Freshwater Pump for KTA19 Cummins Marine Engine

Freshwater Pump for KTA38 Cummins Marine Engine

Freshwater Pump for KTA50 Cummins Marine Engine

Freshwater Pump for QSK19 Cummins Marine Engine

2. Flow Rate Requirements

Different engines require different coolant flow rates. Selecting a pump with the appropriate flow rate ensures that your engine remains within the optimal temperature range.

3. Material and Durability

Freshwater pumps are made from various materials, including cast iron, aluminum, and stainless steel. For marine applications, corrosion-resistant materials like stainless steel are recommended to withstand exposure to seawater.

4. OEM vs. Aftermarket Pumps

While OEM (Original Equipment Manufacturer) pumps are often preferred for their quality, high-quality aftermarket options can provide the same performance at a lower cost. It’s important to choose an aftermarket pump from a reputable supplier to ensure reliability.

5. Installation Requirements

Some pumps require additional mounting hardware or modifications for installation. Checking the installation requirements beforehand will help ensure a smooth replacement process.

Find The Right Freshwater Pump For Your Cummins Engine

The design of the fresh water pump for Cummins engines is very important. The pump must be designed to ensure that the coolant is delivered in the right amounts, at the right pressure, and in the right direction. The pump must also be designed to ensure that it can handle the high temperatures that are present in a Cummins engine.

The installation of a fresh water pump for Cummins engines is also very important. It is important that the pump is installed correctly and securely. The pump should be inspected regularly to make sure that it is free from any blockages. It is also important to check the mounting bolts and ensure that they are tight and secure.

In conclusion, fresh water pumps are an essential component of Cummins engines. They help to ensure that the engine is operating at its optimal performance. The design and installation of the pump is also important in order to ensure that the coolant is delivered in the right amounts, at the right pressure, and in the right direction. Regular inspection and maintenance of the pump is also important in order to ensure that it is free from any blockages.

Installation Tips for Freshwater Pumps on Cummins Engines

Proper installation of a freshwater pump is essential for efficient operation. Follow these steps for a successful installation:

1. Gather Necessary Tools and Parts

Before starting, ensure you have the correct replacement pump, gaskets, seals, and necessary tools. A service manual can be helpful for reference.

2. Drain the Coolant System

Before removing the old pump, drain the engine coolant to prevent spills and contamination.

3. Remove the Old Pump

- Disconnect the pump’s hoses and mounting bolts.

- Carefully remove the pump, ensuring no debris enters the cooling system.

4. Clean the Mounting Surface

Thoroughly clean the mounting area to ensure a proper seal with the new pump.

5. Install the New Pump

- Position the new pump and secure it with the mounting bolts.

- Attach the coolant hoses and ensure they are properly secured.

6. Refill and Bleed the Cooling System

- Refill the cooling system with fresh coolant.

- Start the engine and allow it to reach operating temperature while checking for leaks.

- Bleed any trapped air from the system to prevent overheating.

7. Perform a Final Inspection

Check the pump’s operation and inspect for leaks before completing the installation.

Maintenance and Troubleshooting

Regular maintenance is key to ensuring the longevity and efficiency of your Cummins engine’s freshwater pump.

Maintenance Tips:

- Inspect Regularly: Check for leaks, corrosion, or unusual noises.

- Replace Worn Parts: Impellers, gaskets, and seals should be replaced as needed.

- Flush the Cooling System: Periodically flush the coolant system to remove debris and prevent clogging.

- Monitor Coolant Levels: Low coolant levels can cause overheating and damage the pump.

Common Problems and Solutions

| Problem | Possible Cause | Solution |

|---|---|---|

| Overheating | Low coolant level or blocked pump | Check coolant and clean pump |

| Noisy Operation | Worn bearings or cavitation | Replace bearings or inspect flow rate |

| Coolant Leaks | Failing gasket or cracked housing | Replace gasket or pump |

| Weak Coolant Flow | Worn impeller or clogged passages | Replace impeller and clean system |

Conclusion

Freshwater pumps are an essential component of Cummins engines, ensuring proper cooling and optimal performance. Selecting the right pump, installing it correctly, and performing regular maintenance can prevent overheating and extend the lifespan of your engine.

By understanding the different types of freshwater pumps, their advantages, and best maintenance practices, you can ensure that your Cummins engine continues running efficiently for years to come. If you need a replacement pump, always choose a high-quality part that matches your engine’s specifications.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588