The Cummins 6CTA Overhaul Kit: Restore Your Engine with Confidence

Cummins engines are widely known for their exceptional power, efficiency, and longevity—and the Cummins 6CTA is no exception. Trusted in industrial, marine, and commercial vehicle applications around the world, the Cummins 6CTA has become a cornerstone of diesel engine reliability. However, even the most robust engines wear down over time. That’s where the Diesel Pro Power, Inc. Cummins 6CTA Overhaul Kit comes in.

This comprehensive overhaul kit provides all the essential components to rebuild and restore a Cummins 6CTA engine to optimal working condition. Whether you’re dealing with high engine hours, decreased performance, or simply want to ensure many more years of reliable service, a full engine overhaul is the most cost-effective way to achieve that goal. This article covers everything you need to know about the 6CTA overhaul kit, including its components, benefits, compatibility, and why Diesel Pro Power, Inc. is the trusted source for thousands of engine professionals worldwide.

What Is the Cummins 6CTA Engine?

The Cummins 6CTA is a 5.9-liter, inline six-cylinder, four-stroke diesel engine equipped with a turbocharger and intercooler. This configuration provides a balanced blend of power, efficiency, and cooling performance, making the 6CTA one of the most widely respected engines in its class. Its design promotes efficient combustion, robust torque delivery, and high endurance under demanding workloads.

Known for its exceptional versatility, the Cummins 6CTA is used across a wide spectrum of industries and equipment types, including:

- Marine propulsion systems: Ideal for commercial fishing boats, ferries, and auxiliary marine power units.

- Industrial equipment: Frequently found in cranes, compressors, pumps, and drilling rigs.

- Agricultural machinery: Powers tractors, combines, and irrigation systems with reliable output.

- Power generation: Operates as a dependable prime or standby generator engine.

- Medium-duty trucks and buses: Common in delivery fleets, municipal vehicles, and school buses.

Its strong reputation is built on high torque, excellent fuel economy, consistent performance, and ease of maintenance. The 6CTA’s mechanical simplicity and durable design mean fewer electronic components to fail and a lower overall cost of ownership. With regular servicing and high-quality replacement parts, the Cummins 6CTA can easily surpass 500,000 miles or deliver more than 20,000 engine hours, proving itself as a true workhorse in a range of tough environments.

In the video below our customer Imperial Diesel Service, LLC installs a Cummins 6CTA into a commercial fishing boat.

Why Choose a Diesel Pro Power, Inc. Overhaul Kit?

Diesel Pro Power, Inc. specializes in high-quality diesel engine components. Our Cummins 6CTA overhaul kits are meticulously curated to include only OEM-quality or superior aftermarket parts that meet or exceed original specifications. Each kit is engineered to provide a complete solution for engine restoration, removing the guesswork and ensuring consistency across components.

Choosing a Diesel Pro Power overhaul kit means:

- Access to all required components in one convenient package

- Cost savings compared to purchasing parts individually

- Compatibility assurance based on CPL (Control Parts List) numbers

- Premium-quality parts backed by a one-year warranty

- Trusted customer service and expert support

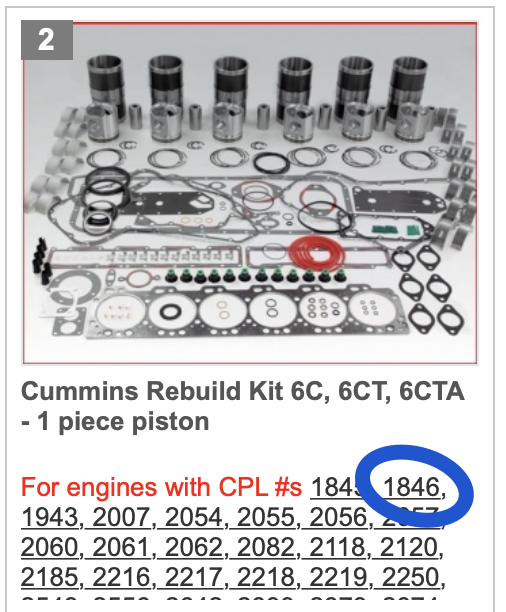

Identifying What Cummins 6CTA Overhaul Kit You Need

Use your engines CPL number to identify the correct overhaul kit for your engine.

Engine Overhual Kit for Cummins 6CTA

What Does the Cummins 6CTA Overhaul Kit Include?

A standard Diesel Pro Power overhaul kit for the Cummins 6CTA includes the following components:

Pistons (6 units): High-strength aluminum alloy pistons designed to withstand high pressures and temperatures while minimizing friction and wear.

Cylinder Liners (6 units): Precision-machined and induction-hardened liners that restore the cylinder bore to OEM tolerances.

Piston Rings (6 sets): Designed for optimal sealing, oil control, and heat dissipation, helping to restore compression and performance.

Piston Pins (6 units) and Retainers (12 units): Securely fasten the pistons to the connecting rods, allowing smooth rotational motion.

Crankshaft Main Bearings (1 set): High-durability bearings to support the crankshaft and absorb stress from combustion and load.

Connecting Rod Bearings (6 sets): Provide a friction-reducing interface between the connecting rods and crankshaft.

Upper Gasket Kit (1 unit): Includes cylinder head gasket, intake and exhaust gaskets, valve cover gasket, injector seals, and other necessary upper engine seals.

Lower Gasket Kit (1 unit): Contains oil pan gaskets, rear and front main seals, timing cover gasket, and other lower engine seals.

Parts That Are Sold Separately:

- Camshaft bushings for Cummins 6CTA

- Oil pump For Cummins 6CTA

- Fresh Water Pump For Cummins 6CTA

- Raw Water Pump For Cummins 6CTA

- Turbocharger & Related Parts For Cummins 6CTA

- Fuel Pumps & Related Parts For Cummins 6CTA

- Fuel Filters For Cummins 6CTA

- Fuel Injectors For Cummins 6CTA

- Oil Filters For Cummins 6CTA

The Benefits of a Cummins 6CTA Overhaul Kit

1. Cost-Effective Engine Restoration

An overhaul kit is significantly less expensive than buying a remanufactured engine or purchasing individual components. It delivers everything needed for a rebuild at a fraction of the cost.

2. Guaranteed Compatibility

When sourced through Diesel Pro Power and matched using your CPL number, every part is guaranteed to fit your specific engine configuration.

3. Improved Engine Life and Performance

Replacing worn pistons, rings, liners, and bearings restores factory-like compression and efficiency, often improving fuel economy and reducing emissions.

4. Simplified Ordering Process

No more chasing down individual parts from different vendors. Our kits ensure all essential components are delivered together, reducing downtime.

5. One-Year Warranty

Diesel Pro Power stands behind its products with a 12-month warranty on overhaul kits, giving you peace of mind during installation and operation.

6. OEM-Quality Assurance

Every component in our overhaul kits meets or exceeds Cummins OEM standards for material quality, dimensional accuracy, and performance.

When Should You Consider an Engine Overhaul?

Knowing when to rebuild a Cummins 6CTA engine is critical to avoiding catastrophic failure, unplanned downtime, and expensive repairs. A diesel engine overhaul involves disassembling the engine, inspecting and replacing worn components, and restoring the engine to a like-new condition. Overhauls are a proactive measure to extend the life of your equipment and maintain peak performance. While every engine will eventually need an overhaul, recognizing the right time to act can mean the difference between a smooth restoration and a costly emergency.

Here are the key indicators and scenarios when you should seriously consider overhauling your Cummins 6CTA engine:

1. Excessive Engine Hours

The Cummins 6CTA is known for its longevity, but no engine lasts forever. Most users report a practical overhaul interval at approximately 15,000 to 20,000 engine hours, depending on usage, maintenance practices, load cycles, and environmental conditions. For marine and industrial engines that run daily, these hours accumulate faster than one might expect. Delaying an overhaul beyond this range increases the risk of major failures such as piston scoring, cracked liners, or crankshaft damage.

If your engine is approaching or has surpassed 20,000 hours, it is wise to schedule a thorough inspection. Even if the engine is still running, components like bearings and rings may be operating at the edge of their tolerances, risking catastrophic failure with continued use.

2. Reduced Compression and Blow-By

Loss of compression is a telltale sign of internal wear. You may notice harder cold starts, poor throttle response, or a general loss of power. Reduced compression is often caused by worn piston rings, scuffed liners, or valve issues. One diagnostic sign is excessive blow-by, where combustion gases leak past worn piston rings and enter the crankcase. This results in increased crankcase pressure, oil mist from the breather tube, and soot contamination in the oil.

Excessive blow-by not only impacts performance but accelerates wear across engine components due to higher internal temperatures and contamination. A compression test or cylinder leak-down test can confirm these conditions and help guide the decision to rebuild.

3. Significant Increase in Oil Consumption

While all diesel engines consume a certain amount of oil during operation, a noticeable increase in oil usage is a major warning sign. If you find yourself adding oil more frequently between services or topping off more than a quart every 10 hours, this could indicate:

- Worn piston rings or cylinder liners

- Leaking valve stem seals

- Crankcase pressurization due to blow-by

- Oil entering the combustion chamber and burning with fuel

Excess oil consumption not only increases maintenance costs but also creates a risk for emissions violations, fouled injectors, turbo damage, and carbon buildup.

4. Drop in Fuel Efficiency

A declining fuel economy is a clear indicator that your engine is no longer operating at peak efficiency. This can result from:

- Loss of compression

- Faulty injectors

- Exhaust gas recirculation (EGR) inefficiencies

- Reduced combustion chamber sealing

When fuel is not combusted efficiently, more is required to maintain the same output. Over time, this inefficiency adds significant operational cost, especially in fleets or high-hour machines. A well-executed engine overhaul can restore original fuel efficiency by renewing piston-cylinder integrity and refreshing critical fuel and air delivery systems.

5. Unusual Engine Noises: Knocking, Rattling, or Tapping

Diesel engines are known for their characteristic sound, but any sharp or sudden change in engine noise should not be ignored. Abnormal noises could mean:

- Loose or worn connecting rod bearings

- Excessive piston-to-wall clearance

- Valve train wear or misalignment

- Timing issues

A knocking sound, especially under load, may indicate impending bearing failure. A rattling or clattering noise at idle could point to valve lash issues or cam wear. These symptoms are often early warnings of deeper mechanical problems that can be resolved through an overhaul before permanent damage occurs.

6. Metal Contamination in Oil Samples

Routine oil analysis is one of the best preventive maintenance tools available. An increase in certain metals in your oil sample can signal internal engine wear long before it becomes externally visible. For instance:

- Elevated iron may suggest cylinder liner or crankshaft wear.

- Aluminum can indicate piston skirt or bearing damage.

- Copper and lead often point to bearing shell wear.

- Chromium or molybdenum could signal valve train deterioration.

If your oil reports repeatedly show increasing metal concentrations, it’s time to plan for an overhaul. Catching the issue early can save your block and crankshaft from damage, allowing a standard rebuild rather than a full engine replacement.

7. Failed Emissions Testing or Excessive Exhaust Smoke

Engines that are no longer in optimal mechanical condition often produce higher emissions. You may observe black, white, or blue smoke from the exhaust, indicating issues such as:

- Poor combustion due to low compression

- Worn injectors or injector seals

- Burning oil from worn rings or valve guides

- Coolant leaks into the combustion chamber

In jurisdictions with strict emissions standards, failing a test can result in fines or operational restrictions. Even in unregulated environments, excessive smoke can harm surrounding equipment and reduce engine reputation. Rebuilding the engine restores clearances and ensures proper combustion, eliminating most smoke-related issues.

8. Repeated Repairs Without Lasting Results

If you’ve been chasing engine problems for months—replacing injectors, turbos, head gaskets, and sensors—without solving performance issues, it’s a strong sign that the core engine needs a reset. At a certain point, continued repairs become more expensive and time-consuming than performing an overhaul.

A comprehensive engine rebuild gives you a fresh start, eliminates compounding issues, and often costs less than the total sum of piecemeal repairs. It also provides a renewed confidence in your equipment’s reliability.

9. Seasonal Downtime or Scheduled Maintenance Windows

One of the best times to schedule an engine overhaul is during planned downtime. Marine vessels may have off-seasons; agricultural and industrial machines may be underutilized during certain months. Planning an overhaul during these periods minimizes impact on operations and allows for a controlled work environment, avoiding the pressures of emergency repair.

Many fleets implement overhaul cycles into their long-term maintenance strategy, aligning them with budget planning and equipment usage schedules.

10. Engine Operating in Harsh Environments

Engines operating in extreme heat, dusty conditions, or high-load environments will experience accelerated wear. For example:

- Mining and quarry operations

- Desert or tropical climate marine use

- Off-road construction equipment

- Remote power generation in variable temperatures

If your Cummins 6CTA operates under one or more of these conditions, you may need to consider an overhaul at an earlier hour interval. Adding oil sampling, vibration monitoring, and pre-overhaul inspections can help determine the right timing.

11. Customer or Regulatory Requirements

In some industries, customers require that engines meet certain performance criteria or be overhauled at defined intervals to maintain contracts or certifications. Examples include:

- Maritime vessel inspections

- Government and military contracting

- Emissions compliance for municipal equipment

If you operate under such constraints, overhauling your 6CTA at the correct interval not only ensures mechanical integrity but protects your operational eligibility.

2. Engine Overheating or Coolant Leaks

Repeated overheating or unexplained coolant loss can be symptoms of internal engine damage. Common causes include:

- Cracked head or block

- Blown head gasket

- Warped cylinder head

- Worn cylinder liners allowing combustion gas intrusion

Continuing to run the engine in this condition can cause irreversible damage. An overhaul that includes reconditioning or replacing the head and sealing surfaces is often the best path forward.

Final Thoughts: Proactive vs. Reactive Rebuilds

Waiting until your engine fails often results in higher costs, limited parts availability, and longer downtimes. On the other hand, a proactive engine overhaul lets you:

- Plan around your schedule

- Order a complete overhaul kit

- Work with experienced technicians

- Restore your engine to OEM condition

The Cummins 6CTA is a remarkably resilient engine, but every powerplant has a finite life. By understanding and acting on the signs above, you can ensure that your equipment continues to perform efficiently, reliably, and affordably.

If you’re experiencing any of these conditions—or simply want to restore performance before issues arise—Diesel Pro Power’s Cummins 6CTA Overhaul Kit is the proven solution to get you back to peak operation.

Get Your Diesel Pro Power, Inc. 6CTA Overhaul Kit

Diesel Pro Power, Inc. Cummins 6CTA overhaul kits are a great way to restore an aging Cummins 6CTA engine to its original condition. The kit typically contains all the parts and components necessary to complete a full rebuild of the engine, including pistons, liners, piston rings, piston pins, piston pin retainers, crankshaft bearings, connecting rod bearings, and upper and lower gasket sets. Additionally, the cost of the kit is usually lower than the cost of buying all the individual parts and components separately. If you are looking for a way to restore your Cummins 6CTA engine to its original state, a Diesel Pro Power, Inc. Cummins 6CTA overhaul kit is the way to go.

Additional Resources For The Cummins 6CTA

Marine Cummins 6CTA Component Maintenance Life

Cummins 6CTA 8.3 Marine Diesel Engine Specifications

A Comprehensive Guide to Cummins 6CTA Diamond Series Diesels 8.3 Parts and Maintenance

Buy Parts For Your Cummins 6CTA 8.3L

Guide To Buying A Cummins 6CTA Overhaul Kit

A Step-by-Step Guide to Installing a Cummins 6CTA Sea Water Pump

The Cummins 6CTA Marine Diesel Engine

Regular Service For Cummins 6CTA

Boats That Use The Cummins 6CTA

FAQ About The Cummins 6CTA Engine

Torque Specs For Cummins 6CTA 8.3

Cummins C Series Engine Comprehensive FAQ

Overview of Cummins C Series Engines (6C, 6CT, 6CTA) (1991 and 1994 Certification Levels)

Key Features of Cummins C Series Engines (6C, 6CT, 6CTA)

Tools and Preparation for Servicing Your Cummins 6C, 6CT, 6CTA

Engine Overhaul Basics for Cummins C Series Engines (6C, 6CT, 6CTA)

Comparing 1991 and 1994 Certification Levels for Cummins C Series Engines (6C, 6CT, 6CTA)

Understanding the Basics for Cummins 6C, 6CT, & 6CTA

Maintenance Essentials for Cummins 6C, 6CT, & 6CTA Engines

System Specific Servicing for Cummins 6C, 6CT, & 6CTA Engines

Advanced Repairs for Cummins 6C, 6CT, & 6CTA Engines

Certification Level Specific Insights for Cummins 6C, 6CT, & 6CTA Engines

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588