Cummins 6CTA Engine Parts - In-Frame Overhaul KIt Section

Loading...

Loading... Cummins 6CTA Engine Overhaul Kits and Parts Catalog

Complete Overhaul Solutions for Cummins 6CTA Engines

If you're rebuilding a Cummins 6CTA engine, you need more than just a basic set of replacement parts—you need a complete and trusted overhaul solution designed to restore performance, maintain durability, and reduce downtime. At Diesel Pro Power, we offer comprehensive overhaul kits for the Cummins 6CTA that are compatible with a wide range of CPL numbers, all backed by our decades of industry experience and 40,000+ satisfied customers worldwide.

Whether you're managing a marine vessel, powering an industrial generator, or running heavy-duty equipment, our overhaul kits and related engine components are selected to help you get back to work quickly and reliably.

Engine Overview: The Cummins 6CTA Platform

The Cummins 6CTA 8.3L is a turbocharged, aftercooled, inline 6-cylinder diesel engine. It's part of the "C Series" family, renowned for its balance of performance and longevity. Key features include:

-

Displacement: 8.3 liters

-

Configuration: Inline 6-cylinder

-

Aspiration: Turbocharged and aftercooled

-

Valve Arrangement: 12-valve or 24-valve (depending on variant)

-

Typical Applications: Marine propulsion, construction equipment, industrial generators, and agricultural machinery

The 6CTA is closely related to the 6C and 6CT engines. Many parts are cross-compatible, but it’s critical to select components that match your specific CPL number and engine configuration. Our overhaul kits are organized by CPL groupings to make this process easier and more accurate.

Overhaul Kits by CPL Compatibility

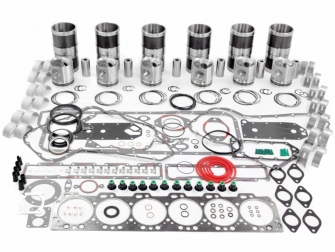

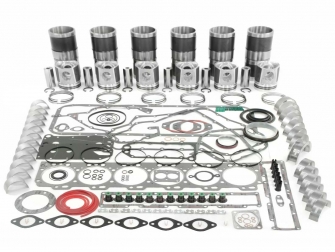

Each Cummins 6CTA overhaul kit listed below includes a complete set of high-quality components to restore compression and engine performance to factory levels. Kits generally include:

-

Pistons (usually one-piece or articulated)

-

Piston rings

-

Cylinder liners (if applicable)

-

Main bearings

-

Rod bearings

-

Thrust washers

-

Full upper and lower gasket sets

We organize these kits by CPL (Control Parts List) to help you match parts precisely with your engine build.

Overhaul Kit for Cummins 6CTA (CPL 602, 603, 753, 819, 828, 829...)

Compression Ratio: Typically 17.0:1

This kit includes one-piece pistons, known for improved thermal stability and longevity. These CPLs are found in industrial, marine, and off-highway applications where reliability under load is crucial.

Overhaul Kit for Cummins 6CTA (CPL 604, 605, 754, 755, 830, 831...)

Compression Ratio: Typically 16.5:1

Ideal for high-altitude or high-heat operating environments, this compression ratio balances power and fuel efficiency while reducing combustion stress.

Overhaul Kit for Cummins 6CTA (CPL 1216, 1217, 1221, 1282, 1366...)

Compression Ratio: May vary slightly depending on application

This overhaul kit fits a wide range of stationary and mobile industrial power applications. It's frequently used in gensets, pumping stations, and commercial marine vessels.

Overhaul Kit for Cummins 6CTA (CPL 1845, 1846, 1943, 2007, 2054...)

Compression Ratio: Typically 17.3:1

These CPL numbers are associated with newer model configurations and often used in high-duty-cycle equipment. The included components are designed to match updated cylinder head and piston designs.

Overhaul Kit for Cummins 6CTA (CPL 2241, 2299, 2964, 8578)

Compression Ratio: High-efficiency 17.5:1

The highest compression ratio among these groupings, this kit is intended for engines operating in emissions-regulated environments or under strict fuel consumption controls.

Why Compression Ratio Matters

The compression ratio in a diesel engine is the ratio between the total cylinder volume when the piston is at the bottom of its stroke (BDC) and the volume when it is at the top (TDC). A higher ratio typically results in better fuel efficiency and more power—but can also increase combustion temperatures. Matching the right compression ratio to your CPL ensures your engine performs to design expectations without premature wear.

Supporting Components for a Complete 6CTA Rebuild

A successful overhaul goes beyond pistons and bearings. Below are critical supporting parts offered by Diesel Pro Power, each carefully selected for compatibility with Cummins 6CTA engines.

Piston Cooling Nozzles

These nozzles spray engine oil under the piston crowns to dissipate heat, especially important for turbocharged engines with one-piece pistons.

-

Variants Available: 1.22" and 1.73" length

-

Quantity Needed: 6 per engine

-

Applications: 6CTA, 6CT, ISC, QSC, QSL, ISL

Make sure to match nozzle length with your engine’s original equipment.

Crankshaft Seal Kits (Front and Rear)

Front and rear seal kits are essential when separating the engine from a flywheel or transmission. Our kits include both the seal and wear sleeve for proper oil retention.

-

Front Seal Kits: Available for standard and non-automotive configurations

-

Rear Seal Kits: Includes options for wet clutch housings

-

Why Replace? Prevents crankcase oil leakage post-rebuild

Expansion Plug Kits for Engine Block

Block expansion plug kits ensure coolant sealing in core passages after reassembly. These are required anytime the engine has been hot-tanked or machined.

Turbo Mounting Gaskets and Exhaust Gaskets

Proper sealing of your turbo and exhaust manifolds is critical to avoiding boost pressure leaks or exhaust soot buildup after rebuilds.

-

Turbo Mounting Gaskets: For water-cooled turbo applications

-

Exhaust Gasket: Fits outlet connection on 6CTA and related engines

Essential Filters to Replace During Overhaul

No engine rebuild should be completed without also installing new filters. Doing so ensures that contaminants from the rebuild process don’t enter the lubrication or fuel systems.

Cummins Fuel Filters (Spin-On and Cartridge)

We offer multiple filter sizes depending on your application:

-

Standard Diesel Fuel Filters: Available in various thread sizes and flow ratings

-

Fuel Filter with Water Separator: Removes water contamination from fuel, extending injector life

Oil Filter Options and Filter Tools

Replacing your oil filter after break-in is essential. We also offer:

-

Oil Filter Removal Wrenches to fit filters ranging from 4-5 inches

-

Fuel Filter Wrenches for 3–4 inch filters

These tools help prevent damage to the filter housing during removal and installation.

Engine Calibration and Assembly Tools

After rebuilding the bottom end, accurate valve calibration and ring assembly are key. We recommend the following tools:

Valve Feeler Gauge (.002”–.025”)

Used to precisely set intake and exhaust valve clearances. Improper clearance can lead to:

-

Hard starting

-

Reduced power

-

Valve damage over time

Piston Ring Assembly Tool

This specialized tool assists in compressing rings during piston installation. It reduces the risk of scoring cylinder walls or damaging ring sets.

Optional Upgrades and Final Touches

While not mandatory, the following items are commonly purchased alongside Cummins 6CTA overhaul kits to support a more robust rebuild:

Vibration Isolators (4 per engine)

Replaces worn or collapsed engine mounts, reducing vibration and preventing premature wear of gaskets, seals, and accessories.

Temperature Switches and Gauges

Post-rebuild, it's essential to monitor your engine's operating conditions. We provide:

-

Temperature Switches that close at 205°F (commonly used with alarms)

-

Mechanical and Electrical Gauges: Available in 12V and 24V options, with or without alarms

These indicators help prevent overheating, low oil pressure, or other failure conditions during break-in or long-term operation.

What Sets Diesel Pro Power Apart?

We don’t just sell engine parts—we provide trusted rebuild solutions. Here’s why professionals choose us:

-

CPL-Based Accuracy: Every overhaul kit is matched by CPL for perfect compatibility

-

Global Reach: Fast international shipping with tracking and customs support

-

Experienced Support: Our team can help you select the correct kit for your configuration

-

Thousands of Verified Reviews: 40,000+ satisfied customers and counting

When Should You Rebuild Your 6CTA?

Typical signs it’s time to overhaul your 6CTA engine include:

-

Excessive blow-by or crankcase pressure

-

Blue or black exhaust smoke

-

Drop in compression or cylinder leakage

-

Low oil pressure despite new pump or oil

-

Excessive coolant or oil consumption

If your engine shows these symptoms and has surpassed 10,000–15,000 hours of use, a rebuild is often the most cost-effective solution.

Common CPLs Covered by Our Kits

Here’s a summary of some CPL groups we support:

-

CPL 602–605: Early industrial and construction models

-

CPL 753–755, 828–831: Mid-production marine and genset configurations

-

CPL 1216–1222, 1273–1282: Generator sets and agricultural machinery

-

CPL 1845–2057: Fleet and stationary applications

-

CPL 2241–2964: Late-production, high-efficiency engines

If your CPL is not listed here, contact our customer service team for support—we likely carry it or can help you source it.

Final Notes

Rebuilding a Cummins 6CTA engine requires precision, experience, and the right parts. At Diesel Pro Power, we help professionals and operators around the world complete successful overhauls that extend engine life and restore performance.

If you’re unsure which kit fits your CPL, or need help selecting tools and accessories, our team is ready to assist. With thousands of successful rebuilds under our belt, we can guide you from teardown to reassembly—confidently and quickly.

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588