November 7, 2024

Key Functions For The Cylinder Head In A Detroit Diesel 149 Engine: Housing Exhaust Valves, Fuel Injectors, and Cooling Systems

Key Functions of the Cylinder Head

Common Issues: Addressing Wear, Valve Clearance, and Cylinder Head Replacement In The Detroit Diesel 149 Series Engine

Wear on Exhaust Valves and Seats

Maintaining Proper Valve Clearance

Injector Wear and Carbon Buildup

Cooling Passage Blockages

Cylinder Head Cracks and Warping

Head Gasket Failure For Detroit Diesel 149 Series Engines (8V149, 12V149, 16V149)

Read More

November 7, 2024

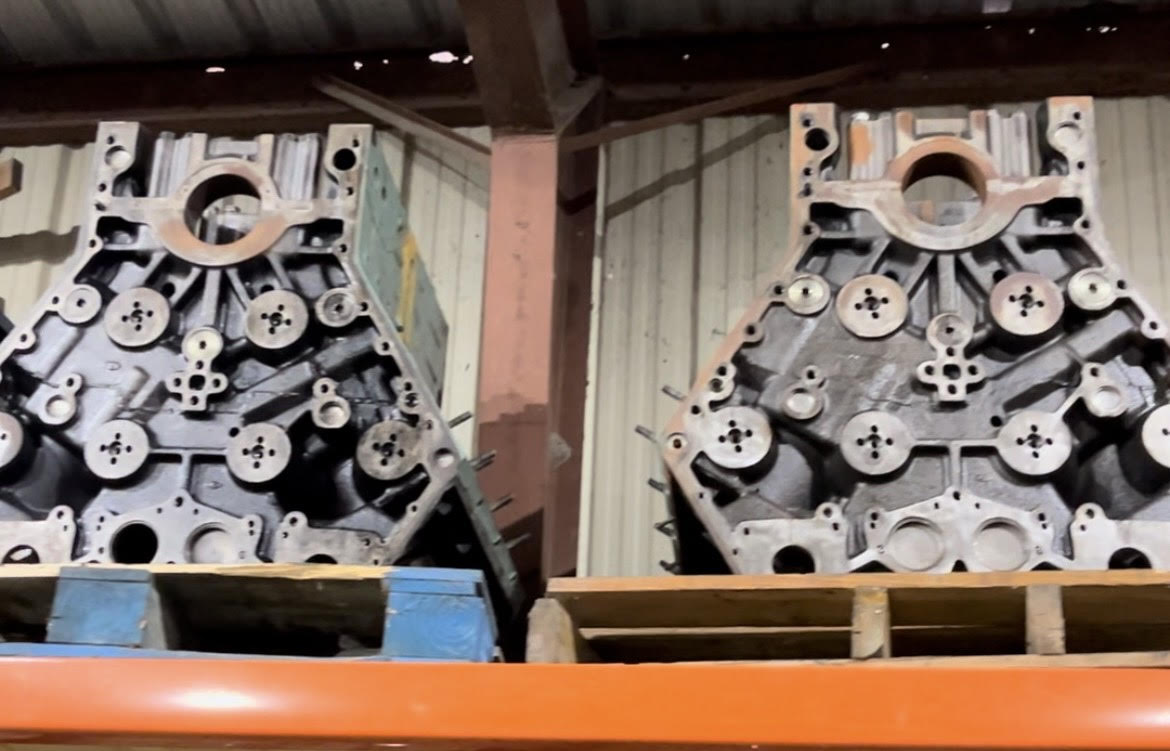

Structure and Role: The Detroit Diesel 149 Engine’s Main Frame

Heavy-Duty Cylinder Block Construction

Housing and Support for Critical Components

Integrated Cooling and Lubrication Systems

Structural Integrity and Load Distribution

Maintenance Tips: Ensuring Structural Integrity and Performance for Your Detroit Diesel 149 Cylinder Block

Inspecting for Cracks and Fractures

Checking Bearing Caps for Wear

Monitoring Bolt Torque and Thread Condition

Torque Specs By Component

Thread Size

Torque (lb-ft)

Torque (N·m)

Cleaning Cooling and Lubrication Passages

Ensuring Surface Flatness

Cleaning and Testing: Maintaining Optimal Condition of the Cylinder Block

Solvent Baths for Thorough Cleaning

Process:

Post-Bath Scrubbing:

Benefits:

Steam Cleaning to Clear Residual Buildup

Pressure Testing to Detect Leaks and Weaknesses

Magnetic Particle Inspection (MPI) for Crack Detection

Rust Prevention and Protective Coatings

Read More

November 6, 2024

Clean Workspace: Importance of a Clean, Organized Area

Protection of Sensitive Components:

Organized Surfaces

Regular Cleaning Routines

Storage of Parts and Supplies

Contamination Prevention

Tool Preparation: Recommendations for Quick, Organized Access

Read More

November 6, 2024

Battery Disconnect: Precautions to Avoid Accidental Starting

Complete Power Isolation

Use of Lockout-Tagout (LOTO)

Discharge Stored Electrical Energy

Disconnecting Additional Power Sources

Conclusion

Proper Lifting Techniques: Securing Heavy Components Correctly

1. Using Engine Lifter Brackets as Recommended

2. Choosing the Right Lifting Equipment

3. Securing Components Before Lifting

4. Avoiding Manual Lifting of Heavy Parts

5. Team Lifting for Medium-Weight Components

6. Ensuring Workplace Safety

Conclusion

Conclusion Of Engine Safety For Detroit Diesel 149 Series Engines (8V149, 12V149, 16V49)

Read More

November 6, 2024

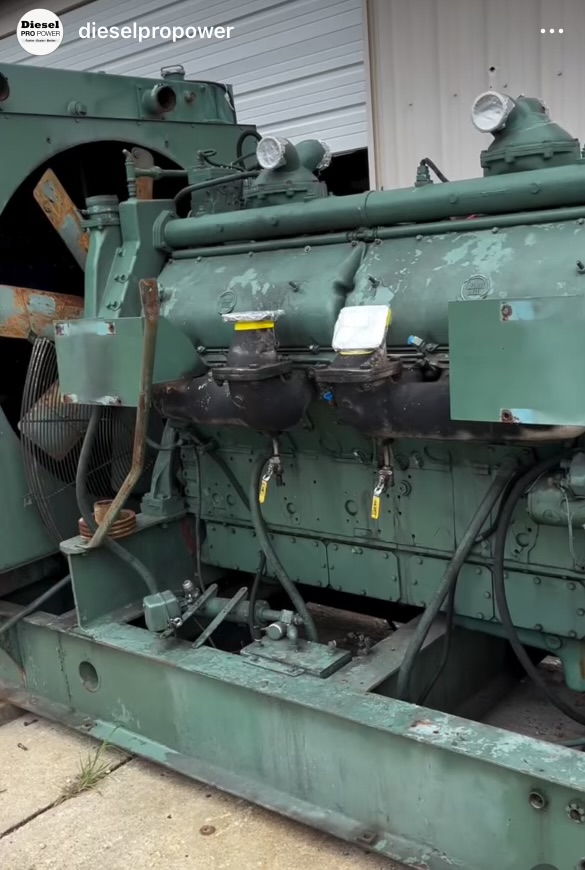

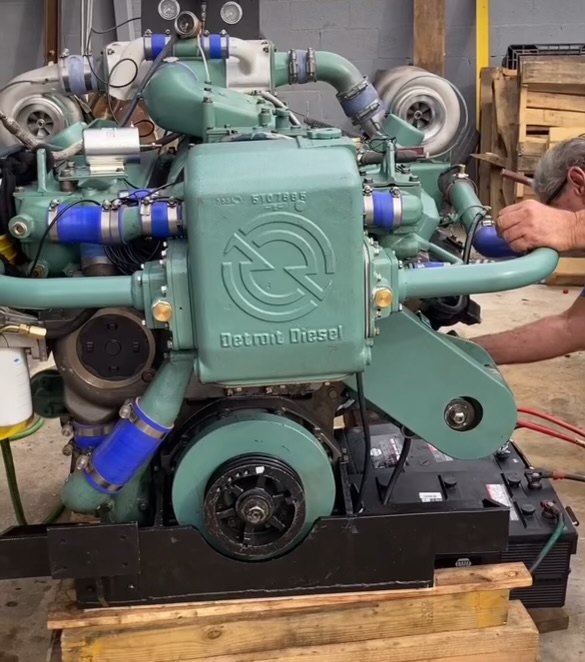

The Origins of Detroit Diesel and Its Impact on Marine Applications

Detroit Diesel’s Engine Series and Marine Success

71 Series:

53 Series:

92 Series:

149 Series:

Key Advantages for the Marine Industry

Two-Stroke Diesel Technology: Why It Was Ahead of Its Time

The Enduring Legacy of Two-Stroke Engines in Marine Applications

Read More

November 6, 2024

Protective Gear Gear For Detroit Diesel 149 Series Engines (8V149, 12V149, 16V149)

Eye Protection:

Gloves and Hand Protection:

Hearing Protection:

Protective Clothing and Footwear:

Cautions With Moving Parts In Detroit Diesel 149 Series Engines (8V149, 12V149, 16V149)

Engine Off and Battery Disconnected:

Avoiding Loose Clothing and Jewelry:

Using Guards and Shields:

Chemical Handling For Detroit Diesel 149 Series Engines (8V149, 12V149, 16V149)

Proper Ventilation:

Handling Solvents Safely:

Storing and Disposing of Chemicals:

Avoiding Skin Contact and Ingestion:

Read More

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588