Parts Catalog Main Page for Cummins ISB Marine Engine

Cummins ISB 4.5 & Related Components

Cummins ISB 5.9 & Related components

Cummins ISB 6.7 & Related Components

Parts Catalog Main page for Cummins QSB Marine Engine

Cummins QSB 4.5 & Related Components

Cummins QSB 5.9 & Related Components

Cummins QSB 6.7 & Related Components

Cummins QSB 7.0 & Related Components

When operating Cummins ISB and QSB engines, encountering performance issues is inevitable over time, especially if the engine is subjected to harsh conditions or lacks regular maintenance. Identifying and diagnosing the root cause of engine problems is critical for minimizing downtime and preventing costly repairs. This guide will cover some of the most common engine symptoms—engine won’t start, excessive smoke from the exhaust, engine overheating, and unusual engine noises—along with their potential causes and diagnostic approaches.

1. Engine Won’t Start

A non-starting engine is one of the most common and frustrating problems faced by operators and mechanics. This issue can stem from electrical faults, fuel system malfunctions, mechanical failures, or sensor errors. Systematically troubleshooting the issue can help identify the root cause quickly.

Common Causes of a No-Start Condition

A. Fuel System Issues

- Empty Fuel Tank or Contaminated Fuel: It sounds simple, but low or bad-quality fuel is often overlooked.

- Air in the Fuel System: This can occur due to leaks in fuel lines or improper bleeding after maintenance.

- Clogged Fuel Filters: Restricted fuel flow can prevent the engine from receiving adequate fuel for combustion.

- Faulty Fuel Pump: A malfunctioning lift pump or injection pump will fail to deliver fuel at the necessary pressure.

- Injector Problems: Stuck-open or clogged fuel injectors disrupt proper fuel atomization.

B. Electrical System Failures

- Dead Battery: A weak or dead battery won’t supply enough power to crank the engine.

- Corroded or Loose Battery Terminals: Poor connections can impede electrical flow.

- Faulty Starter Motor or Solenoid: A failed starter system can prevent the engine from turning over.

- Blown Fuses or Faulty Relays: Electrical circuits may be interrupted due to blown fuses or defective relays.

C. Sensor or ECM Issues

- Faulty Crankshaft or Camshaft Position Sensors: These sensors are critical for timing fuel injection and ignition.

- ECM Malfunction: A corrupted or damaged Electronic Control Module (ECM) can prevent the engine from starting.

- Incorrect Security Settings: In vehicles with security features, immobilizer malfunctions can block engine start.

D. Mechanical Problems

- Low Compression: Worn piston rings, damaged valves, or a blown head gasket can reduce compression to a level where ignition can’t occur.

- Timing Issues: Problems with the timing belt or chain can cause the valves and pistons to fall out of sync.

Troubleshooting Steps for No-Start Issues

- Check the Basics:

- Verify that there’s fuel in the tank and that the fuel is clean and uncontaminated.

- Check the battery voltage (12.6 volts or higher when fully charged).

- Listen for Sounds:

- Clicking sounds may indicate a bad starter solenoid.

- No sound could point to a dead battery or faulty ignition switch.

- Inspect Fuel Delivery:

- Prime the fuel system to remove air.

- Check for fuel at the injectors by cracking an injector line while cranking.

- Scan for Diagnostic Trouble Codes (DTCs):

- Use a diagnostic tool to read fault codes from the ECM.

- Use a diagnostic tool to read fault codes from the ECM.

- Compression Test:

- Perform a compression test to verify engine health.

- Perform a compression test to verify engine health.

Starter & Related Components for Cummins ISB 4.5 Engine

Starter & Related Components for Cummins ISB 5.9 Engine

Starter & Related Components for Cummins ISB 6.7 Engine

Starter & Related Components for Cummins QSB 4.5 Engine

Starter & Related Components for Cummins QSB 5.9 Engine

Starter & Related Components for Cummins QSB 6.7 Engine

Starter & Related Components for Cummins QSB 7.0 Engine

2. Excessive Smoke from the Exhaust

While some smoke is normal for diesel engines, excessive smoke often signals an underlying problem. The color of the smoke can help pinpoint the issue—white, black, or blue smoke each indicate different types of malfunctions.

A. White Smoke

White smoke usually consists of unburned fuel or coolant entering the exhaust system.

Common Causes of White Smoke:

- Cold Starts: In cold weather, white smoke can be normal due to unburned fuel, especially if the engine hasn’t warmed up yet.

- Faulty Fuel Injectors: Poor spray patterns cause incomplete combustion.

- Low Compression: Damaged piston rings, valves, or cylinder walls can prevent proper combustion.

- Coolant Leaks: A blown head gasket, cracked cylinder head, or warped engine block can allow coolant into the combustion chamber.

Troubleshooting White Smoke:

- Smell the Smoke: A sweet smell may indicate coolant, while a fuel-like odor suggests unburned diesel.

- Check Coolant Levels: Low coolant could indicate an internal leak.

- Perform a Compression Test: Low readings point to mechanical issues.

- Inspect Injectors: Ensure they’re not leaking or clogged.

B. Black Smoke

Black smoke indicates incomplete combustion, usually due to too much fuel or not enough air.

Common Causes of Black Smoke:

- Air Intake Restrictions: Clogged air filters or blocked intercoolers reduce airflow.

- Faulty Turbocharger: A failing turbo can’t supply enough boost, leading to poor combustion.

- Bad EGR Valve: A stuck-open Exhaust Gas Recirculation (EGR) valve recirculates too much exhaust, diluting oxygen levels.

- Excessive Fuel Delivery: Faulty injectors, incorrect fuel mapping, or high fuel pressure.

Troubleshooting Black Smoke:

- Inspect the Air Intake System: Check filters, hoses, and turbo components for blockages.

- Check Turbo Operation: Ensure proper boost pressure.

- Test Fuel Injectors: Look for signs of over-fueling or leaks.

C. Blue Smoke

Blue smoke indicates burning oil, which could be due to worn engine components or issues with the turbocharger.

Common Causes of Blue Smoke:

- Worn Piston Rings: Allow oil to seep into the combustion chamber.

- Valve Seal Leaks: Oil leaks past seals into the intake or exhaust ports.

- Overfilled Oil: Too much oil can lead to it entering the combustion process.

- Turbocharger Issues: Failing seals allow oil to leak into the intake side.

Troubleshooting Blue Smoke:

- Check Oil Levels: Ensure they’re within the recommended range.

- Inspect for Oil Leaks: Around the turbo, valves, and seals.

- Compression and Leak-Down Tests: To assess internal engine wear.

Injector & Related Components for Cummins ISB 4.5 Engine

Injector & Fuel Pump Related Components for Cummins ISB 5.9 Engine

Injector & Related Components for Cummins ISB 6.7 Engine

Injector & Fuel Pump Related Components for Cummins QSB 4.5 Engine

Injector & Fuel Pump Related Components for Cummins QSB 5.9 Engine

Injector & Fuel Pump Related Components for Cummins QSB 6.7 Engine

Injector & Fuel Pump Related Components for Cummins QSB 7.0 Engine

3. Engine Overheating Issues

An overheating engine can lead to catastrophic damage if not addressed promptly. It’s essential to understand the cooling system and diagnose issues early.

Common Causes of Overheating:

A. Cooling System Failures

- Low Coolant Levels: Due to leaks, evaporation, or improper filling.

- Blocked Radiator: Dirt, debris, or corrosion reduces heat dissipation.

- Faulty Thermostat: If stuck closed, it restricts coolant flow.

- Water Pump Failure: Insufficient coolant circulation leads to hotspots.

B. External Factors

- Heavy Loads: Towing or climbing steep grades can overwhelm the cooling system.

- Blocked Airflow: Debris in front of the radiator reduces cooling efficiency.

C. Mechanical Issues

- Blown Head Gasket: Allows combustion gases into the cooling system.

- Timing Issues: Incorrect timing causes excess heat buildup.

Troubleshooting Overheating Issues:

- Check Coolant Levels: Look for leaks around hoses, radiator, and water pump.

- Inspect the Radiator: Use a flashlight to check for blockages or damage.

- Test the Thermostat: Place it in hot water and see if it opens at the correct temperature.

- Cooling System Pressure Test: Detects internal leaks or compromised hoses.

Cooling System & Related Components for Cummins ISB 4.5 Engine

Cooling System & Related Components for Cummins ISB 5.9 Engine

Cooling System & Related Components for Cummins ISB 6.7 Engine

Cooling System & Related Components for Cummins QSB 4.5 Engine

Cooling System & Related Components for Cummins QSB 5.9 Engine

Cooling System & Related Components for Cummins QSB 6.7 Engine

Cooling System & Related Components for Cummins QSB 7.0 Engine

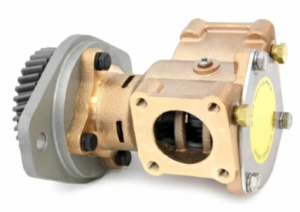

Raw Water Pump & Related Components for Cummins QSB 5.9 Engine

Raw Water Pump & Related Components for Cummins QSB 6.7 Engine

Raw Water Pump & Related Components for Cummins QSB 7.0 Engine

4. Unusual Engine Noises

Unusual noises often indicate developing mechanical issues. Identifying the type of noise, its location, and operating conditions helps diagnose the root cause.

Common Types of Unusual Noises:

A. Knocking or Pinging

A knocking sound is often due to abnormal combustion or mechanical wear.

- Fuel-Related Issues: Low cetane fuel causes improper combustion.

- Timing Problems: Incorrect injector timing or advanced ignition.

- Worn Bearings: Rod or main bearings wearing out due to poor lubrication.

B. Ticking or Clicking

A ticking sound usually comes from the valvetrain or fuel system.

- Valve Lash Issues: Improper clearance between valves and rocker arms.

- Injector Problems: High-pressure injectors can click during operation.

- Low Oil Pressure: Insufficient lubrication increases valve noise.

C. Whining or Whistling

A high-pitched whining often relates to the turbocharger or belts.

- Turbo Issues: Bearing failure causes whining under acceleration.

- Belt Problems: Worn or loose serpentine belts can create a whining noise.

D. Grinding or Rattling

A grinding noise signals severe mechanical issues.

- Transmission or Flywheel Damage: Damaged gears or loose flywheel bolts.

- Timing Gear Issues: Worn gears causing metal-on-metal contact.

Troubleshooting Engine Noises

- Isolate the Noise: Use a mechanic’s stethoscope to pinpoint the source.

- Check Oil Levels: Low oil can cause valvetrain noise.

- Inspect External Components: Check pulleys, belts, and accessories.

- Perform Engine Diagnostics: Compression tests and visual inspections may reveal internal damage.

Conclusion

Recognizing and diagnosing common engine symptoms in Cummins ISB and QSB engines is essential for efficient maintenance and repair. By understanding the root causes of issues like no-start conditions, excessive smoke, overheating, and unusual noises, operators and technicians can apply targeted troubleshooting methods to restore optimal performance. Regular maintenance, coupled with a systematic diagnostic approach, minimizes downtime, extends engine life, and ensures safe operation.

Parts Catalog Main Page for Cummins ISB Marine Engine

Cummins ISB 4.5 & Related Components

Cummins ISB 5.9 & Related components

Cummins ISB 6.7 & Related Components

Parts Catalog Main page for Cummins QSB Marine Engine

Cummins QSB 4.5 & Related Components

Cummins QSB 5.9 & Related Components

Cummins QSB 6.7 & Related Components

Cummins QSB 7.0 & Related Components

Free US Calls: 1-888-433-4735

Free US Calls: 1-888-433-4735 International: 305-545-5588

International: 305-545-5588